Novel prefabricated concrete beam column joint and construction method thereof

A technology of prefabricated concrete and beam-column joints, which is applied in the direction of architecture and building construction, which can solve the problems of difficult assembly and construction, poor joint connection, poor shear resistance, etc., and achieves convenient installation, avoiding reinforcement, and good integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

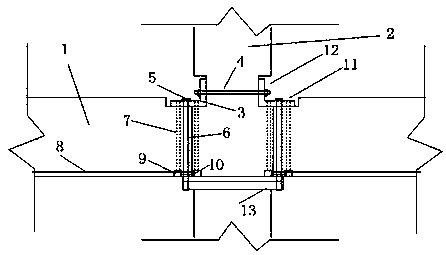

[0026] Such as Figure 1-7 As shown, a new type of precast concrete beam-column joint, the beam-column joint needs to prepare precast beam 1, precast column 2, angle steel 3, connecting bolt 5 and connecting box bolt 10.

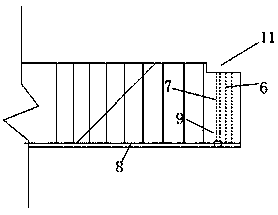

[0027] Such as figure 2 As shown, for the production of prefabricated beam 1, it is necessary to select and arrange the positions of pre-embedded through holes 6 and reserved grouting holes 7 at the beam end, and pre-embed the connection box 9 on the left according to the arrangement of longitudinal ribs 8 , to ensure that the longitudinal reinforcement 8 extends to the end of the beam, and a row of holes for passing through the bolts 10 of the connection box shall be reserved on the prefabricated beam 1 .

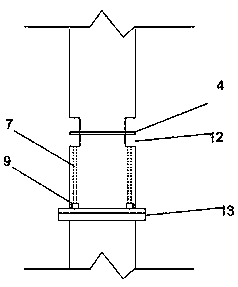

[0028] Such as image 3 and Figure 4 As shown, for the manufacture of the prefabricated column 2, the most important thing is to pre-embed the angle steel bolt 4 and the T-shaped steel 13. Embedding is an important step to ensure its shear resistan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com