Composite carbon fiber stranded inhaul cable

A technology of composite carbon fiber and carbon fiber, applied in the cable field, can solve the problem of not overcoming the non-shear resistance of pure carbon fiber cable, and achieve the effect of good economic effect, easy engineering application and promotion, and strong competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

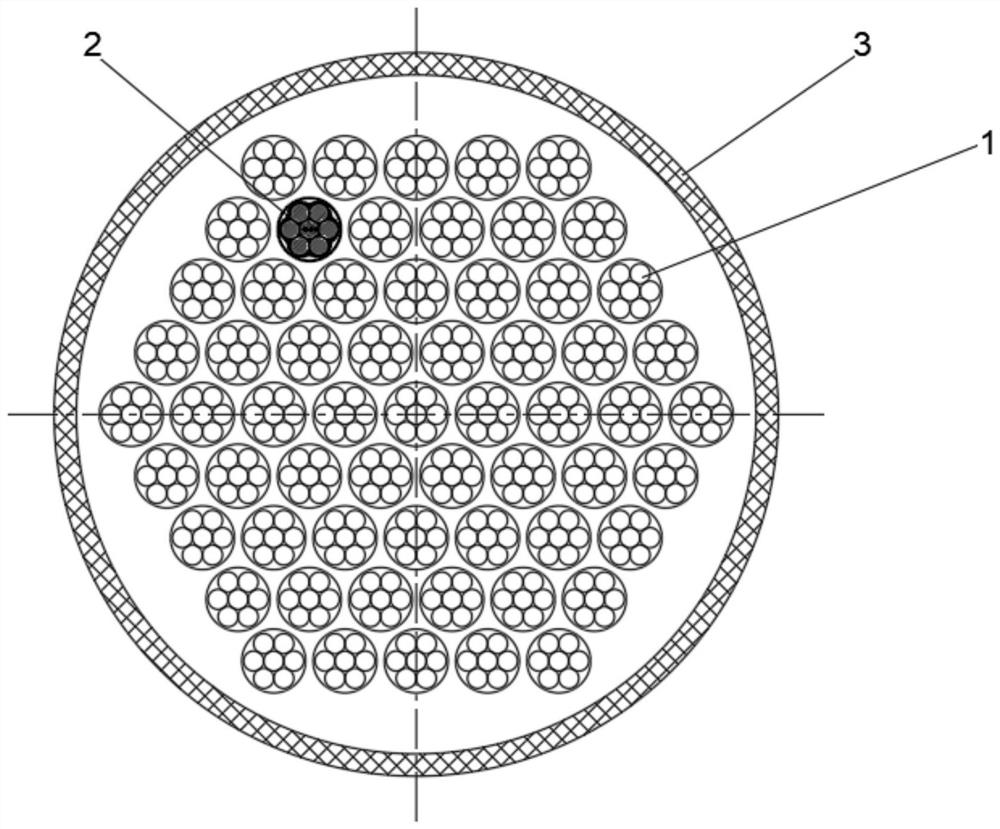

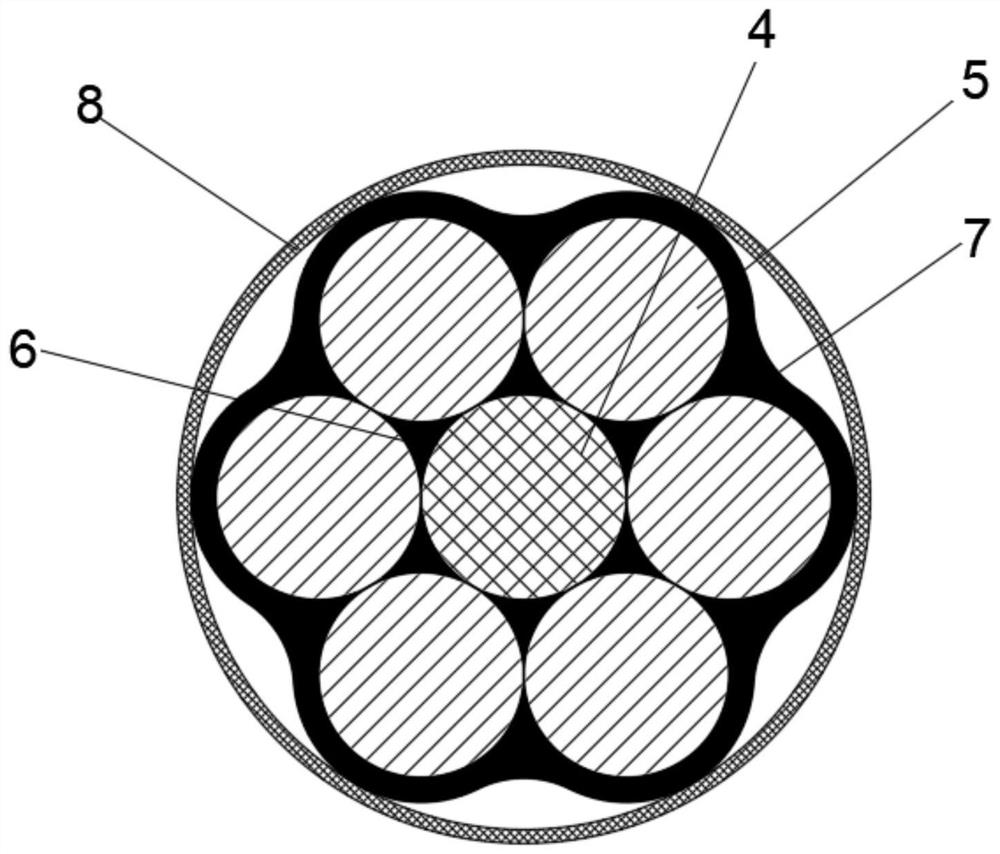

[0029] Such as Figure 1-Figure 2 As shown, the invention provides a composite carbon fiber stranded cable,

[0030] It includes a stranded wire body and a large sheath 3. The large sheath 3 is arranged on the outer surface of the stranded wire body for protecting the stranded wire body. The stranded wire body includes a steel strand 1, a composite carbon fiber strand 2. The composite carbon fiber strand 2 includes edge steel wire 5, carbon fiber central wire 4, epoxy coating, and PE sleeve 8, the steel wire and the carbon fiber central wire 4 are hinged together, and the PE sleeve 8 is set The outer surface of the composite carbon fiber strand 2 is used to protect the composite carbon fiber strand 2. The side steel wires 5 are arranged in six groups, and the six groups of side steel wires 5 are evenly wound and arranged on the center wire 4 of the carbon fiber. On the outer side wall, the epoxy coating includes a first epoxy coating 6 and a second epoxy coating 7, the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com