Method for improving residual oil component distribution by using hydrogen donor under action of ultrasonic waves

A hydrogen-donating agent and ultrasonic technology, applied in the chemical industry, can solve the problems of high colloid and asphaltene content, achieve the effect of reducing component distribution, reducing content and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Step 1: Slowly heat 50 g of the residual oil to a fluid state, then add tetralin therein, stir to make it fully mixed, and the mass ratio of tetralin to the residual oil is 20%.

[0017] Step 2: Divide the uniformly mixed oil sample into several parts, and ultrasonicate the oil sample at different temperatures for 25 minutes under the condition of ultrasonic power of 50 W.

[0018] Step 3, take 1g from each ultrasonic oil sample to separate the four components, weigh the separated four components, and compare the mass changes of the four components with those of the untreated residual oil.

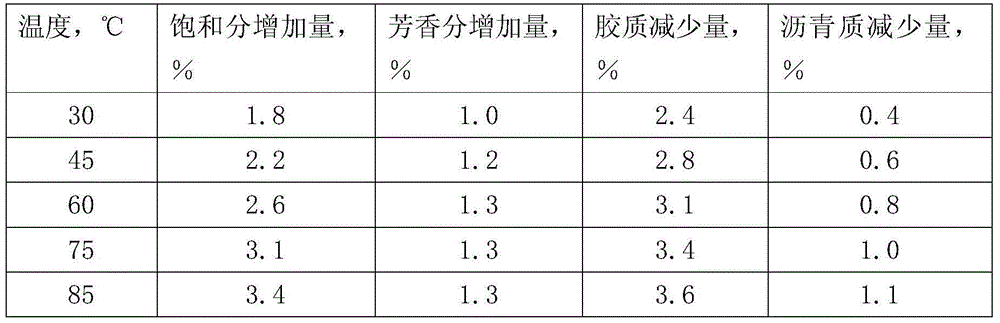

[0019] The amount of mass change of each component at different temperatures using the present invention is shown in Table 1.

Embodiment 2

[0021] Step 1: Slowly heat 50 g of the residual oil to a fluid state, then add tetralin therein, stir to make it fully mixed, and the mass ratio of tetralin to the residual oil is 20%.

[0022] Step 2: Divide the homogeneously mixed oil sample into several parts, and ultrasonicate the oil sample at different temperatures for 25 minutes under the condition of ultrasonic power of 200W.

[0023] Step 3: Take 1 g from the ultrasonicated oil sample to separate the four components, weigh the separated four components, and compare the mass changes of the four components with those of the untreated residual oil.

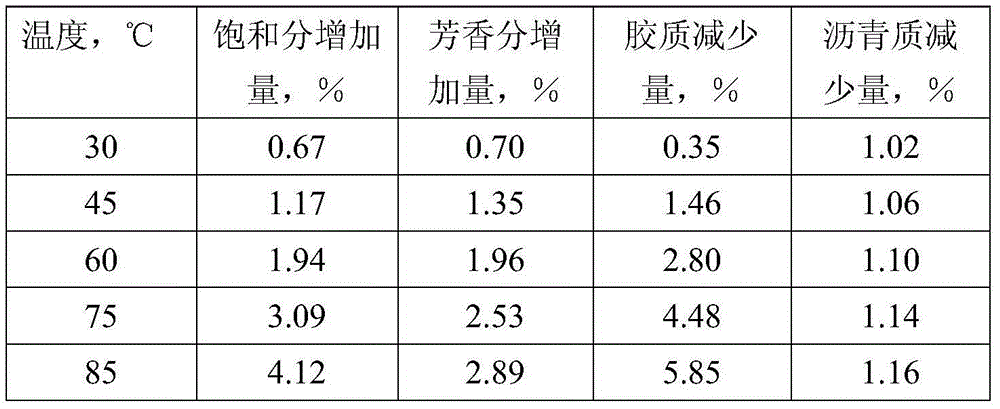

[0024] The amount of mass change of each component at different temperatures using the present invention is shown in Table 2.

Embodiment 3

[0026] Step 1: Slowly heat 50 g of residual oil to a fluid state, then add a straight-run diesel fraction to it, stir to make it fully mixed, and the mass ratio of the straight-run diesel fraction to the residual oil is 20%.

[0027] Step 2: Divide the mixed and uniform oil sample into several parts, and ultrasonicate the oil sample at different temperatures for 25 minutes under the condition of ultrasonic power of 50 W.

[0028] Step 3, take 1g from each ultrasonic oil sample to separate the four components, weigh the separated four components, and compare the mass changes of the four components with those of the untreated residual oil.

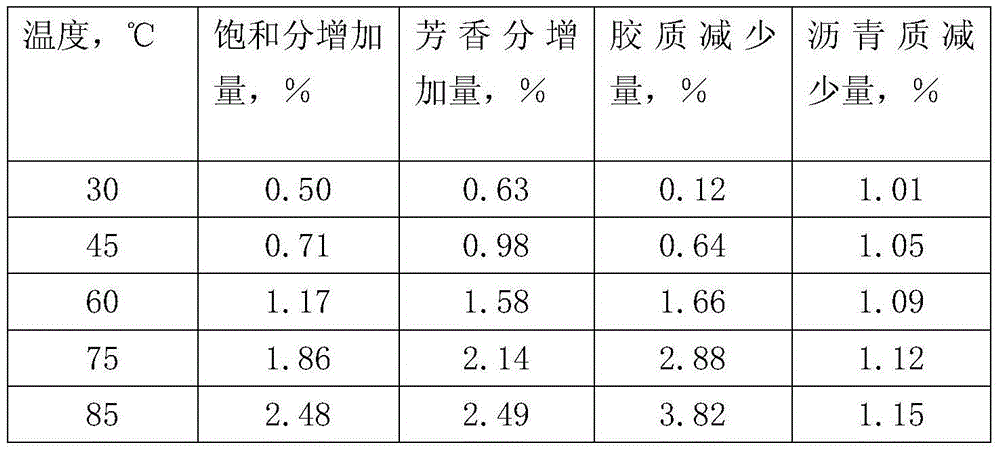

[0029] The amount of mass change of each component at different temperatures using the present invention is shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com