Hub motor with high torque volume ratio

A technology of hub motor and volume ratio, which is applied in the direction of electrical components, electromechanical devices, electric components, etc. It can solve the problems of uneven distribution of radial force, difficulty in reducing weight, and inability of the output shaft to penetrate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0029] Before the present invention is described in detail, it should be noted that in the following description, similar components are denoted by the same numerals.

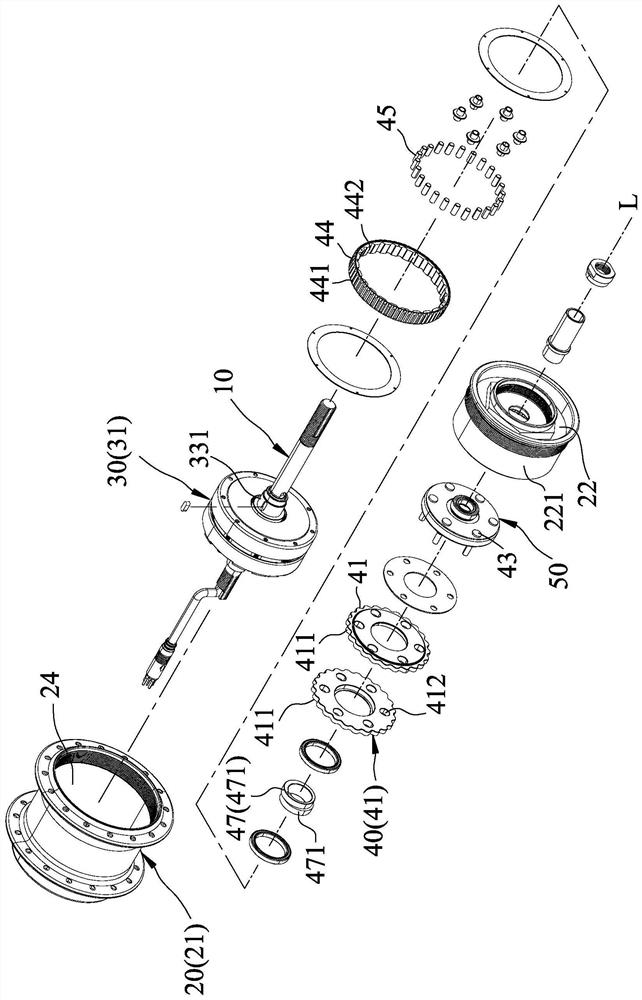

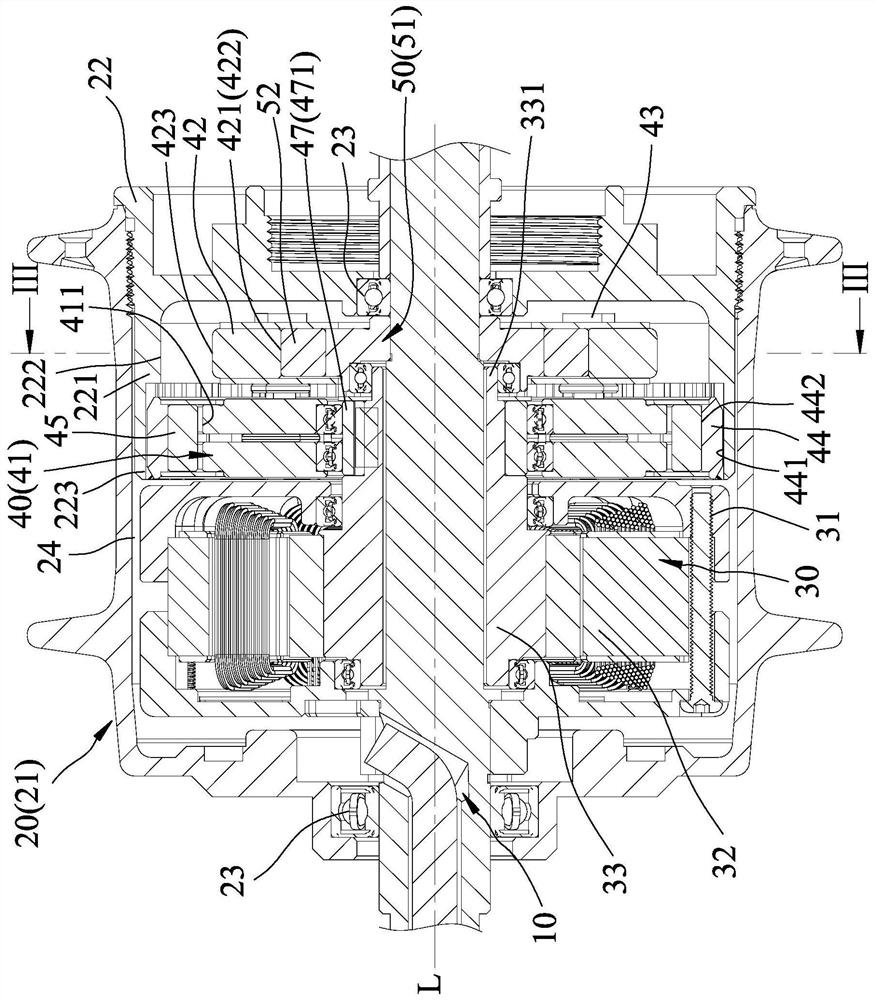

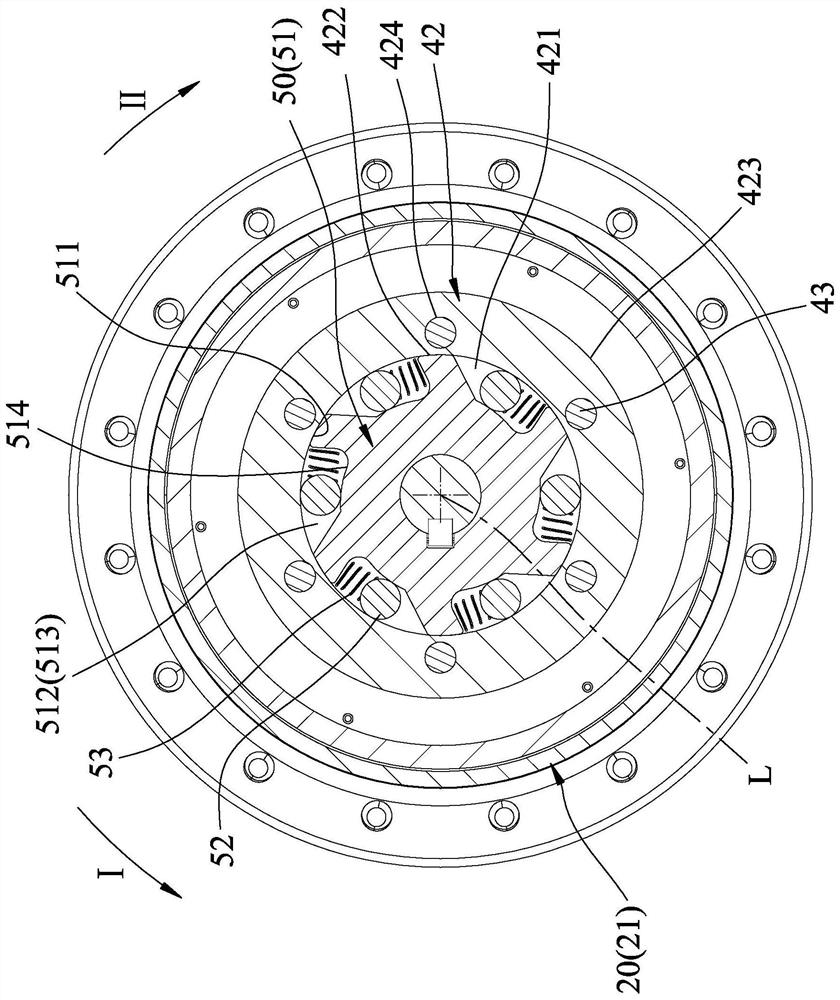

[0030] refer to Figure 1 to Figure 3 , The first embodiment of the hub motor with a high torque-to-volume ratio of the present invention includes a shaft member 10 , a hub shell 20 , a motor unit 30 , a cycloid reduction unit 40 and a one-way clutch unit 50 .

[0031] The shaft 10 extends along an axis L. As shown in FIG.

[0032] The hub shell 20 is supported by the shaft 10 and can rotate around the shaft 10, and the hub shell 20 has a body 21, an end cover 22 screwed on one side of the body 21, and two sleeves The bearing 23 between the body 21 , the end cover 22 and the shaft 10 . The body 21 and the end cover 22 jointly define an accommodating space 24, the end cover 22 has an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com