Assembly system and method for packaging web material in a roll

A technology of rolls and components, applied in the directions of sending objects, transportation and packaging, thin material handling, etc., can solve problems such as waste, increase of web materials, and increase of material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

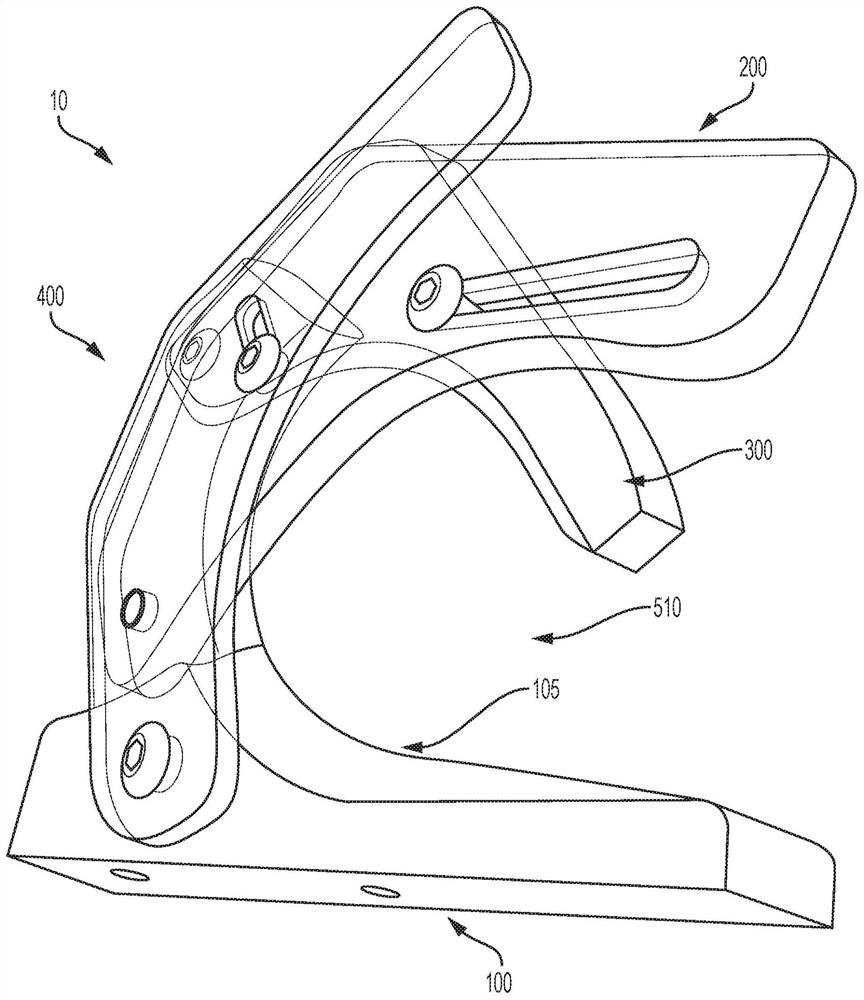

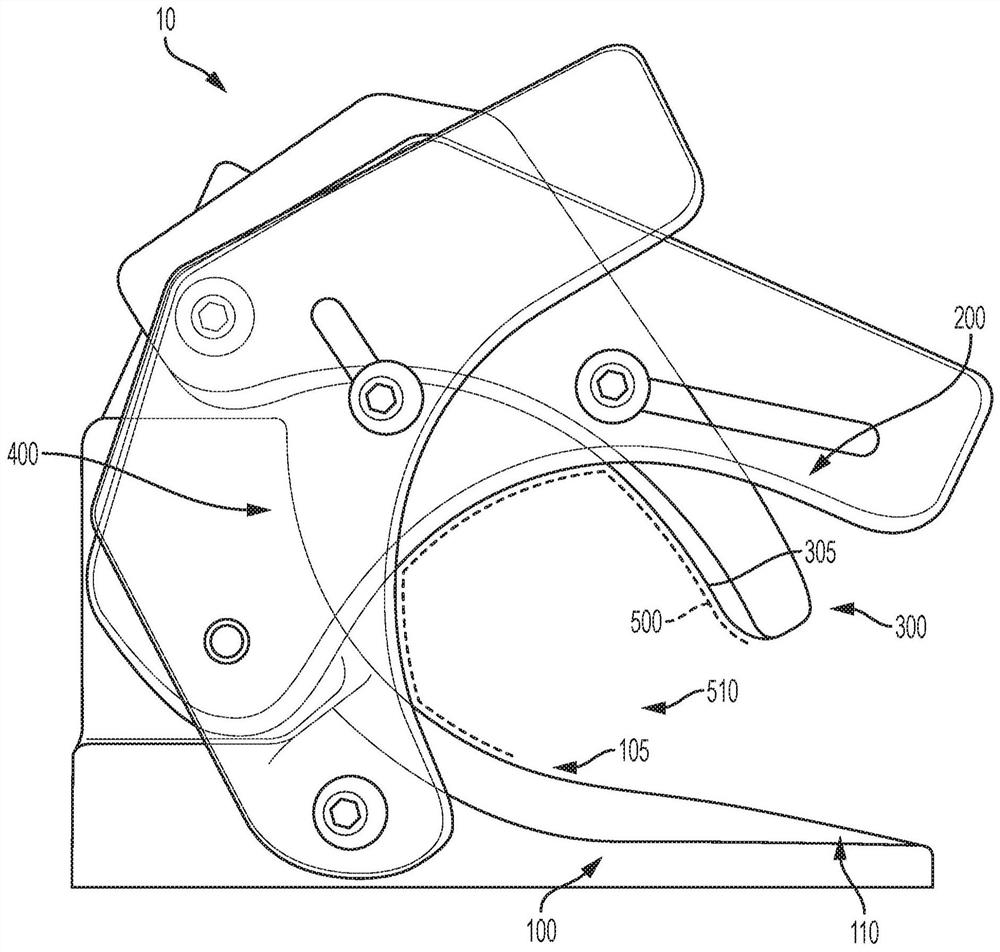

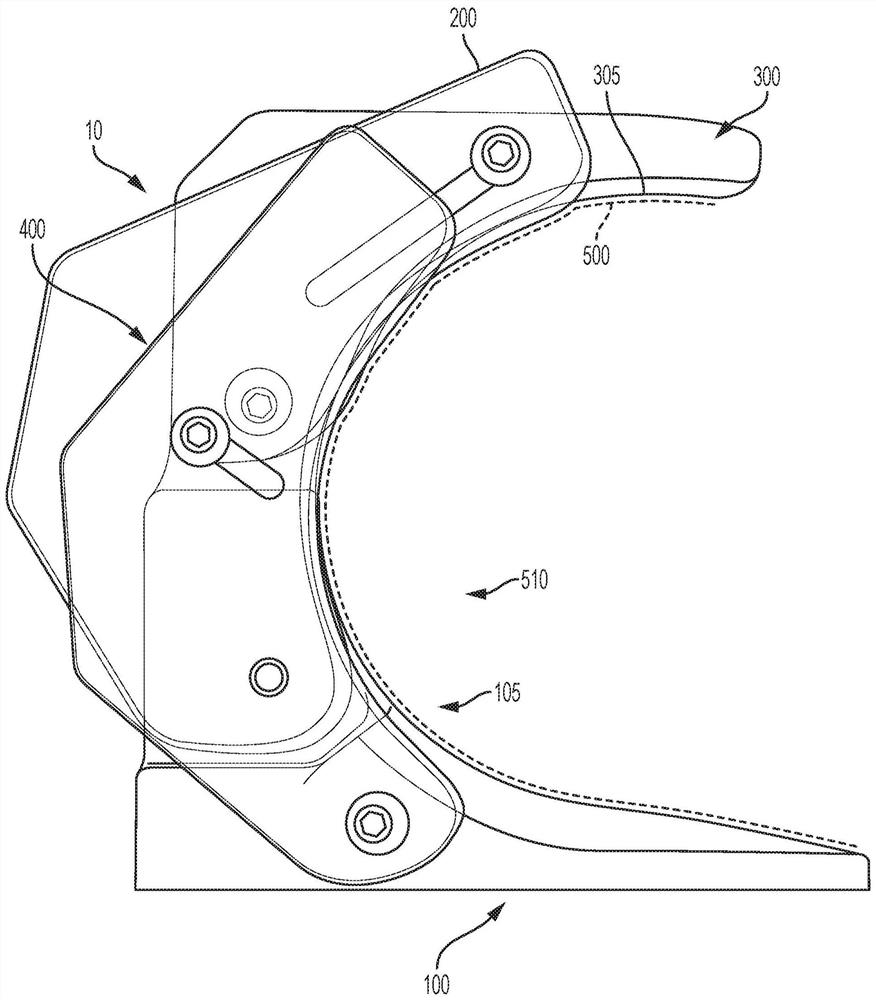

[0034] Reference will now be made in detail to various exemplary embodiments of the disclosed subject matter, which are illustrated in the accompanying drawings. The structure and corresponding method of operation of the disclosed subject matter will be described in conjunction with the detailed description of the roll-up assembly and system.

[0035] The roll-up assemblies, systems, and methods presented herein can be used for packaging, shipping, storage, and commercialization of a wide variety of web materials. The disclosed subject matter is particularly useful for efficiently packaging food storage containers (eg, slider bags) formed from webs into rolls.

[0036] In accordance with the subject matter disclosed herein, a roll-up assembly generally includes a base member having a concavely arcuate feed surface defining an upwardly extending ramp, and a first intermediate member. The first intermediate member is movably coupled to the base member. The roll-up assembly als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com