Paint brushing device for wood surface treatment

A wood surface and painting technology, applied in the field of painting, can solve the problems of high labor intensity, large paint diffusion surface, waste, etc., and achieve the effect of wide application range and high painting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

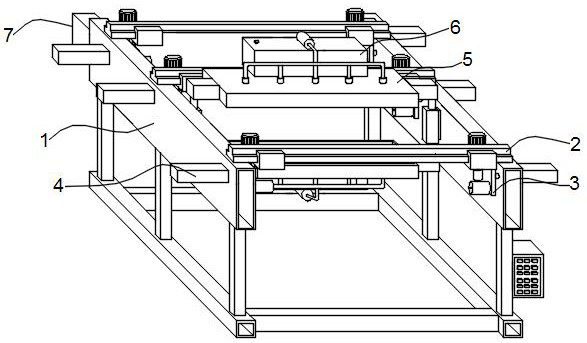

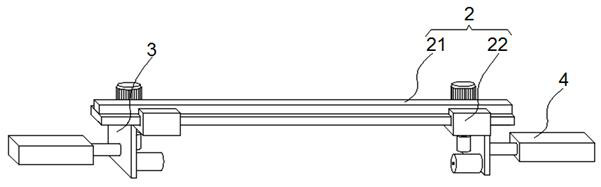

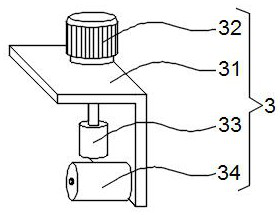

[0032] see figure 1 , the present embodiment provides a paint brushing device for wood surface treatment, which includes a frame 1, at least three lateral displacement assemblies 2 fixedly installed on the frame 1, a transmission device fixedly installed on each lateral displacement assembly 2 Structure 3, a plurality of electric push rods 4 symmetrically fixedly installed on both sides of the frame 1, a paint protection structure 5 fixedly installed inside the frame 1, and two paint spraying structures 6 symmetrically fixedly installed on the paint protection structure 5. In this embodiment, a host controller is installed on the rack 1, which is used to control the start-stop action of the driving device in this embodiment. The host controller is a common device in the prior art, so it will not be described in detail.

[0033] The painting device also includes two drying mechanisms 7, which are symmetrically and fixedly installed at the rear end of the frame 1. In this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com