Filtering device for producing emulsifier by using food protein as raw material

A filter device and protein technology, applied in the direction of filtration separation, fixed filter elements, chemical instruments and methods, etc., can solve the problems of filter hole blockage, inconvenient cleaning, and reduced filtration efficiency, so as to prevent filter holes from being blocked, Improve the filtering effect and increase the flowable area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

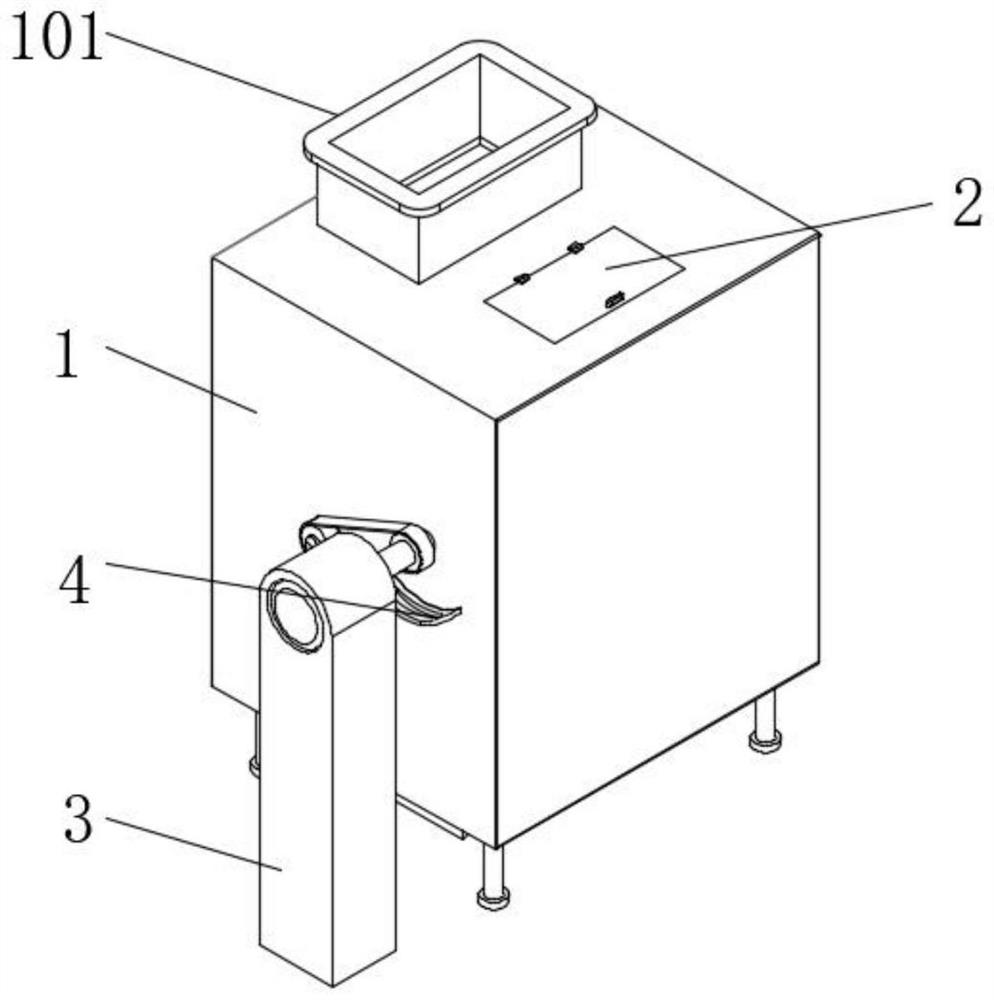

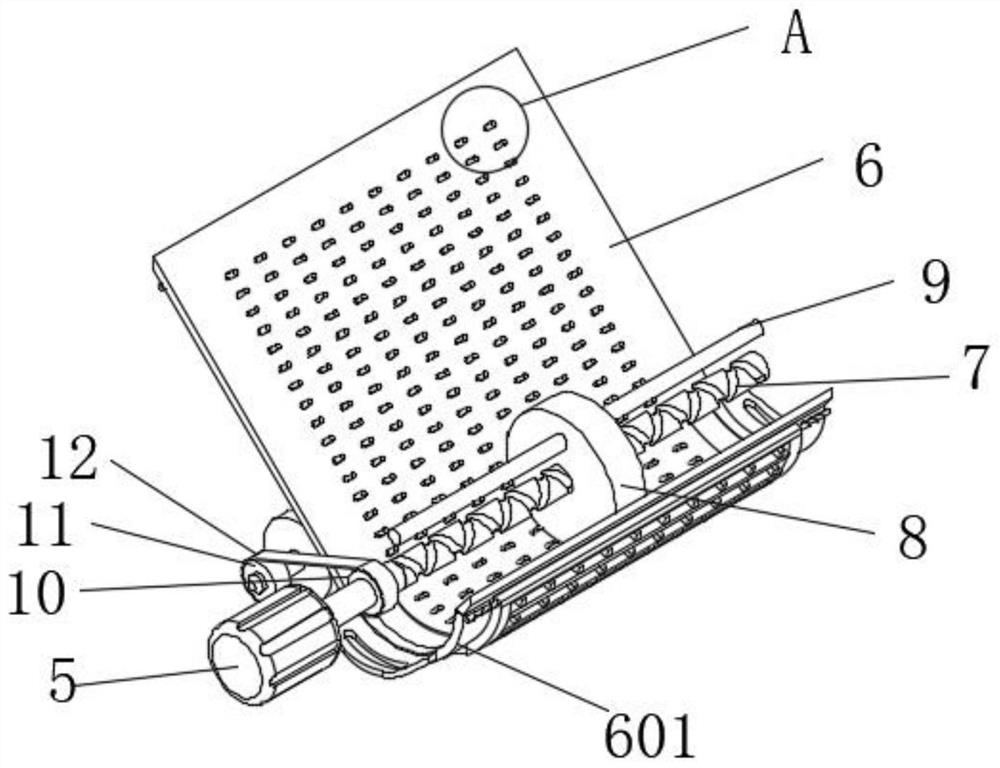

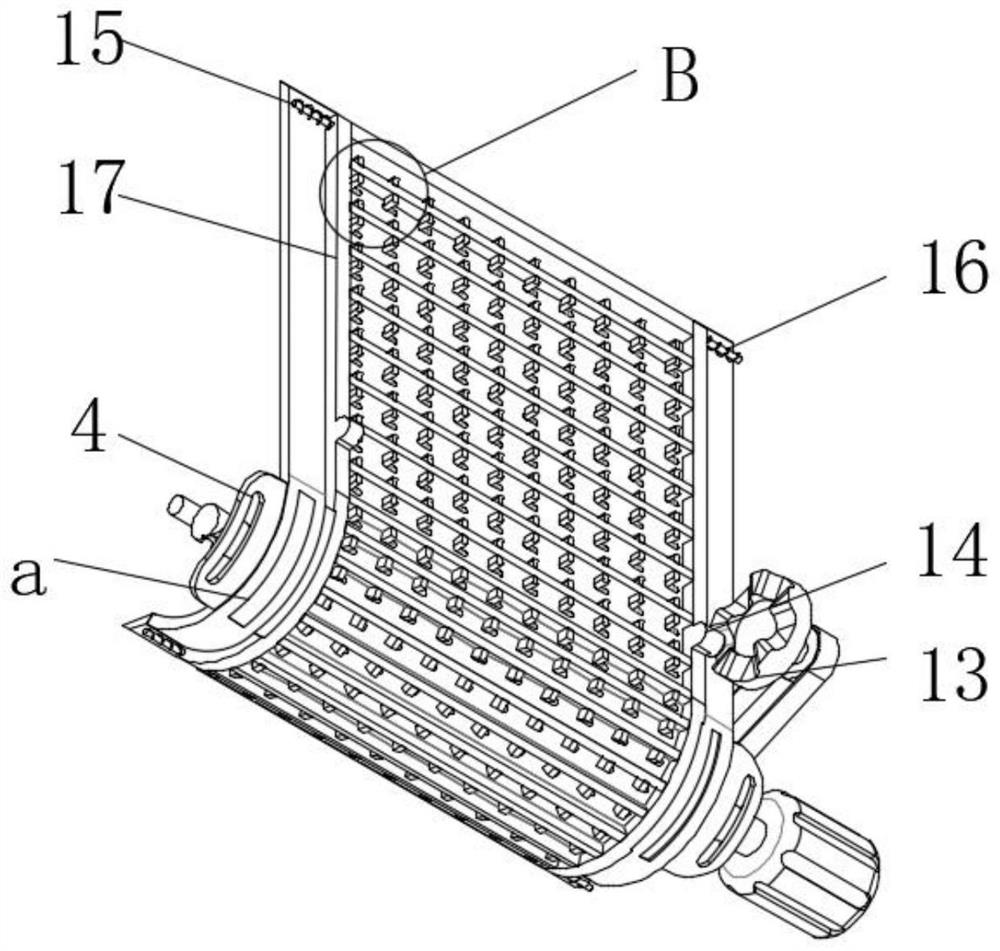

[0036] Refer Figure 1-10 A filter device for producing an emulsifier is produced by a food protein as a raw material, including the box 1 and the filter plate, and the upper surface of the casing 1 is fixedly connected to the feed hopper 101, and the lower surface is fixedly connected with several arrays distribution legs 102, filter plate The filter plate is mounted inside, the filter plate includes a planar filter plate 6 and the curve filter plate 601, the planar filter plate 6 and the surface of the curve filter plate 601 have several filter holes B, filter hole B is a waist hole, a plane