Concrete plant spraying and dust falling system

A concrete and factory area technology, applied in the direction of separation method, use of liquid separation agent, separation of dispersed particles, etc., can solve the problems that the spray system cannot spray, etc., and achieve the goal of increasing water pressure, improving spray effect, and good spray effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following is attached Figure 1-5 The application is described in further detail.

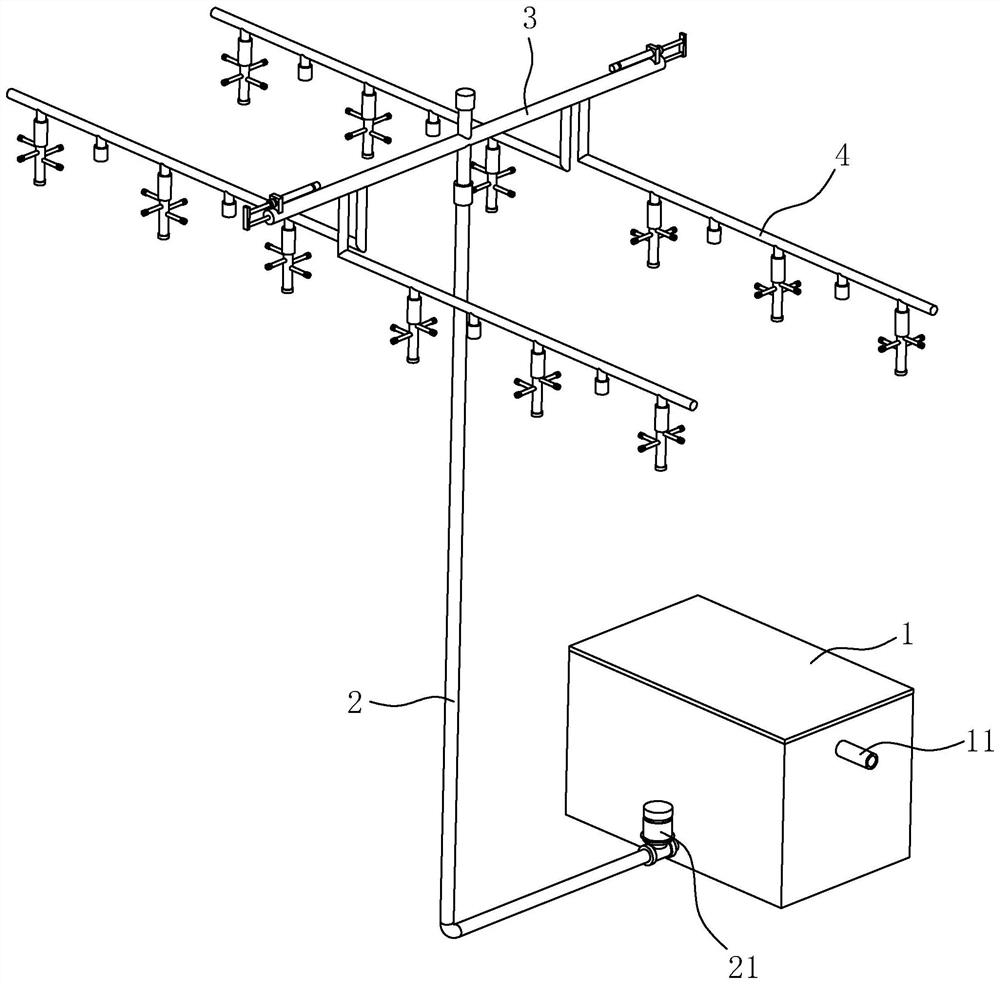

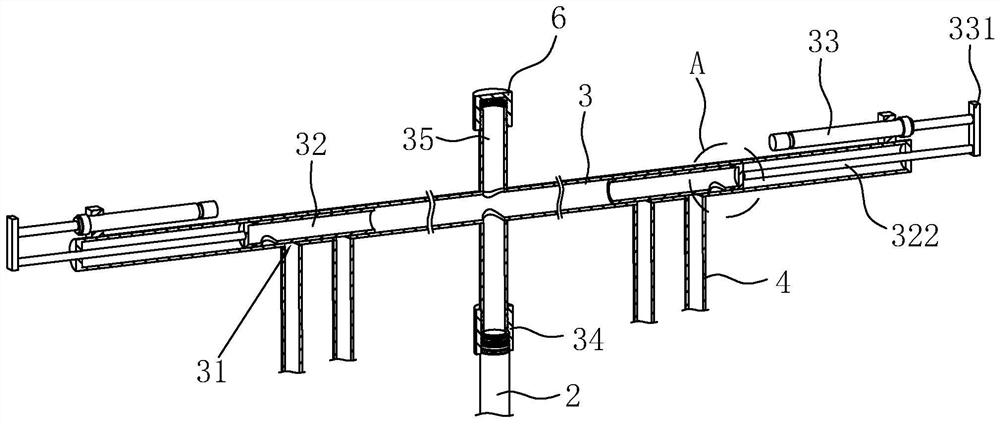

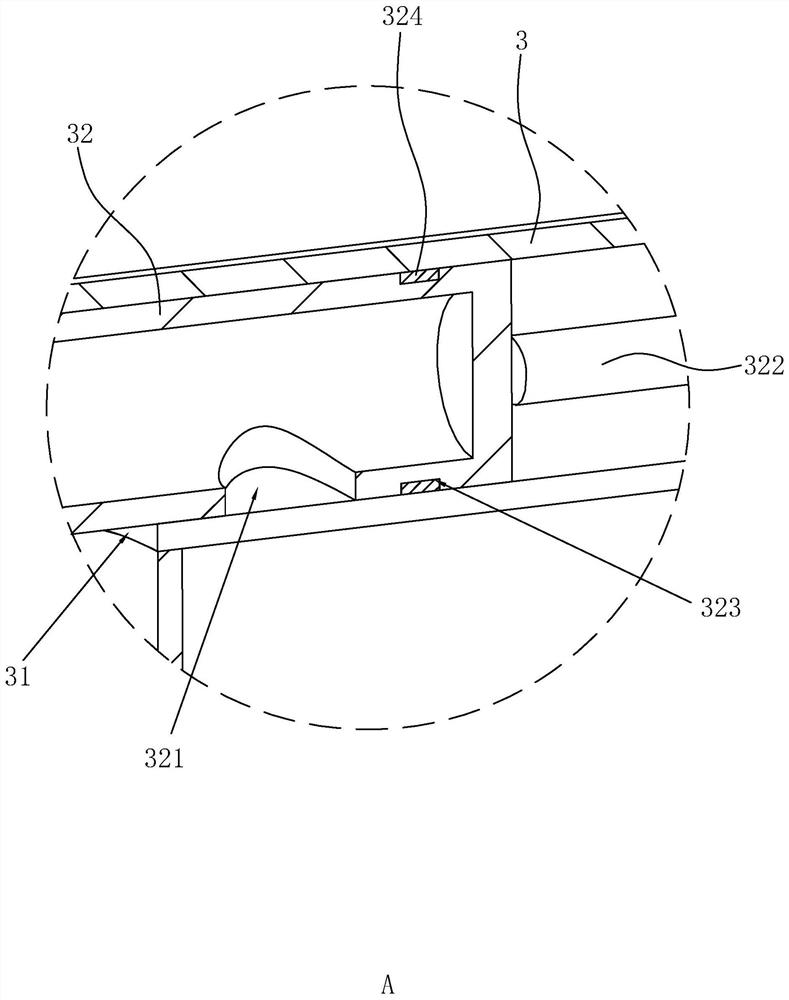

[0038] The embodiment of the present application discloses a sprinkler and dust suppression system in a concrete factory area. refer to figure 1 , a sprinkler and dust reduction system for a concrete factory area, comprising a water tank 1 and a water delivery pipe 2, one end of the water delivery pipe 2 is connected with a water pump 21, the water pump 21 is connected with the water tank 1, and the end of the water delivery pipe 2 far away from the water tank 1 is connected with a water guide pipe 3, The two ends of the water guide pipe 3 are closed, and the side wall of the water guide pipe 3 is connected with a plurality of spray pipes 4. The angle and length of the spray pipe 4 can be adjusted according to the actual working conditions, and are installed in different areas of the factory area; The water tank 1 is connected with a water inlet pipe 11, and the water inlet pipe 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com