Investment casting mold core

A technology of investment casting and core, which is applied to casting equipment, molds, cores, etc., can solve problems such as the effect of product surface smoothness, and achieve the effect of reducing redundant parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

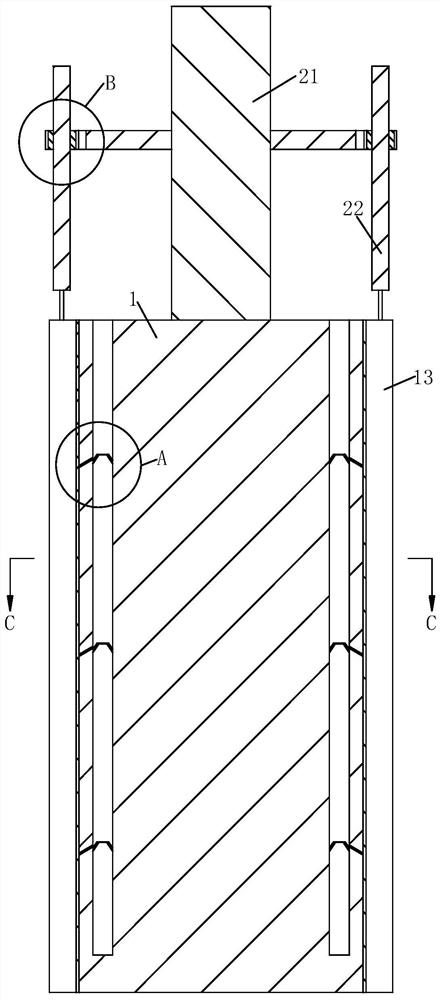

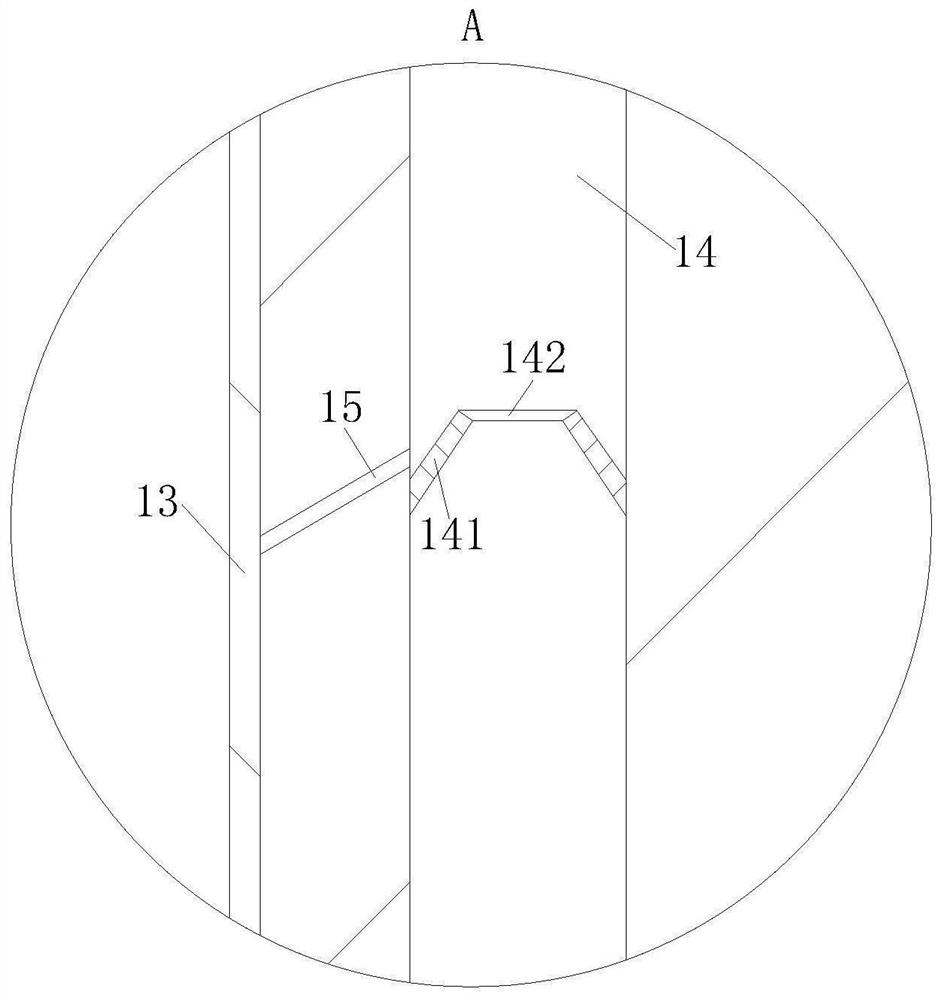

[0037] As a specific embodiment of the present invention, a No. 2 slot 14 is vertically arranged inside the core body 1 near the empty pipe 13, and a number of No. 3 slots 15 are arranged inside the core body 1. The size of the No. 1 slot 15 is smaller than the No. 2 slot 14 , and the No. 3 slot 15 communicates the No. 2 slot 14 with the No. 1 slot 12 .

[0038] During work, No. 2 slot 14 is vertically arranged inside the core body 1 and close to the empty pipe 13. The No. 2 slot 14 is evenly arranged around the center of the core body 1, and each empty pipe 13 corresponds to a No. 2 slot 14. No. groove 14 is equipped with an oily release agent inside; core body 1 is provided with several No. 3 grooves 15, the size of No. 3 groove 15 is smaller than No. 2 groove 14, and No. 3 groove 15 connects No. 2 groove 14 and No. 12 connected; that is, the oil-based release agent in the second groove 14 flows along the third groove 15 to the first groove 12 under the rotation of the empty...

specific Embodiment approach

[0039] As a specific embodiment of the present invention, the No. 3 groove 15 is arranged obliquely relative to the horizontal direction.

[0040] During work, the No. 3 groove 15 is inclined relative to the horizontal direction, and this setting makes the oily release agent in the No. 2 groove 14 more likely to flow into the No. 3 groove 15. Compared with the horizontal setting of the No. The oily release agent first flows into the No. 3 groove 15, and then cooperates with the rotation of the empty pipe 13 to smear more oily release agent on the side wall outer surface of the empty pipe 13; thus the normal performance of the device function is guaranteed.

[0041] As a specific embodiment of the present invention, several baffles 141 are uniformly arranged inside the No. 2 groove 14 , and the middle part of the baffles 141 is bent upwards and has a through hole 142 .

[0042] During work, the inside of No. 2 slot 14 is evenly provided with several baffle plates 141, and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com