A kind of flexible electrochromic device and preparation method thereof

An electrochromic layer and chromogenic technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of complex process and device thickness reduction, and achieve uniform color change, device thickness reduction, and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention also provides a method for preparing a flexible electrochromic device, comprising the following steps:

[0030] Step 1: Clean the diaphragm;

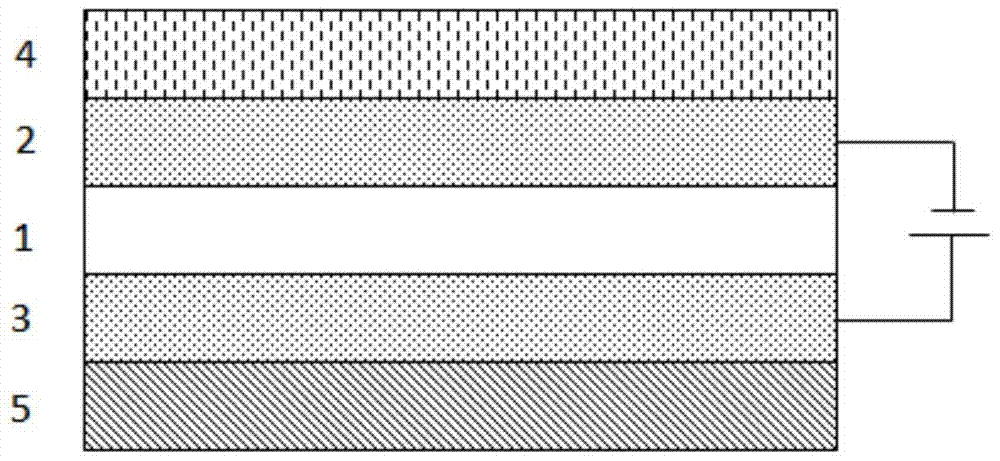

[0031] Step 2: Depositing the first conductive metal film 2 and the second conductive metal film 3 on both sides of the diaphragm;

[0032] Step 3: Deposit an electrochromic layer 4 and an ion storage layer 5 on the surfaces of the first metal conductive film 2 and the second metal conductive film 3 obtained in step 2, respectively;

[0033] Step 4: Coating the electrolyte on the surface of the ion storage layer to fully infiltrate and penetrate the diaphragm;

[0034] Step 5: Leading out the first metal conductive film 2 and the second metal conductive film 3 by using conductive metal foil as upper and lower electrodes, and then encapsulating with a transparent thin film to obtain an electrochromic device.

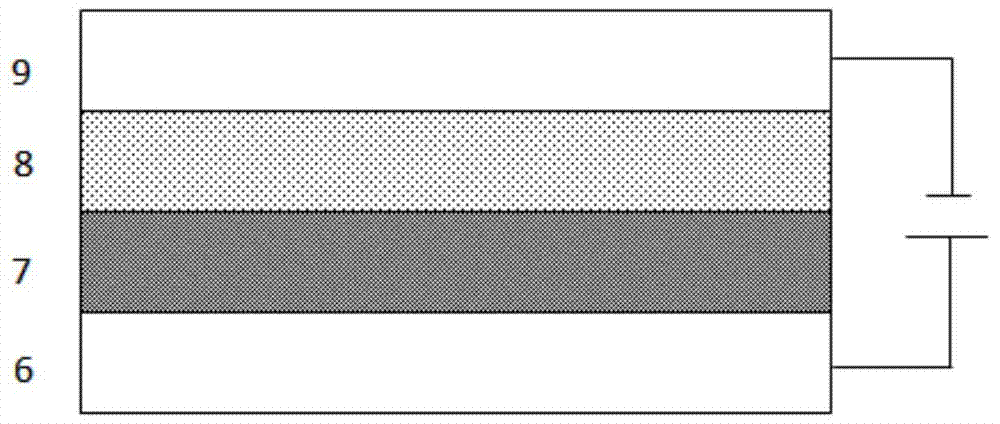

[0035] Further, the diaphragm 1 described in step 1 is a flexible membrane such as a polyethersulf...

Embodiment 1

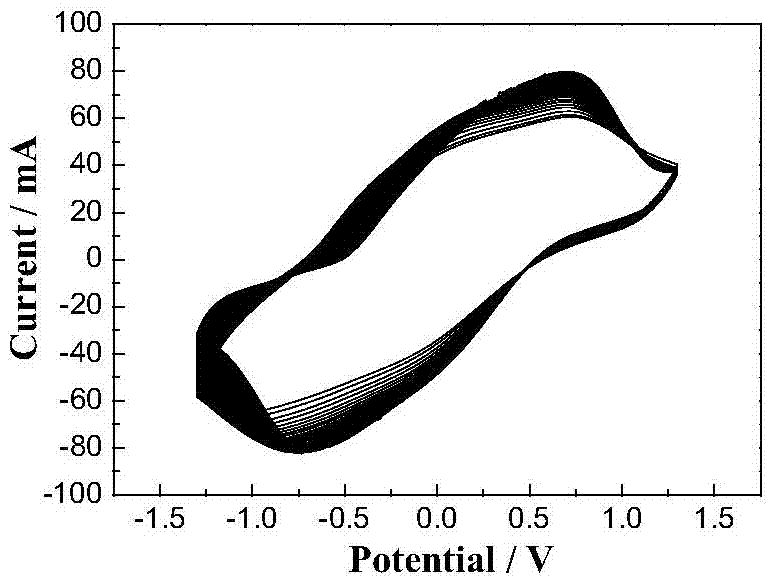

[0038] In this example, a nylon filter membrane (thickness 0.25 μm, pore size 0.1 μm) is used as the diaphragm material. The nylon filter membrane has good ion and electrolyte permeability, strong corrosion resistance, high strength, and certain flexibility. The electrolyte can still maintain good flatness after soaking and drying, and the surface of the filter membrane can be firmly combined with the evaporated gold particles. The materials of the electrochromic layer and the ion storage layer in this example are both polyaniline (PANI), because PANI has rich color changes, fast response speed, and good film-forming uniformity.

[0039] A flexible electrochromic device comprises a nylon filter membrane, gold films deposited on both sides of the nylon filter membrane, PANI electrochromic layers and PANI ion storage layers deposited on the surfaces of both gold films.

[0040] A method for preparing a flexible electrochromic device, specifically comprising the following steps: ...

Embodiment 2

[0048] The difference between this example and Example 1 is that the polyaniline film is deposited on both sides of the nylon filter membrane gold membrane by chemical oxidation polymerization. , and ultrasonically obtain a uniform solution; put the nylon filter membrane (5×5m) with gold film on both sides obtained in step 2 into the solution, and stir for 2h; dissolve 2g of ammonium persulfate (APS) in 60mL of deionized water , to obtain an ammonium persulfate solution; the prepared ammonium persulfate solution was slowly added dropwise to the above-mentioned solution with a filter membrane, and continued to stir for 12 hours; after the reaction was completed, the prepared polyaniline film was rinsed with deionized water to remove The oligomers on the surface of the film were left to dry for later use.

[0049] The flexible electrochromic device provided by the present invention is based on a flexible diaphragm with a conductive metal film evaporated on both sides. Electroche...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com