Special positioning disc for lead type electronic component reverse pasting machine

A technology of electronic components and anti-sticking machines, which is applied in the direction of electrical components, electrical components, and electrical components to assemble printed circuits. The effect of increasing working strength, avoiding mechanical jamming, and simplifying operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

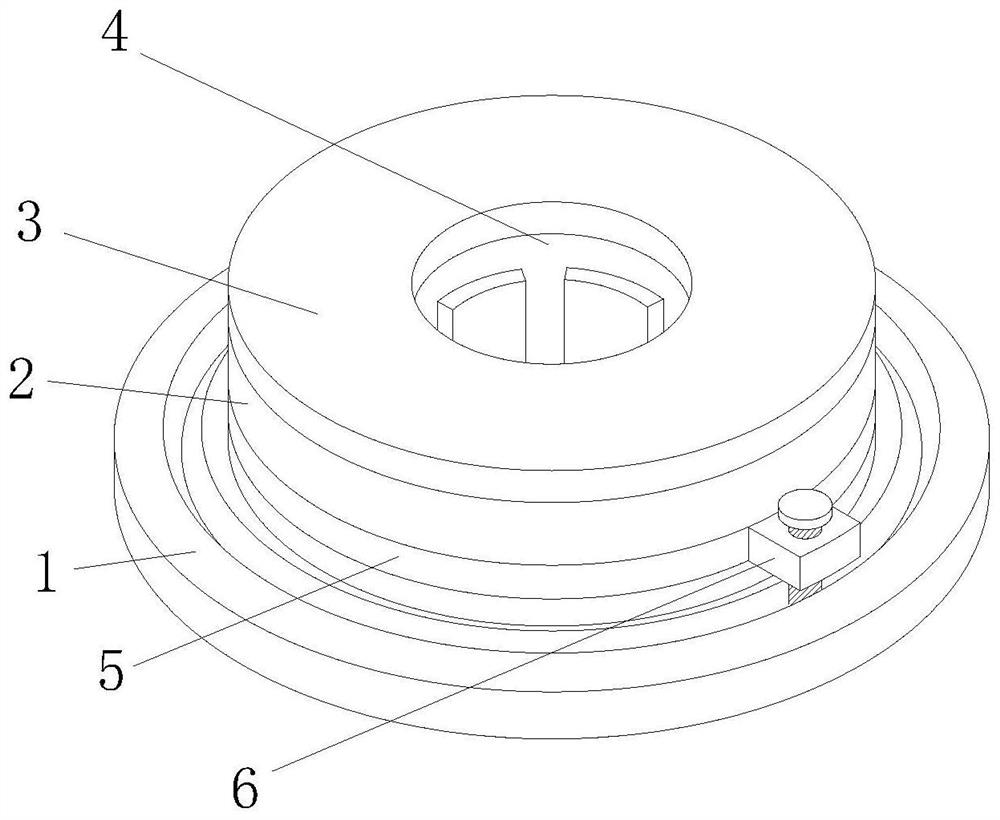

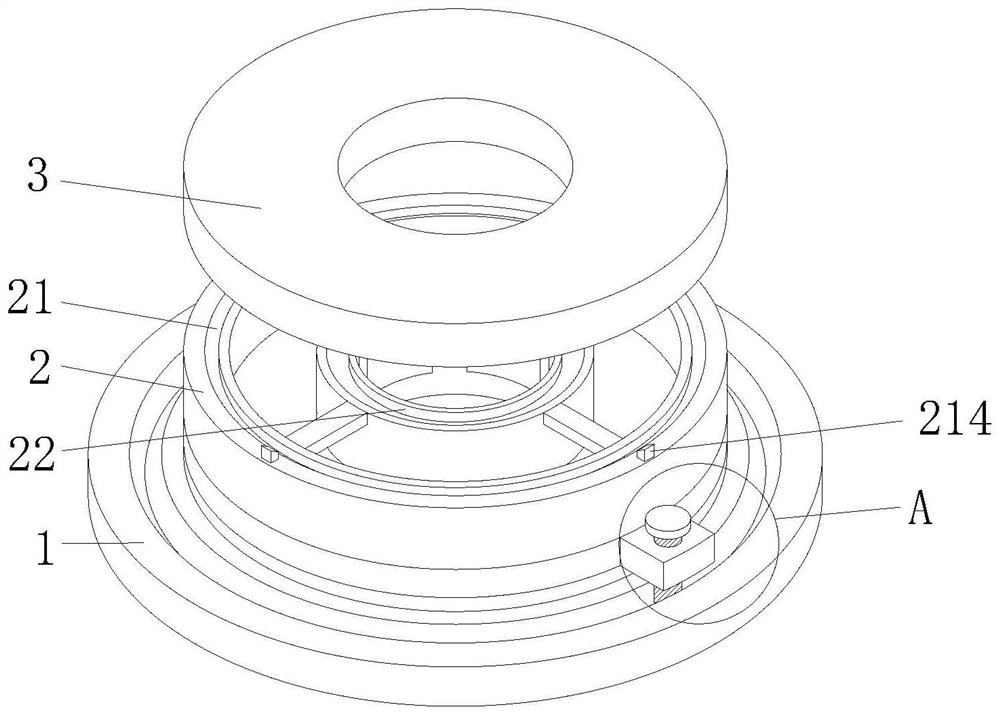

[0034] Example 1: See Figure 1-4 , a special positioning plate for lead-type electronic component anti-sticker, including a mounting chassis 1, the upper surface of the mounting chassis 1 is fixedly connected with a fixed plate 2, and the upper surface of the fixed plate 2 is provided