Finite element generation method, equipment and medium for three-dimensional stress of tie bar and dowel bar

A three-way stress and dowel rod technology is applied to the finite element generation of three-way stress of tie rods and dowel rods, computer equipment and a computer-readable storage medium field, which can solve the nonlinear contact problem and the convergence cannot be calculated. As a result, problems such as inability to accurately simulate cement slab tie rods and dowel rods, in-depth analysis of unfavorable cement pavement structure forces, etc., achieve the effect of easy in-depth analysis, high accuracy, and optimal design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

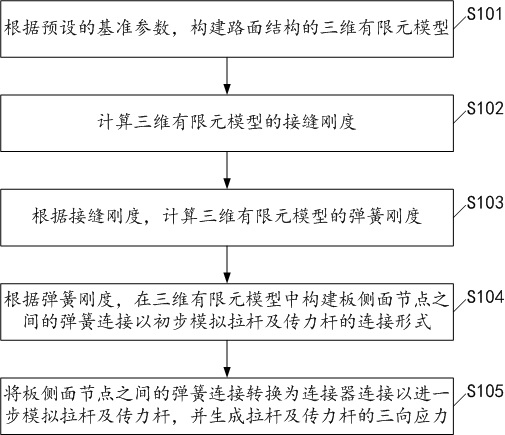

[0034] see figure 1 , figure 1 The flow chart of an embodiment of the finite element generation method of the three-dimensional stress of the tie rod and the dowel bar of the present invention is shown, which includes:

[0035] S101. Construct a three-dimensional finite element model of the pavement structure according to preset reference parameters.

[0036] It should be noted that the benchmark parameters include structural layer parameters and material parameters, and the specific benchmark parameters are shown in Table 1:

[0037]

[0038] Correspondingly, the benchmark parameters can be preset according to the actual situation, so as to construct a three-dimensional finite element model for the benchmark parameters.

[0039] S102, calculating the joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com