Light prefabricated stair and manufacturing method thereof

A manufacturing method and lightweight technology, applied to chemical instruments and methods, stairs, manufacturing tools, etc., can solve the problems of high labor intensity, low efficiency, uneven stress on the steel cage, etc., to increase connectivity and integrity, Effect of improving impact strength and improving load transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

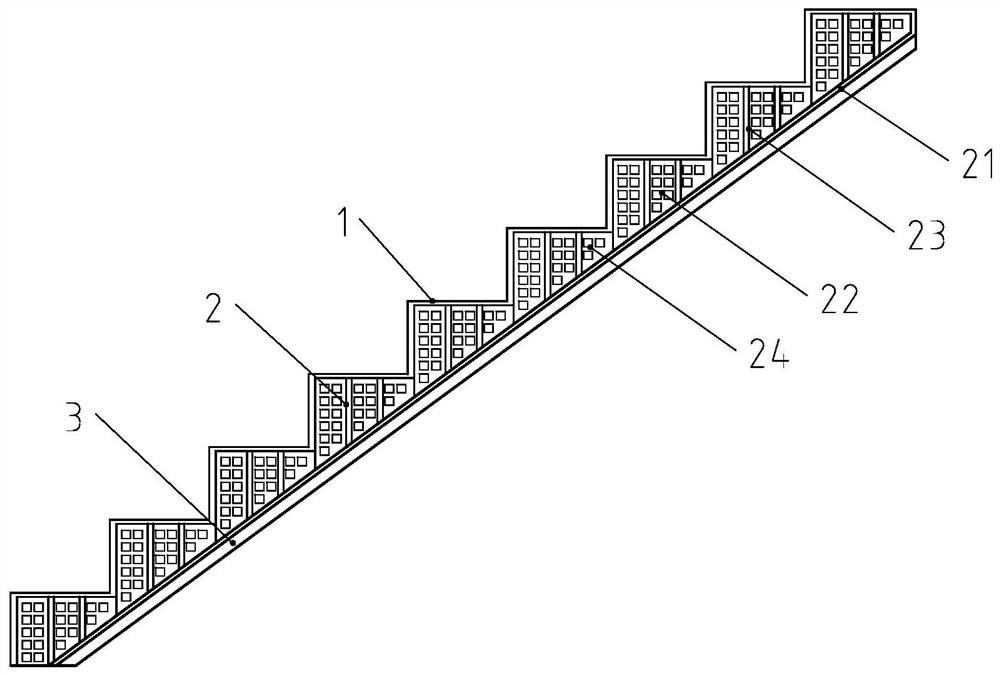

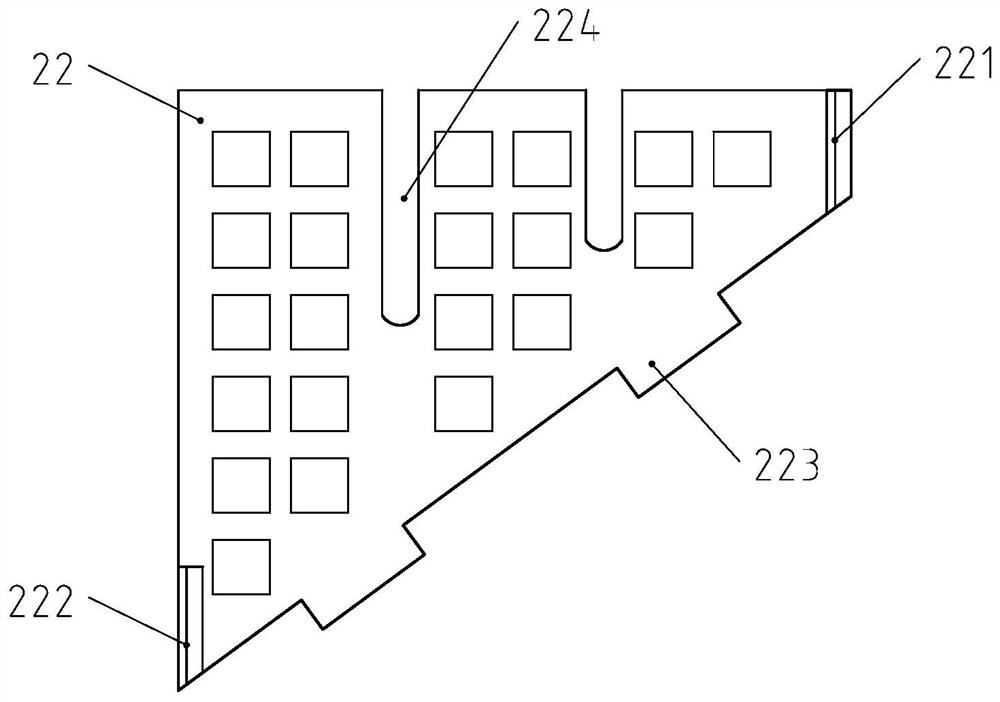

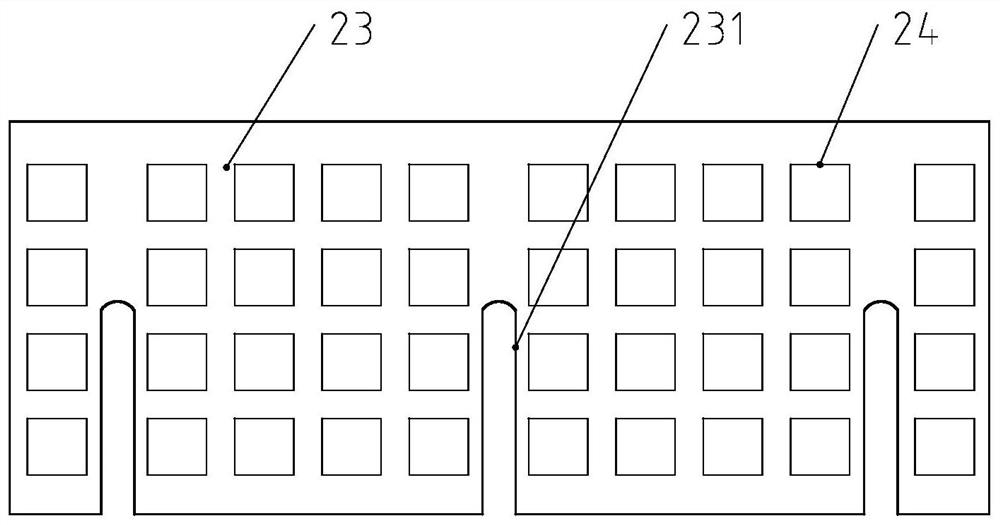

[0039] Such as figure 1 The shown lightweight prefabricated staircase includes a concrete staircase main body 1 and a plate-type composite skeleton 2 arranged in the concrete staircase main body. The main body of the concrete staircase 1 is formed by pouring foamed concrete 3. The panel composite skeleton 2 includes a bottom plate 21, several support plates 22 and several connecting plates 23. Several support plates 22 are continuously arranged on the surface of the bottom plate 21 along the length direction of the bottom plate 21. Several support plates 22 are arranged on the surface of the bottom plate 21 at intervals along the width direction of the bottom plate 21, and several connecting plates 23 are arranged at intervals along the length direction of the bottom plate 21 and intersect with several support plates 22. The unit hole 24 of the cloth.

[0040]Through the above technical solution, the plate-type combined skeleton 2 composed of the support plate 22, the connect...

Embodiment 2

[0042] Such as figure 1 The shown lightweight prefabricated staircase includes a concrete staircase main body 1 and a plate-type composite skeleton 2 arranged in the concrete staircase main body.