with a cover plate that matches the fixed plate 2 3. Both the cover plate 3 and the fixed plate 2 are provided with a positioning hole 4, so electronic components are placed in the positioning hole 4 for positioning.

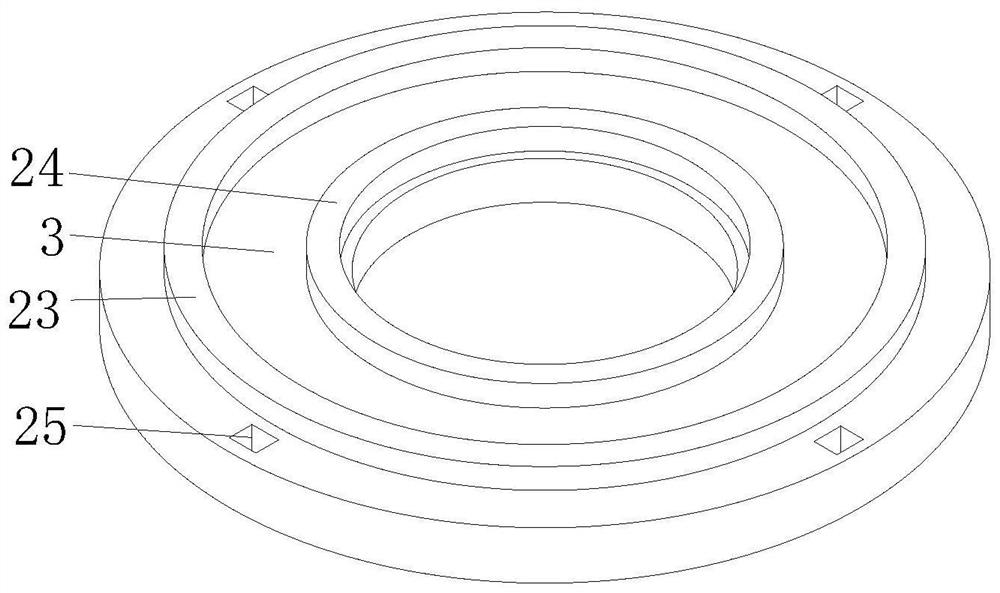

[0035] Further, a first mortise 21 and a second mortise 22 are respectively provided on the upper surface of the fixed plate 2, and at the same time, the lower surface of the cover plate 3 is fixedly connected with the first mortise 21 and the second mortise 22 respectively. The first tenon block 23 and the second tenon block 24, so that the cover plate 3 is installed on the fixed plate 2 through tenon and tenon, in this way the sealing between the cover plate 3 and the fixed plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com