filter The plate 6 is tilted in the casing 1, and the emulsifier enters the impact planar filter plate 6 from the feed hopper 101, and the arc surface filter plate 601 is fixed to the lower end of the planar filter plate 6, and the arc surface filter plate 601 is provided with two directions. The screw 7, the bidirectional screw 7 is rotated, and the bidirectional screw 7 is slidably in the t...

Embodiment 2

[0044] like Figure 1-10 As shown in the present embodiment, the present embodiment is substantially the same, preferably, the drive disc 13 is further fixed to the shaft 1302, and the rotating shaft 1302 is rotated and the casing 1 is connected to the casing, and one end is fixedly connected to the driven belt, from the movable tape 11 With the belt 12, the belt 12 is fitted with the active pulley 10, and the active pulley 10 is mounted on the output shaft of the motor 5, the motor 5, the active pulley 10, the driven belt 11 and the belt 12 are located outside the casing 1 An organic base 3 is also provided on the side of the box 1, and the motor 5 is mounted in the base 3.

[0045] In this embodiment, the motor 5 can drive both the bidirectional screw 7 and the shaft 1302 by the pulley transmission, thereby interconnect the motion of the push plate 8 with the movement of the back head 19, so that the two simultaneously, improve the cleaning impurities. efficient.

Embodiment 3

[0047] like Figure 1-10 As shown in the present embodiment, the present embodiment is substantially identical, preferably, the case 1 is provided with a main chamber D and a sub-cavity C located on both sides of the main chamber D, the secondary cavity C is located on the lower side of the slaglet A, the main The cavity D is located directly below the planar filter plate 6 and the arc filter plate 601, and the secondary cavity C communicates with a slag tube 20, the main chamber D communicates with the discharge tube 21, the slag tube 20 and the discharge tube 21 are located in the case 1. bottom.

[0048] In this embodiment, the emulsifier passes through the plane filter 6 and the filter plate 601 into the main chamber D, then directly from the discharge tube 21, the sympathy is passed through the slaglet A into the second cavity C, and then passed The slag tube 20 is discharged.

[0049] It should be noted that the impurities in the flush filter hole need to ensure that the emul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com