Molten salt storage tank with leakage detection and thermal compensation device

A leak detection and thermal compensation technology, applied in the field of molten salt storage tanks, can solve the problems of molten salt storage tanks not working normally, leakage of molten salt storage tanks, slow project progress, etc., to reduce the time required for preheating and avoid pollution , the effect of improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

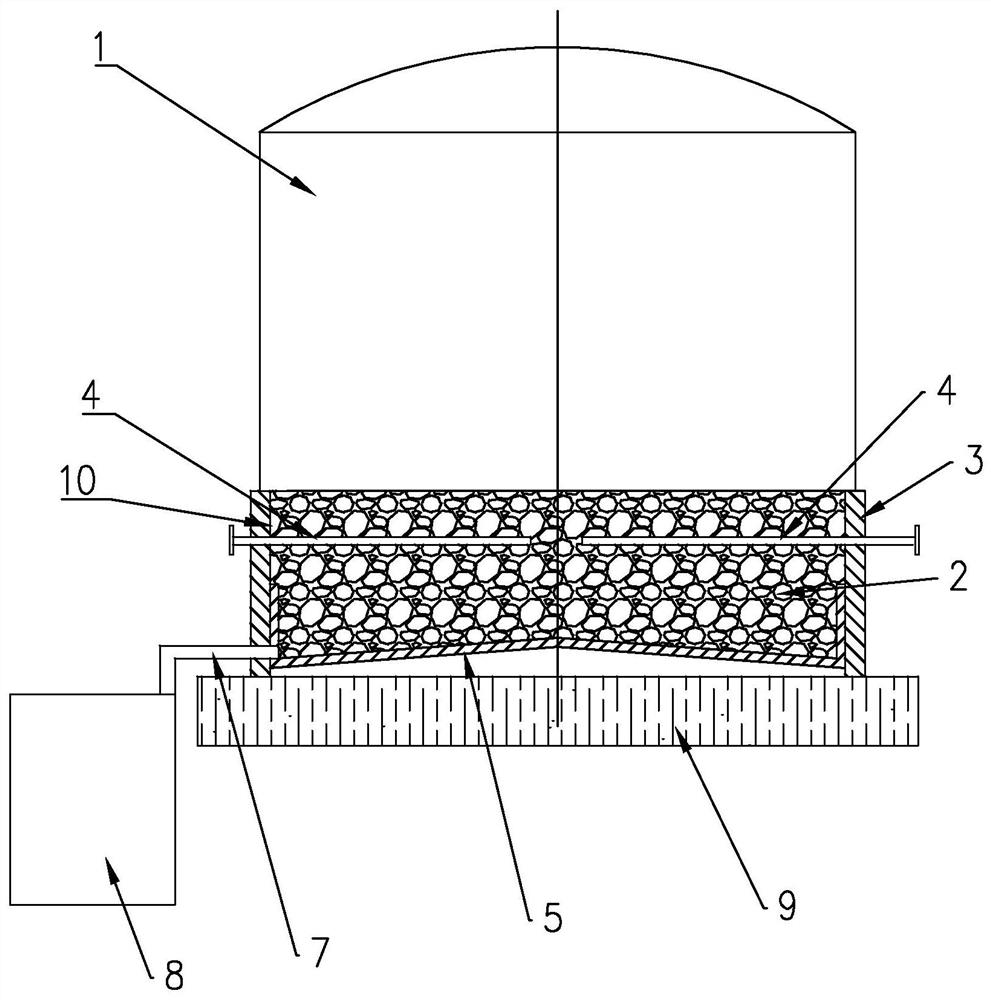

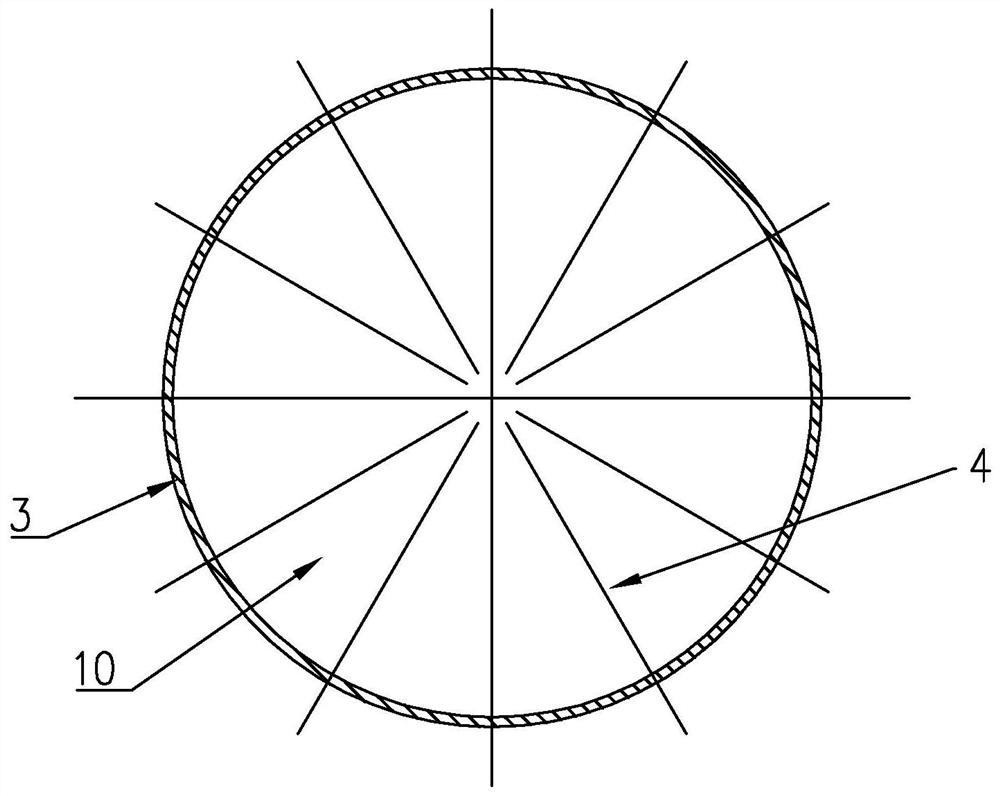

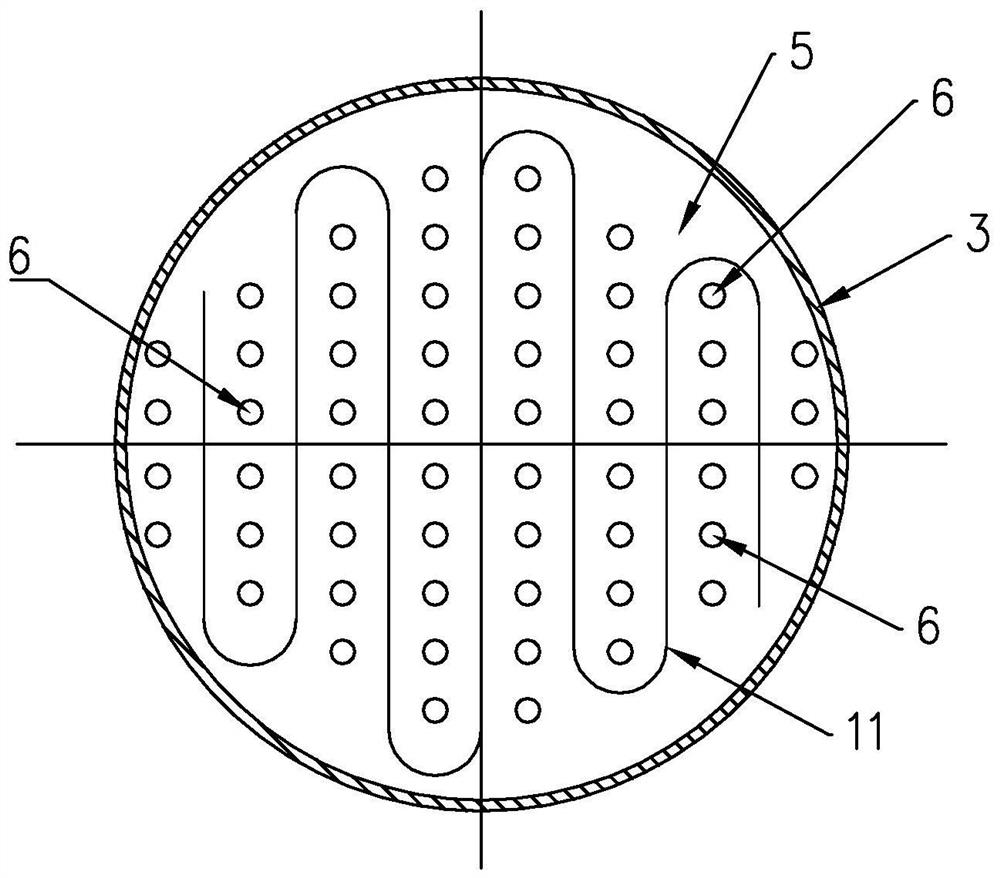

[0020] Such as figure 1 , figure 2 and image 3 As shown, the molten salt storage tank with a leak detection and thermal compensation device of the present invention includes a tank body 1, a sleeve 3 is provided below the tank body 1, and the top of the sleeve 3 is attached to the bottom plate of the tank body 1. The lower part of the sleeve 3 is provided with a leak detection bottom plate 5, the edge of the leak detection bottom plate 5 is fixedly connected with the inner wall of the sleeve 3, and the sleeve 3, the leak detection bottom plate 5 and the bottom plate of the tank body 1 form a chamber 10, the chamber The upper part of the chamber 10 is provided with more than one heating rod 4, the chamber 10 is filled with an insulating material layer 2, and the lower part of the chamber 10 communicates with the molten salt collection tank 8 through the salt discharge pipe 7;

[0021] The leak detection base plate 5 is provided with a plurality of thermocouples 6 for temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com