Component testing device and method

A detection method and technology of components, applied in the field of image processing, can solve the problems of high cost of AOI equipment, lack of automation, easy to produce errors and omissions, etc., and achieve the effect of reducing labor costs, reducing the rate of false and missed detection, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to better understand the present invention, the present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments. In the following description, when detailed descriptions of existing prior art may obscure the subject matter of the present invention, such descriptions will be omitted here.

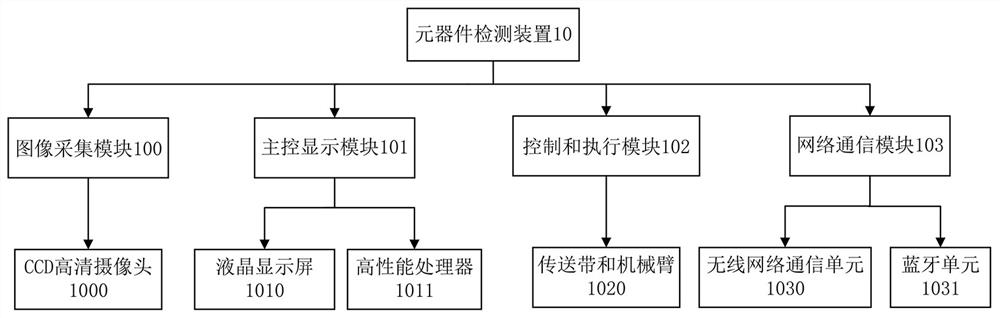

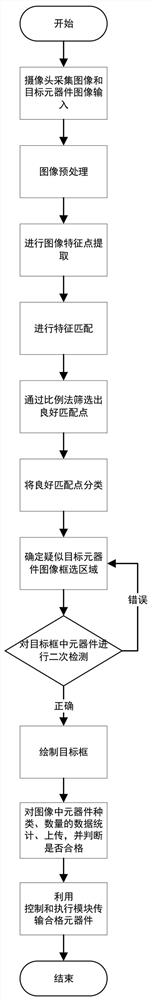

[0043] Such as figure 1 As shown, the component detection device 10 includes an image acquisition module 100 , a main control display module 101 , a control and execution module 102 , and a network communication module 103 . The present invention selects the detection of LED lamp beads on the lamp board as an embodiment of the present invention, which is used to illustrate the application process of the device of the present invention.

[0044] The image collection module 100 includes a CCD high-definition camera 1000 and a supporting data transmission cable for collecting images of LED lamp beads, and transmitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com