Wear-free laminated spiral dewatering equipment with detachable driving device

A driving device, wear-free technology, applied in water/sludge/sewage treatment, chemical instruments and methods, sludge treatment, etc., can solve the problem of inability to install and disassemble, inability to observe normally, and the limit hole is subjected to large force and other problems, to achieve the effect of improving service life, convenient disassembly and installation, and smooth filter channel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

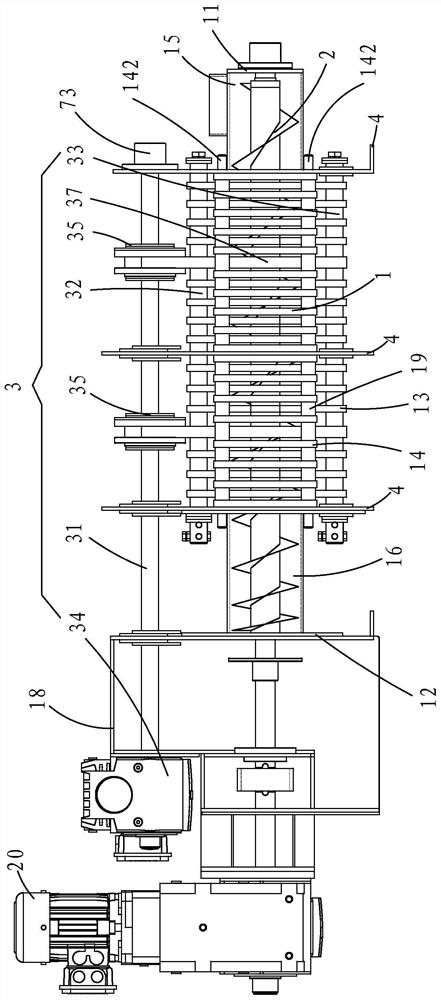

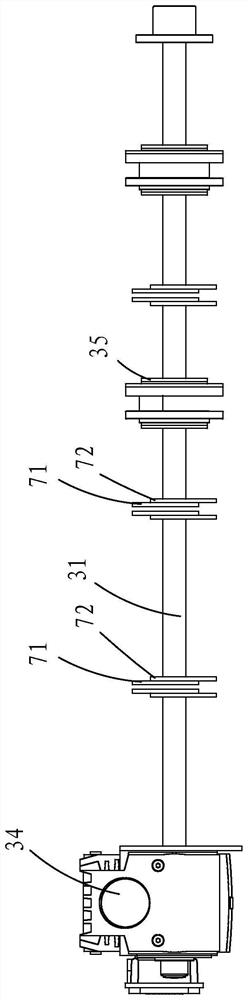

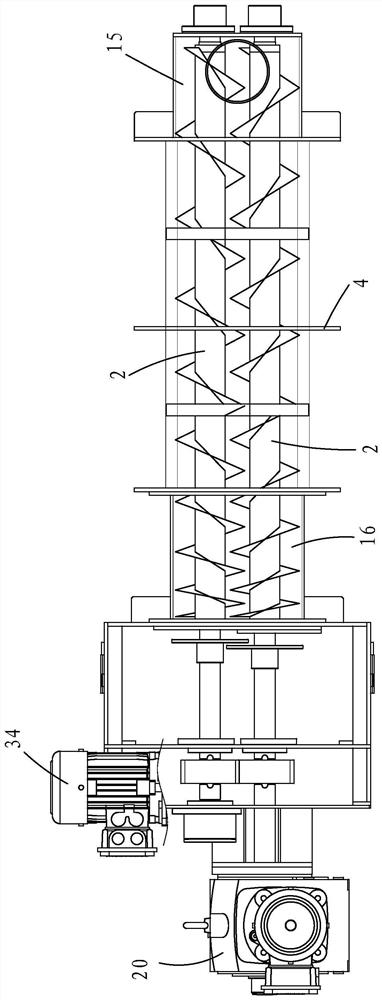

[0060] Such as Figure 1 to Figure 9 As shown, a laminated spiral solid-liquid separator with a detachable driving device includes: a filter cavity 1 , a screw shaft 2 , a driving device 3 , and a plurality of support plates 4 .

[0061] The filter cavity 1, the screw shaft 2 and the driving device 3 are supported and positioned by a plurality of support plates 4; the screw shaft 2 runs through the filter cavity 1; the two ends of the filter cavity 1 are the feed end 11 and the discharge end respectively 12. The feed end 11 of the filter cavity 1 is provided with a mud box 15 , and the discharge end 12 of the filter cavity 1 is provided with a mud box 18 .

[0062] The filter chamber 1 includes two groups of closed ring sheets, the first closed ring sheet group 13 (movable ring) moves under the drive of the drive device 3, and the four holes on the second closed ring sheet group 14 (fixed ring) 141 is fixed to the support plate 4 by the fixing ring pillar 142 and remains sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com