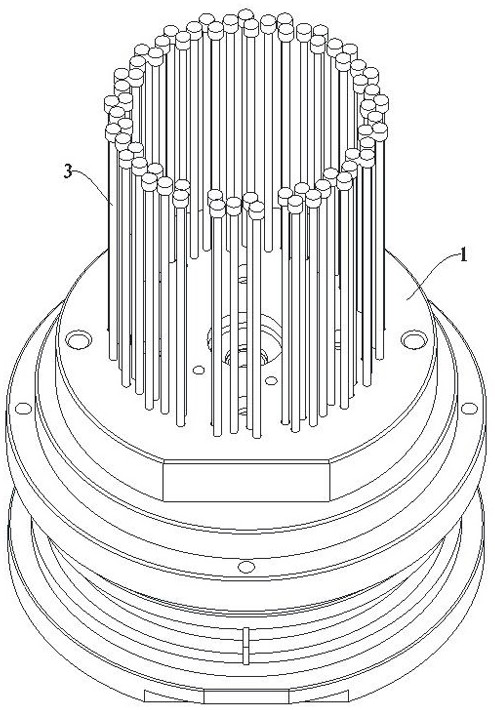

Dynamic balance machining die, adjusting method and operating method

A technology for processing molds and moving molds, applied in the field of dynamic balancing processing molds and adjustment, can solve the problems of unbalanced fans, difficult to ensure accuracy, low processing efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

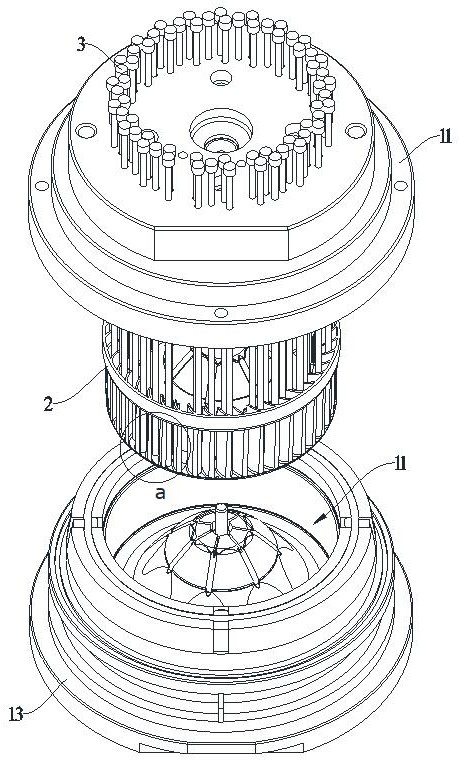

Embodiment 1

[0071] A method for adjusting a dynamic balance processing mold, comprising the following steps:

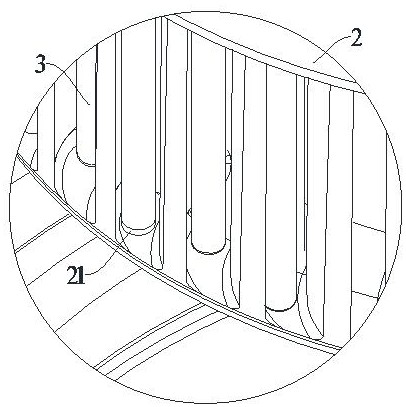

[0072] The first step is to set up 63 adjustment components 3, and label them in order, and make trial samples. Set the centrifugal balancing machine to the weighting method for calculation, and it is calculated that the samples need to be formed at the adjustment components 3 labeled a, b, and c. The mass of the balance part 21 is M a =3g, M b =1g and M c = 1g, the quality of the balance parts 21 that need to be formed at the remaining 60 adjustment components 3 is 0, and the quality data and the adjustment components 3 are recorded in one-to-one correspondence.

[0073] In the second step, the length H=M / (ρπR 2 ), where ρ is the density of the sample, ρ=1.13g / cm³, R is the radius of the balance part 21, R=0.5cm, bring in the above data and take two decimal places to get H a =3.38cm, H b =1.12cm, H c =1.12cm,.

[0074] In the third step, M a Correspondingly use the adjus...

Embodiment 2

[0078] A method for adjusting a dynamic balance processing mold, comprising the following steps:

[0079] The first step is to set 63 adjustment components 3, and label them in order, and make trial samples. Set the centrifugal balancing machine to the de-weighting method for calculation, and calculate the samples that need to be formed at the adjustment components 3 labeled d and e. The mass of the balance part 21 is respectively M d =-1g and M e =-1g, the quality of the balance parts 21 that need to be formed at the remaining 61 adjustment components 3 is 0, and the quality data and the adjustment components 3 are recorded in one-to-one correspondence.

[0080] In the second step, calculate the length H=M / (ρπR of the balance portion 21 at d and e places by mass data 2 ), where ρ is the density of the sample, ρ=1.13g / cm³, R is the radius of the balance part 21, R=0.5cm, bring in the above data and take two decimal places to get H d =-1.12cm, H e =-1.12cm.

[0081] In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com