Forging method for 1Mn18Cr18N nonmagnetic retaining ring of turbo-generator

A 1mn18cr18n, steam turbine generator technology, applied in the field of non-magnetic retaining ring forging of steam turbine generator 1Mn18Cr18N, can solve the problems of easy cracking of billets, affecting the quality of finished products, residual cracks in the forging process, etc., to achieve good grain size, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] This embodiment provides a method for forging a turbogenerator 1Mn18Cr18N non-magnetic retaining ring, including the following steps:

[0042] S1. Before forging, the billet is heated in three stages, the maximum heating temperature is 1180°C, and the holding time is 9-12h; the specific parameters of the three stage heating can refer to the specific parameters in the prior art mentioned in the above background technology parameters, so I won’t go into details here.

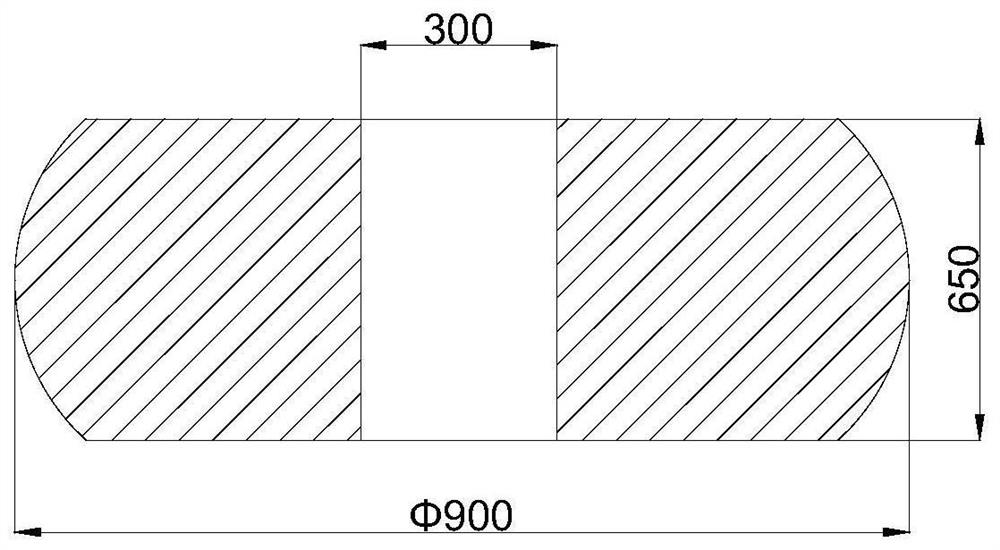

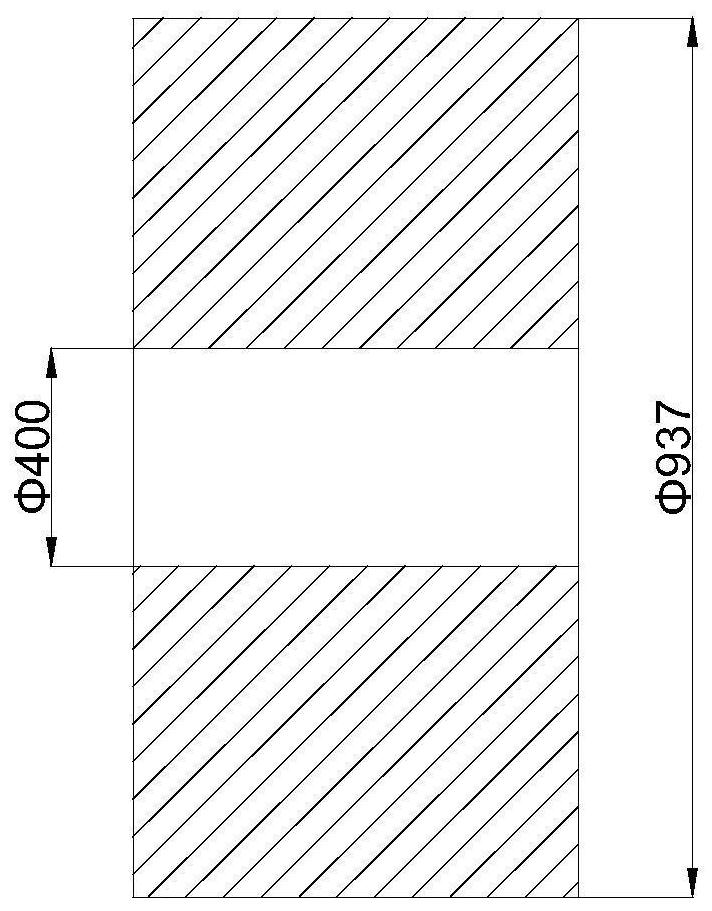

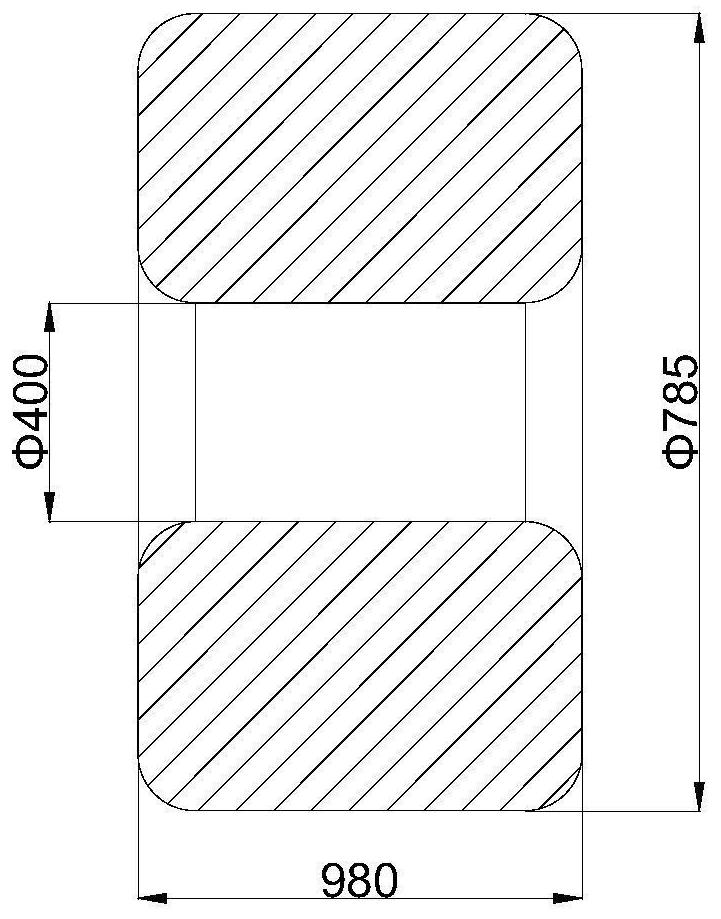

[0043] It should be noted that before heating the billet, the surface of the billet should be polished and scabs removed. In order to facilitate understanding of the forging method of this embodiment, this embodiment is described by forging an original billet with a diameter of φ600 mm and a height of 1320 mm.

[0044] S2. Forging, divided into six fires, including:

[0045] The first firing: Upsetting and punching the billet after heating and heat preservation in step S1, and returning the upsetting and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com