Speed reduction motor for cleaning machine

A technology for geared motors and washing machines, applied in the field of washing machines, which can solve the problems of geared motors corrosion, inability to effectively prevent splashed water from entering the interior, damage, etc., and achieve the effects of stable rotation or stop, stable and smooth sliding, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

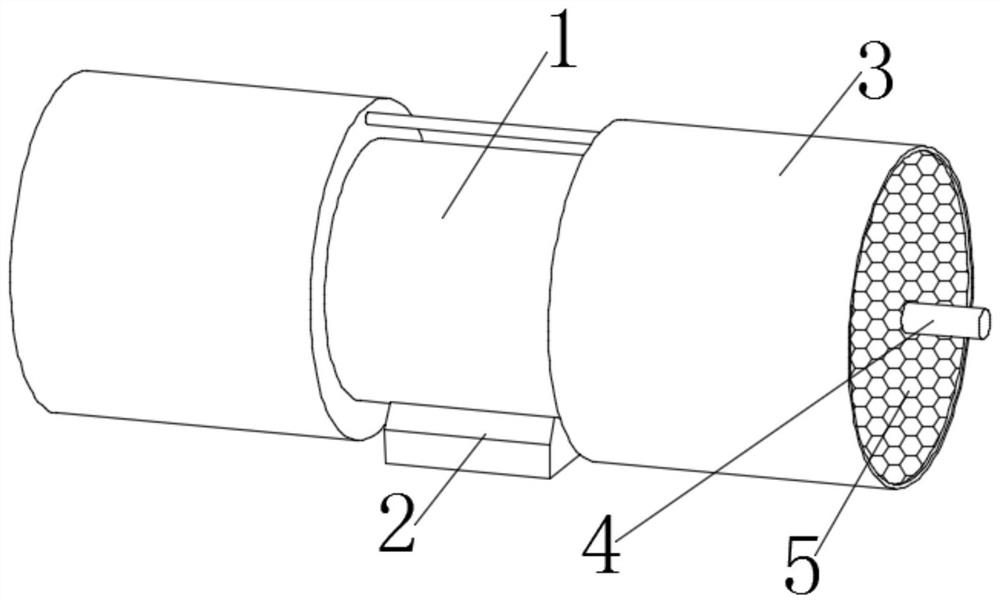

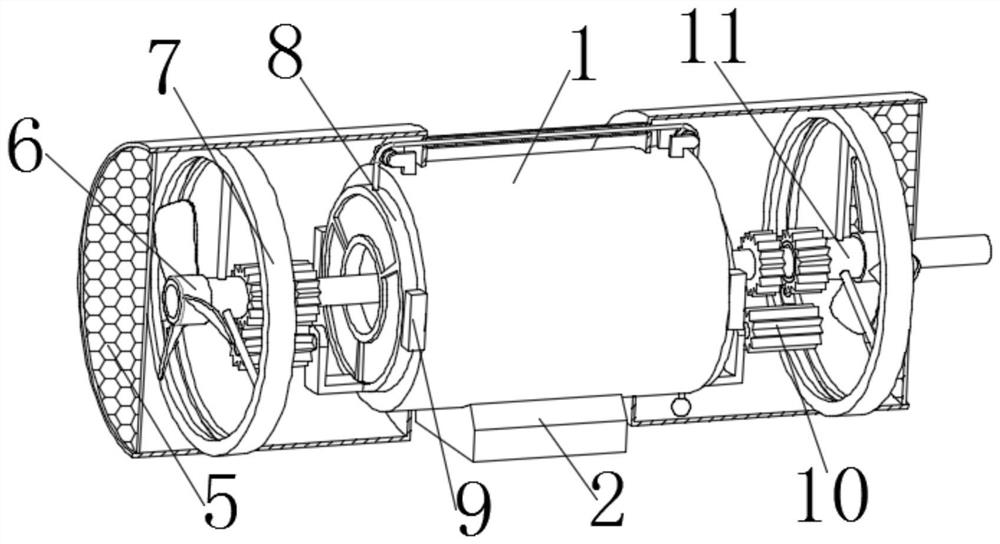

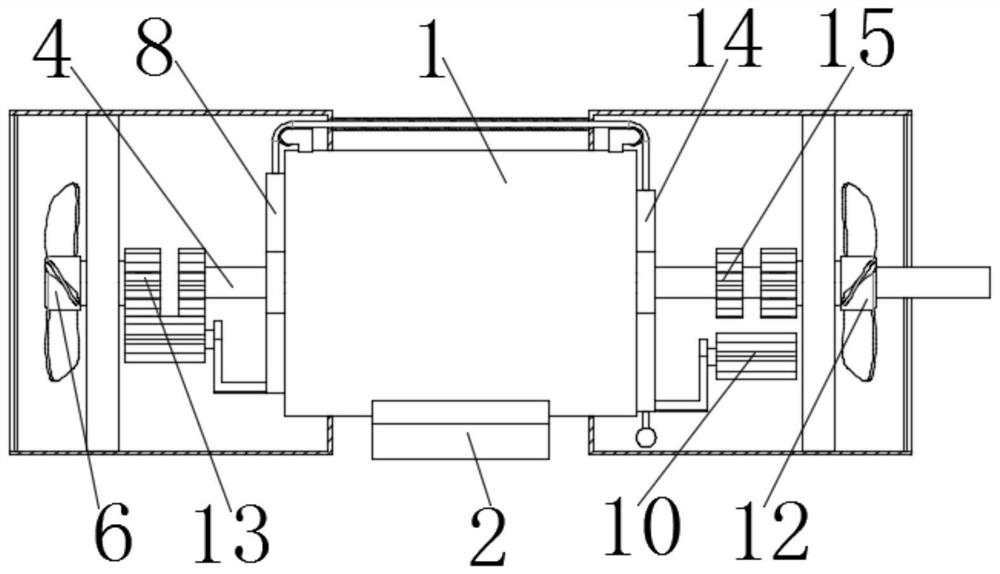

[0039] Example: Reference Figure 1-8 The shown a geared motor for washing machines comprises a geared motor body 1, a motor base 2 mounted on the bottom of the geared motor body 1, a rotating main shaft 4 mounted on the geared motor body 1, and both ends of the geared motor body 1 are There are a plurality of evenly arranged ventilation holes 29, and the first fixing frame 8 and the second fixing frame 14 are respectively installed at both ends of the geared motor body 1, and a counterweight 28 is installed on the second fixing frame 14, and the first fixing frame 8 and the second fixed mount 14 are equipped with a plurality of absorbent cotton 16, the first fixed mount 8 and the second fixed mount 14 are connected by a connecting unit, the first fixed mount 8 and the second fixed mount 14 are respectively connected with a plurality of ventilation The holes 29 are in contact with each other, and the geared motor body 1 is equipped with a blowing assembly for two-way blowing. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com