[0043] The main body of the concrete staircase 1 is formed by pouring foamed concrete 3. The panel composite skeleton 2 includes a bottom plate 21, several support plates 22 and several connecting plates 23. Several support plates 22 are continuously arranged on the surface of the bottom plate 21 along the length direction of the bottom plate 21. Several support plates 22 are arranged on the surface of the bottom plate 21 at intervals along the width direction of the bottom plate 21 , and several connecting plates 23 are arranged at intervals along the length direction of the bottom plate 21 and intersect with several support plates 22 .

[0044] The surface of each supporting plate 22 and the surface of each connecting plate 23 are provided with several uniformly distributed unit h...

Embodiment 3

[0058] A lightweight prefabricated staircase, the technical solution is the same as that of Embodiment 2, the difference is that:

[0059] Such as Figure 5 As shown, the unit hole 24 includes an upper unit hole 241 and a lower unit hole 242. The upper unit hole 241 is located on the surface of the support plate 22 away from the position of the bottom plate 21 and the surface of the connecting plate 23 is away from the position of the bottom plate 21. The lower unit hole 242 is located on the support plate 22. The surface of the plate 22 is close to the bottom plate 21 and the surface of the connecting plate 23 is close to the bottom plate 21. The aperture of the upper unit hole 241 is the same as the aperture of the lower unit hole 242, and the distance between the upper unit holes 241 is smaller than that between the lower unit holes 242. spacing.

[0060] Foamed concrete 3 includes the following components by weight: 420 parts of lightweight aggregate, 350 parts of cement,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com