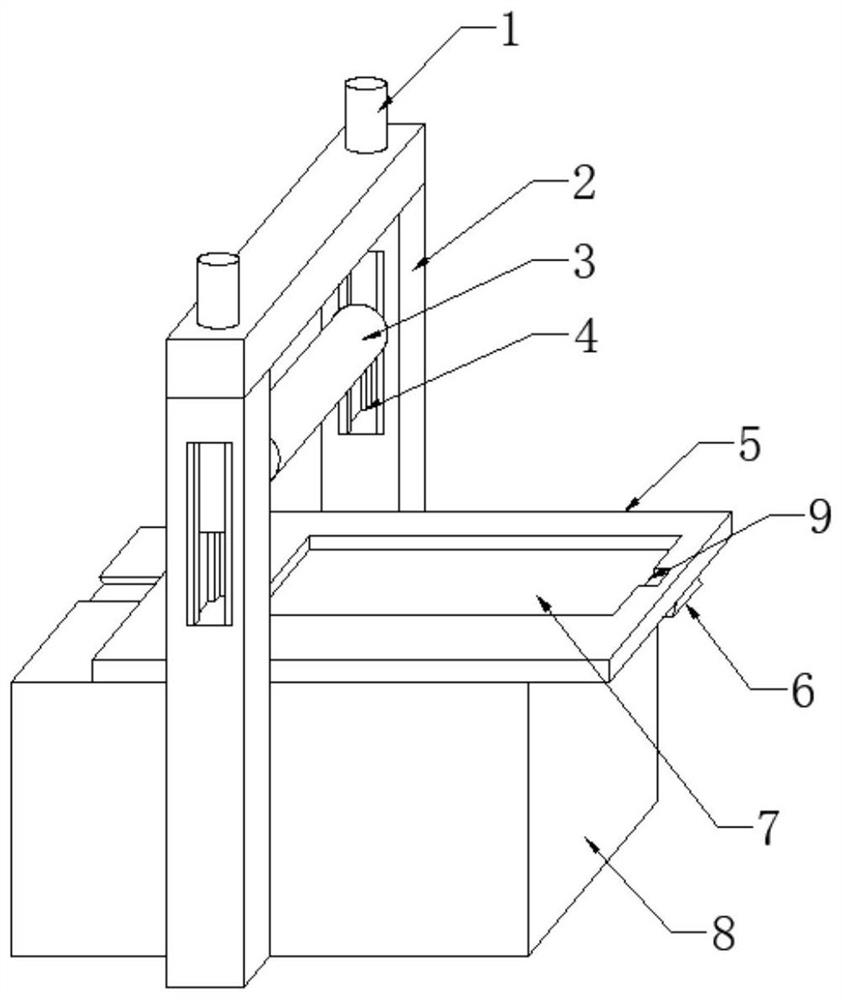

Fiberboard hydraulic machining device

A hydraulic processing and fiberboard technology, which is applied to wood processing appliances, household components, flat products, etc., can solve the problem of uneven application of force, achieve uniform force, and solve the effect of reducing the performance of the board

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

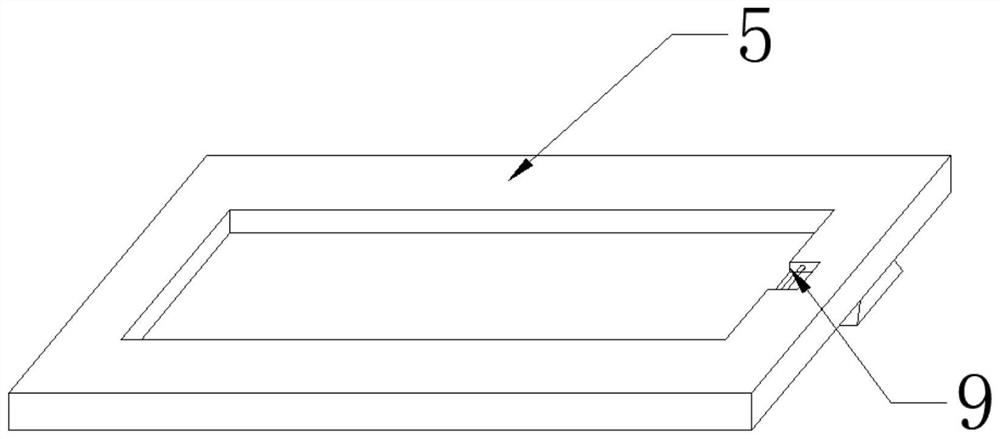

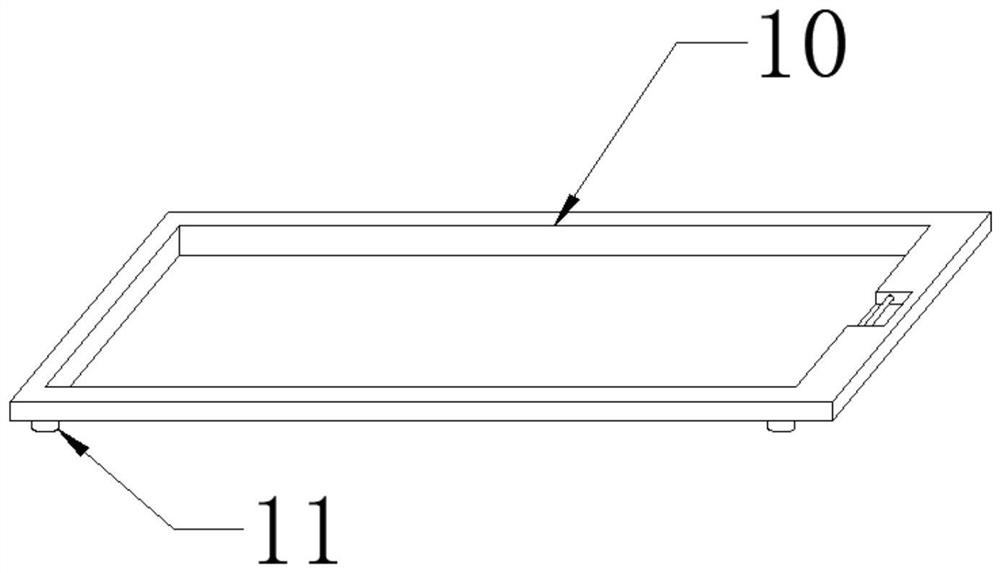

[0023] Specific implementation method: It is necessary to select the inner frame 10 of different specifications according to the needs, then clamp the limit protrusion 11 with the groove, then place the plate to be extruded inside the inner frame 10, start the drive motor and The electric push rod 1, the electric push rod 1 drives the pressure roller 3 to move downward, and then achieves the purpose of controlling the vertical movement of the pressure roller 3, and cooperates with the sliding processing table 5 to perform repeated movements on the upper end surface of the cabinet body 8, Furthermore, the extrusion of the fiberboard on the surface of the pressure roller 3 is achieved. This design makes the force on each position of the fiberboard uniform during the extrusion process, which solves the problem of the performance degradation of the board caused by the uneven force on each position of the traditional fiberboard. The driving motor drives the sliding processing table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com