Rod progressive wave type ultrasonic electric machine

An ultrasonic motor, traveling wave technology, applied in the direction of generators/motors, electrical components, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., can solve problems such as small torque, complex structure, and limited application range , to achieve the effect of simple structure, small volume and large torque-to-volume ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

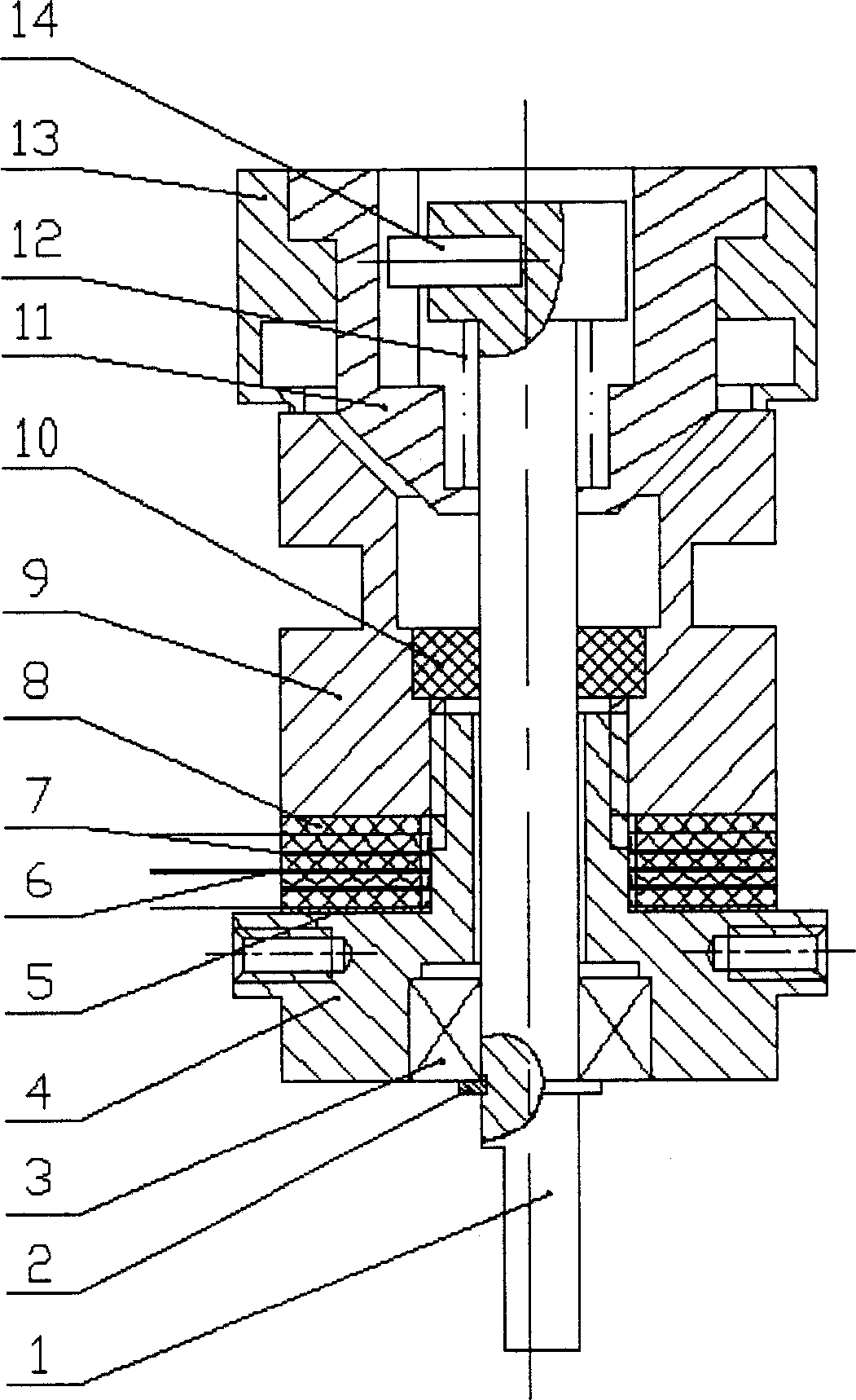

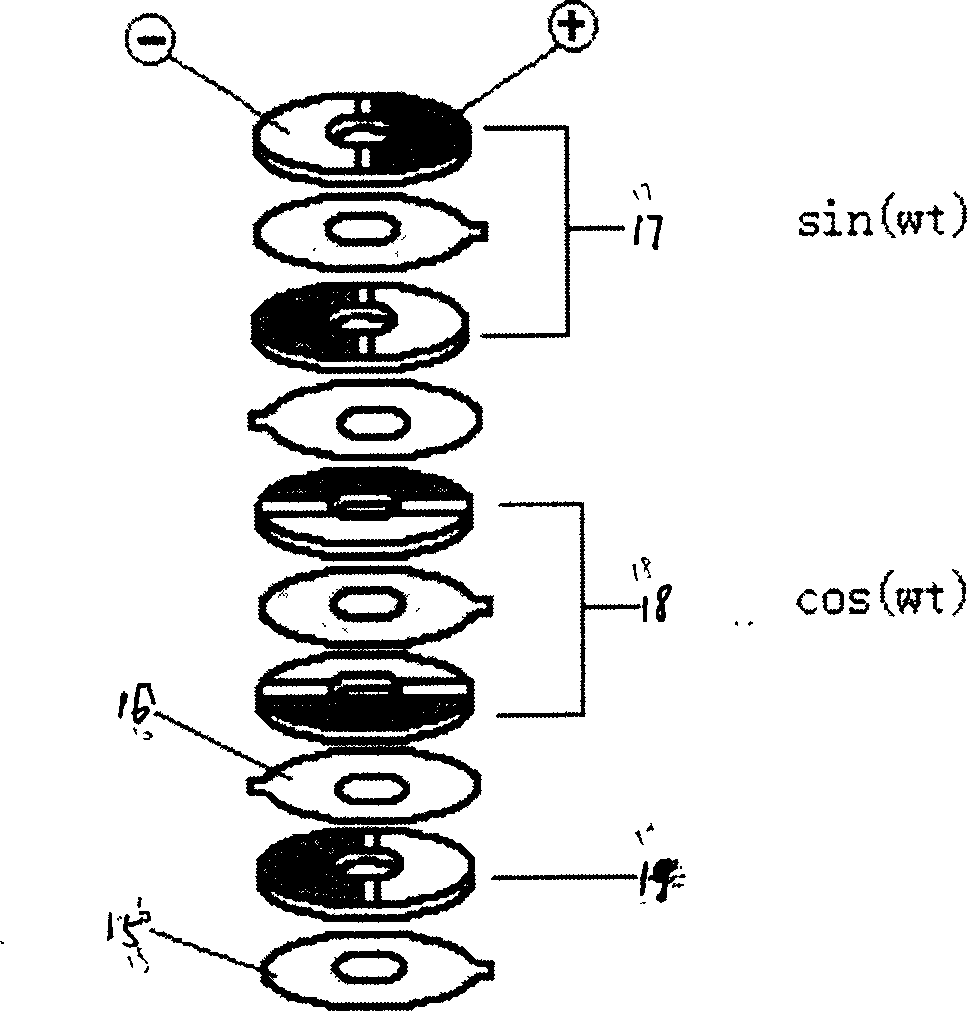

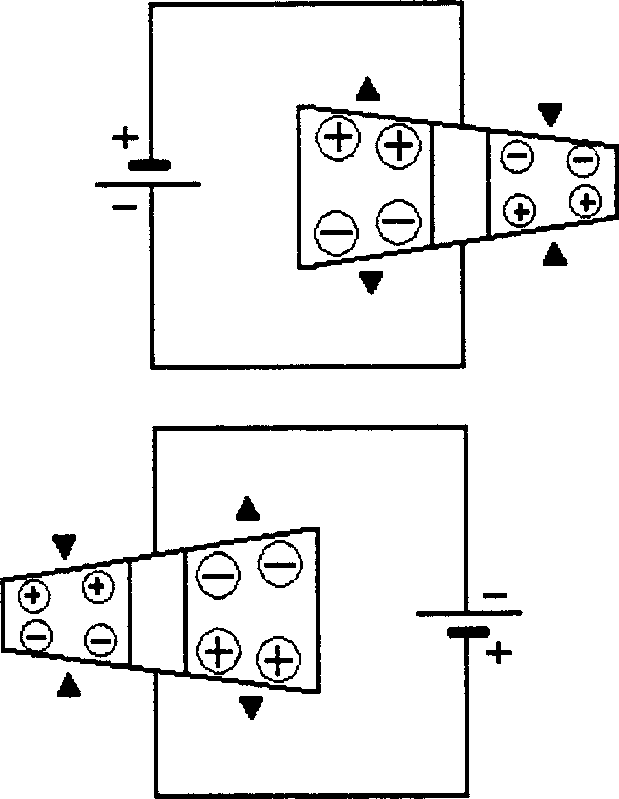

[0011] The invention is a novel ultrasonic motor developed based on the use of piezoelectric ceramic sheets to excite the first-order bending vibration of the Langevin vibrator. It is mainly composed of stator assembly, rotor assembly and output shaft. Fig. 1 is the specific structure schematic diagram of the present invention, as can be seen from the figure, the stator of motor is made of piezoelectric ceramic sheet group 8 (5 pieces in total) and electrode sheet group 7 (3 pieces in total) by lower counterweight block 4 and upper counterweight block 9 ) and 2 pieces of grounding piece group 6 (2 pieces in total), which are compressed by the screw on the lower weight 4 to form a Langevin vibrator. The lower counterweight 4 of the stator has an outer ring boss, and six threaded holes are arranged on the boss, in order to fix the protective cover (not shown in the structure diagram) and install the motor. There is a bearing hole in the lower counterweight 4, and the embedded r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com