Method and device for strengthening NH3-SCR denitration of low-temperature flue gas by regulating and controlling autorotation of catalyst

A technology of NH3-SCR and low-temperature flue gas, which is applied in the field of air pollution control, can solve the problems of reduced service life, uneven distribution of flue gas flow field, and influence on denitrification efficiency, so as to improve the anti-toxicity and water resistance, and the probability of collision adsorption Improve and improve the effect of denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

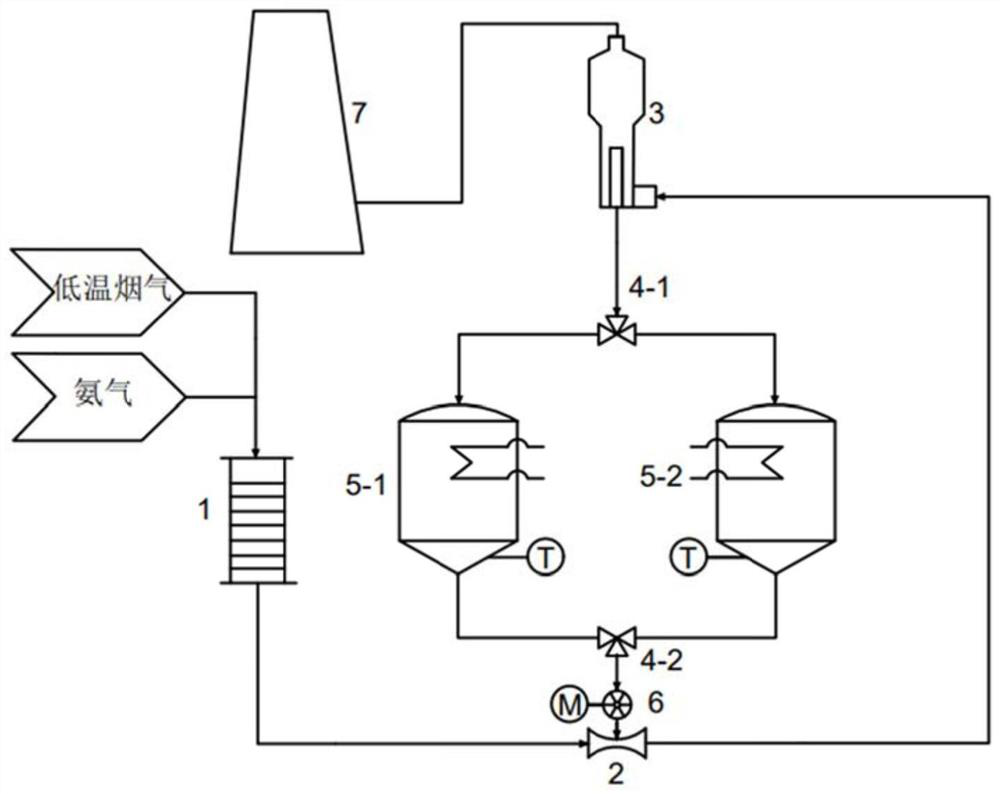

[0072] In a sintering unit of a 3000t / d sintering ore ironworks plant, the flue gas volume is large and unstable, and each ton of sintering ore produced can produce about 1500-3 000m3 3 flue gas volume, the fluctuation range of flue gas volume can reach 30%; affected by sintering raw materials, the composition of sintering flue gas is complex, except for SO 2 and NO x In addition, it also contains HF, HCI, iron-containing dust and heavy metals, etc.; the boiler operating load changes greatly, the exhaust gas temperature is low, and the flue gas temperature fluctuates at 130-280 °C. According to the method of the present invention, adopt NH 3 -SCR rotation control strengthens the denitrification device, purifies the low-temperature flue gas treated by the electrostatic precipitator and desulfurization tower, and realizes the removal of nitrogen oxides in the flue gas. At present, the small test and pilot test have been completed.

[0073] Material properties and related param...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap