Assembly method of multi-stage oil cylinder

An assembly method and oil cylinder technology, which are applied in the field of oil cylinder assembly, can solve problems such as unqualified cleanliness, iron filings generated by friction at the bottom of an inner hole of a cylinder bottom of a secondary cylinder, and iron filings generated by friction at the bottom of an inner hole of a secondary cylinder block. , to achieve the effect of good assembly quality, cleanliness assurance, and scientific design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

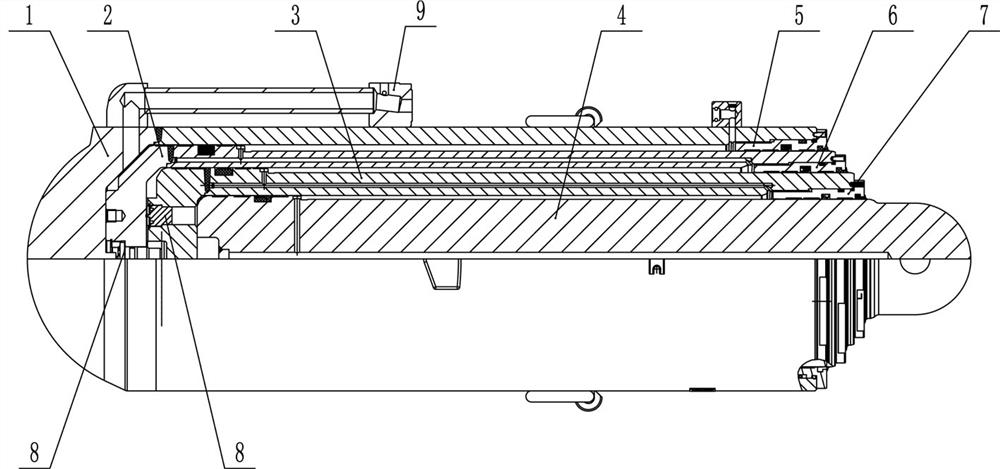

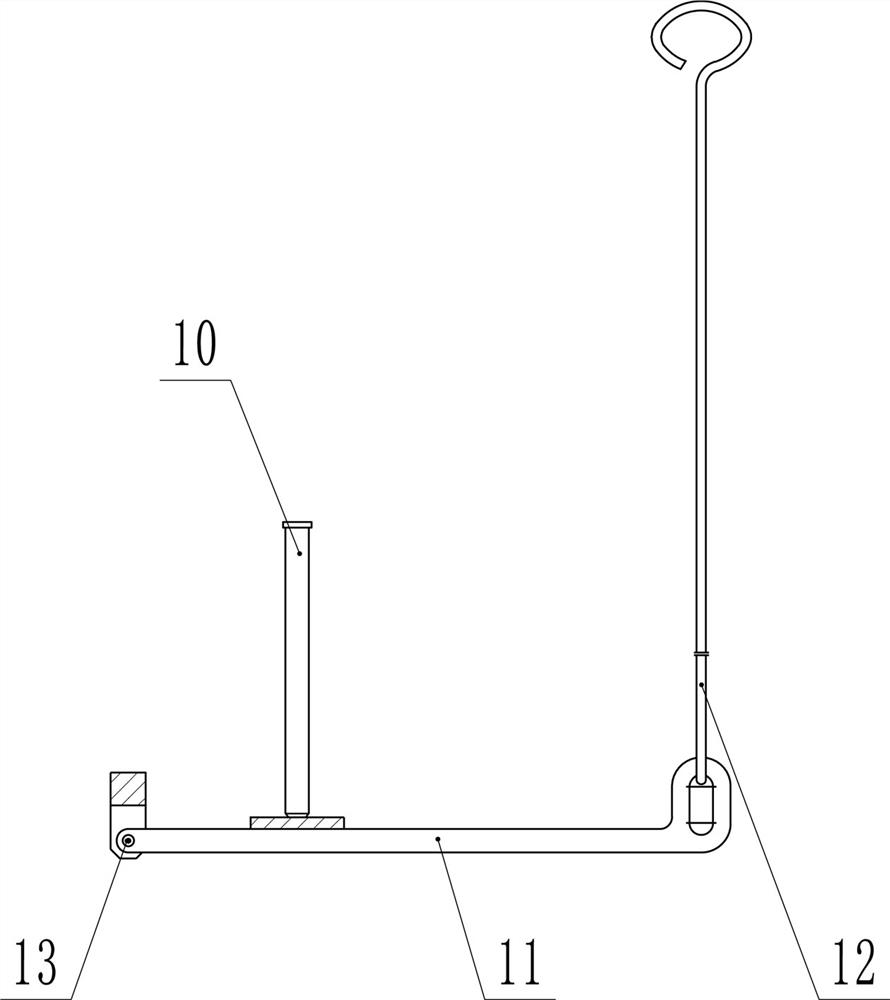

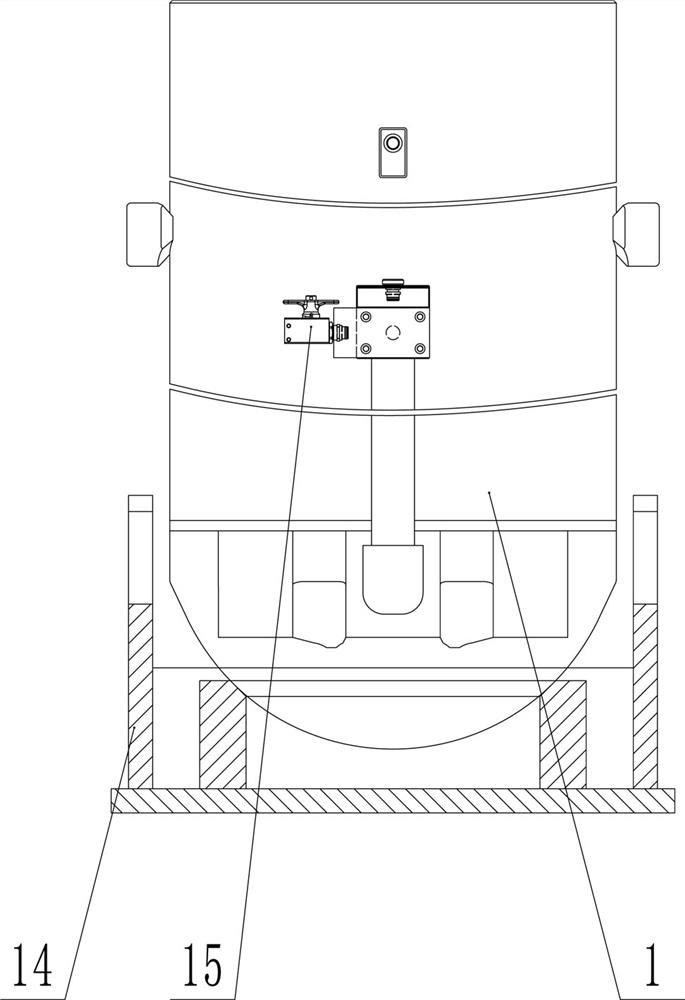

[0026] Such as Figure 1-4 As shown in the figure, an assembly method of a multi-stage oil cylinder regards the telescopic components in the cylinders of each level as a whole, and the lower-level telescopic components are directly sleeved in the upper-level cylinder. The assembly method starts from the innermost telescopic component , and assemble the cylinder blocks of all levels outward in turn, including the following cycle steps:

[0027] Step (a), place the upper cylinder block vertically with the opening facing upwards, and clamp the upper cylinder block from the outside;

[0028] Step (b), vertically drop the lower-level telescopic assembly into the upper-level cylinder. During the falling process, by controlling the connection between the inner hole of the upper-level cylinder and the outside air, the bottom end of the lower-lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com