Column-supported-by-beam transfer beam with steel plate reinforced concrete shear walls arranged in adjacent spans

A steel plate concrete and steel plate shear wall technology, applied in the field of transfer beams, can solve problems such as insufficient shear resistance of steel concrete columns and sudden changes in bearing capacity, and achieve the effect of reducing impact and harmonizing building functions and structural systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

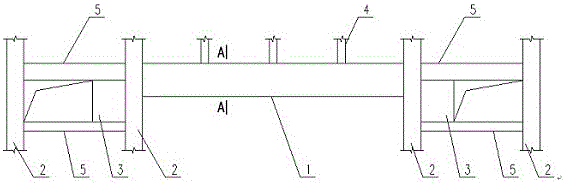

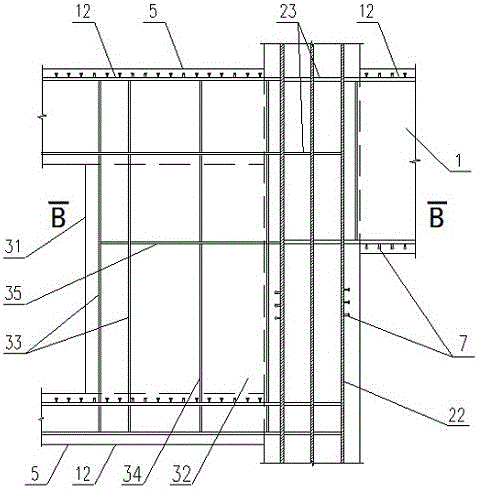

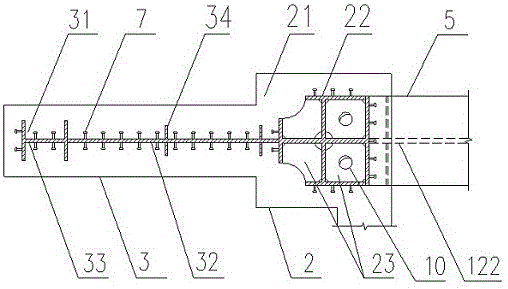

[0026] In the large-span structure of high-rise and super-high-rise buildings described in the present invention, a kind of adjacent span is provided with steel plate concrete shear wall beam supporting column conversion beam such as figure 1 As shown, there are steel concrete transfer beam 1, steel concrete column 2, steel plate concrete shear wall 3, square steel pipe concrete column 4 and steel concrete beam 5; described steel concrete conversion beam 1, steel concrete beam 5 are formed by Concrete beam 11, I-shaped steel beam 12, but its specific cross-sectional size and the spatial relationship of adjacent components are not the same; the steel concrete column 2 is composed of concrete column 21, cross-shaped steel frame 22, steel partition 23; The square steel pipe concrete column 4 is composed of a square steel pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com