Visual experiment device

An experimental device and inner cavity technology, which is applied in the field of visual experimental devices, can solve the problems of large area and complicated requirements of the experimental device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

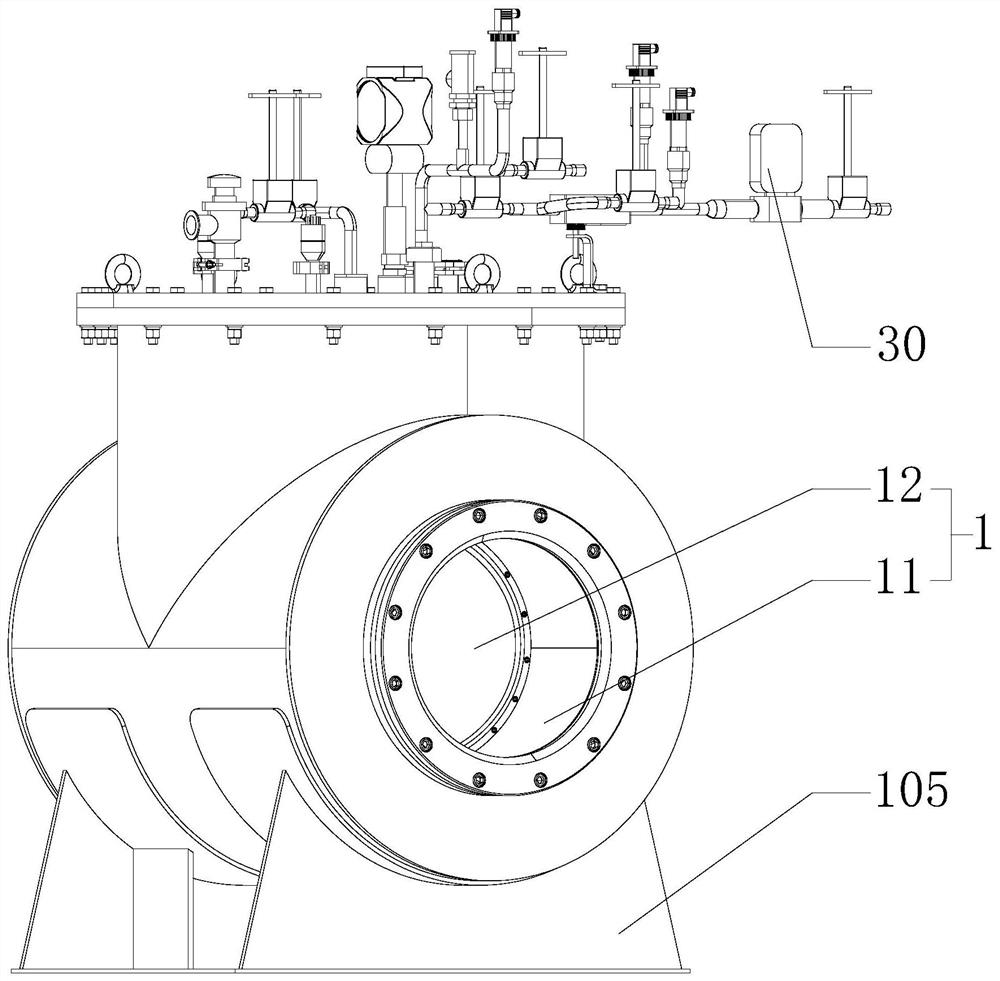

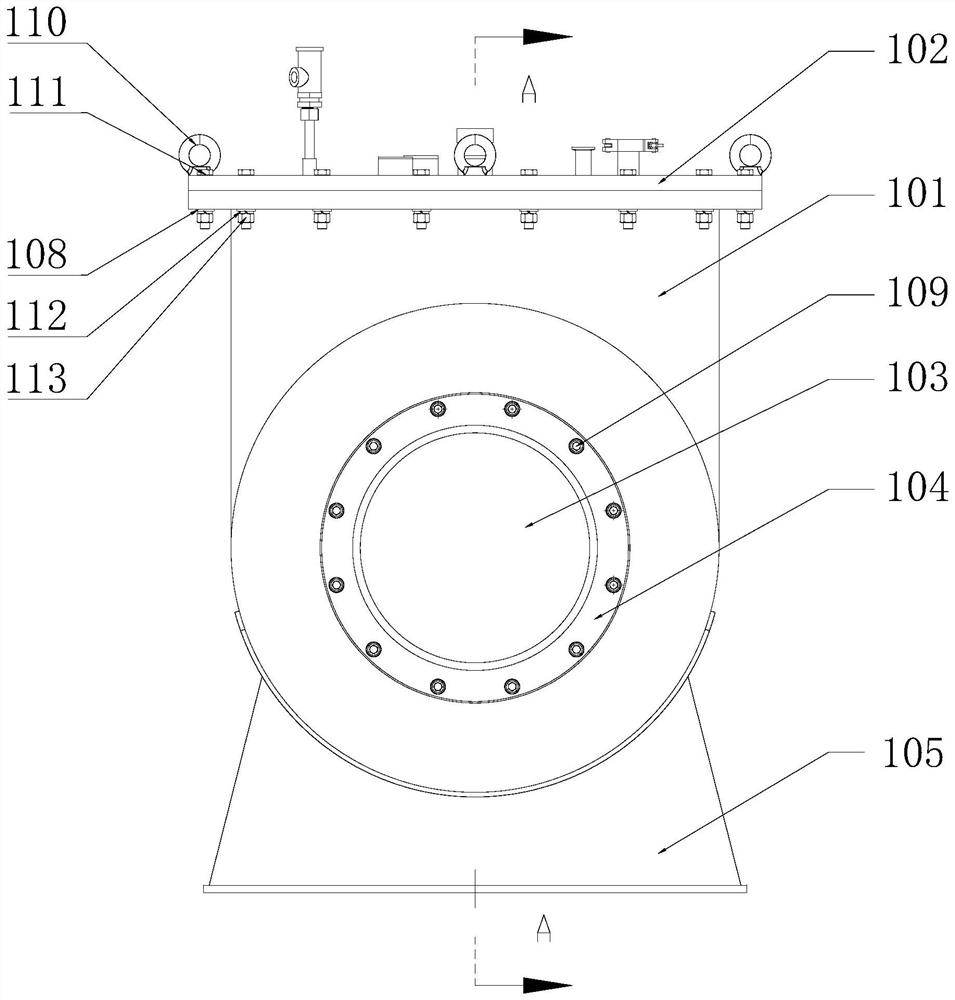

Method used

Image

Examples

experiment example 1

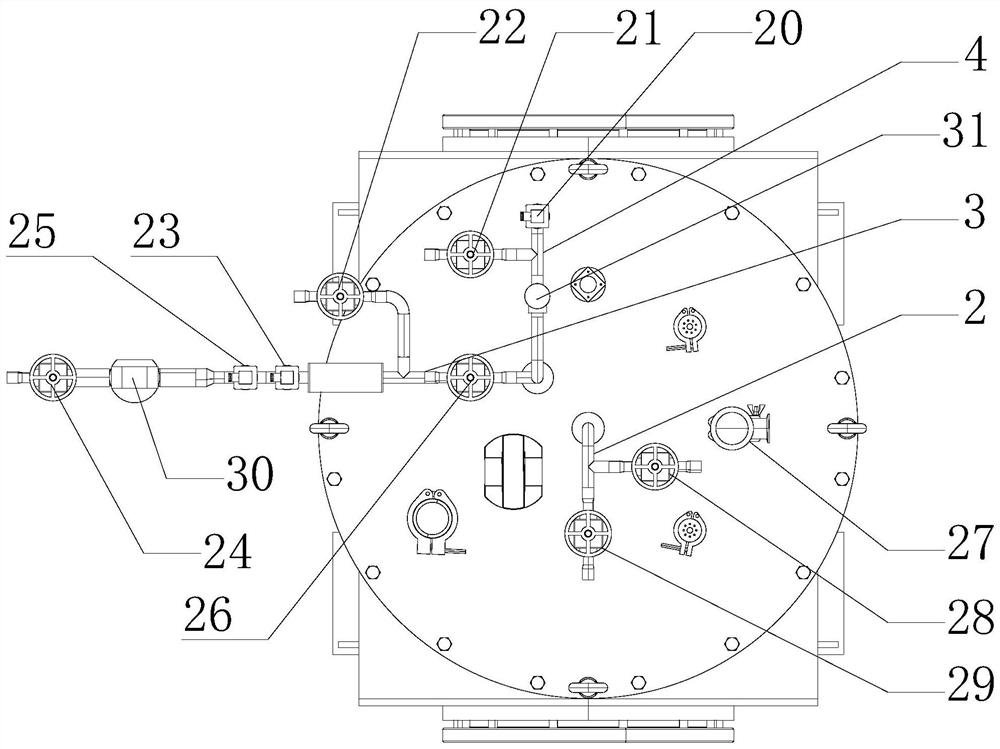

[0065] When conducting liquid nitrogen evaporation demonstration experiments, the following steps can be followed:

[0066] First, the molecular pump set is connected to the vacuum baffle valve 27 through the bellows to vacuumize the interlayer of the cavity;

[0067] Check the opening and closing status of each valve before filling liquid nitrogen. The third stop valve 29 of the liquid inlet line 2 and the second stop valve 21 of the exhaust line 4 are in the open state, and the other valves are closed; they are connected by corrugated hoses. The interface of the liquid nitrogen tank is connected to the interface of the liquid inlet pipeline 2, and the outlet valve of the liquid nitrogen tank is opened to inject liquid into the inner cavity cylinder 201; The liquid nitrogen in the inner cavity cylinder 201 will undergo a violent phase change and vaporize, and it will be exhausted violently after the exhaust valve. Be careful of low temperature frostbite; wait until the liquid...

experiment example 2

[0070] When performing the static evaporation rate test of the gas cylinder, the gas cylinder to be tested is connected to the 22 pipelines of the fourth shut-off valve through a metal hose, and the pipeline is turned on and heated to the required power. The temperature, pressure and flow data collected by the host computer can be Calculate the static evaporation rate.

experiment example 3

[0072] When used as a time measurement system, the gas cylinder to be tested is connected to the pipeline at the fourth stop valve 22 through a metal hose, the fourth stop valve 22 and the fifth stop valve 24 are opened, and after the gas evaporates to a certain pressure, the safety valve 31 It will take off to release the pressure, and the recorded take-off time of the safety valve 31 is the required measurement time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com