Preparation method and device of tin/carbon nanotube composite material

A carbon nanotube, composite material technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of difficult removal of impurities and complex processes, achieve simple equipment, ensure dispersibility, The effect of enhancing bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

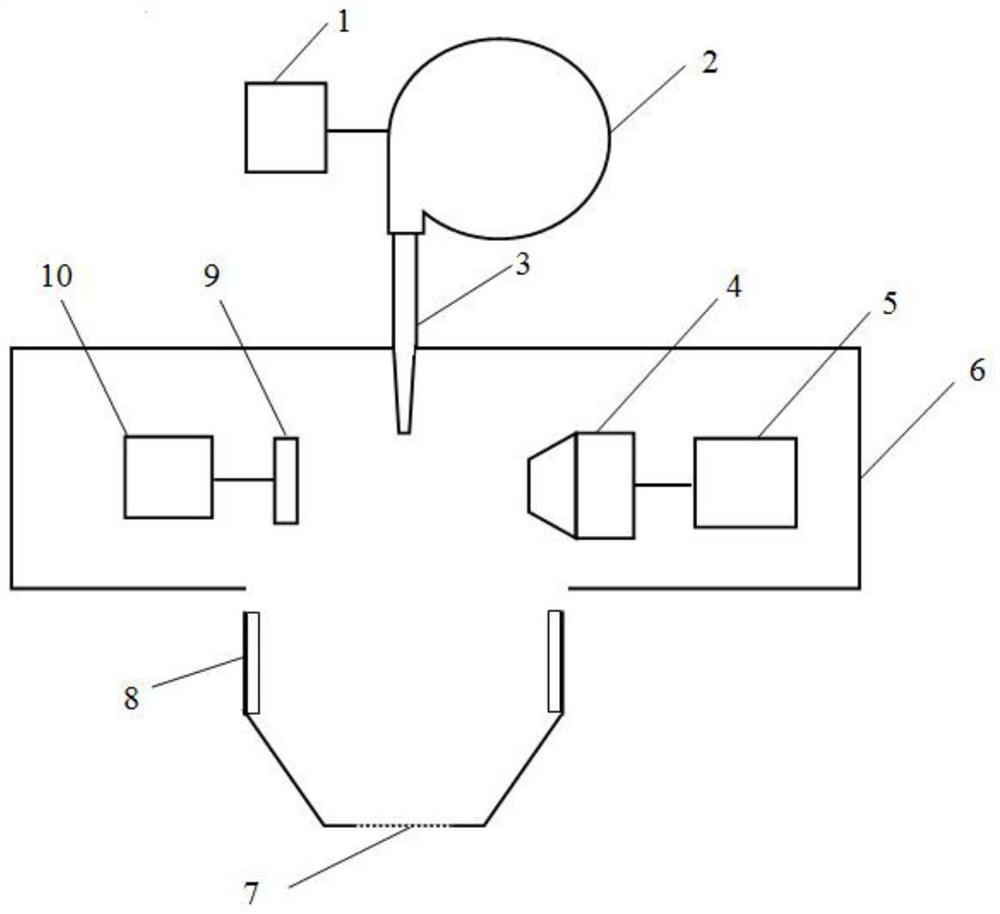

[0027] Such as figure 1 As shown, the preparation device of the present invention is mainly composed of a blower power supply 1, an electric heating blower 2, a gas diversion pipeline 3, a gas-phase dispersed mist generating device 4, a gas-phase dispersed mist generating device power supply 5, a sealing box 6, and a mesh ventilation plate 7 , An electrostatic adsorption collecting plate 8, an electric heating device 9, and a power supply 10 for the electric heating device. When in use, turn on the electric heating device power supply 10 power supply of the electric heating device 9 and the gas-phase dispersed mist generating device power supply 5 of the gas-phase dispersed mist generating device 4 to obtain tin vapor and carbon nanotube dispersed mist respectively, and realize the tin vapor by adjusting the two power supply parameters Control of fog concentration with carbon nanotube dispersion.

[0028] Turn on the blower power supply 1 of the electric heating blower 2 to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com