Construction waste transportation system attached to building body

A construction waste and transportation system technology, applied to buildings, building components, building structures, etc., can solve the difficulty in ensuring the efficiency and quality of building waste cleaning methods, construction waste cleaning and recycling cannot form a complete system, construction waste cleaning Low efficiency and other problems, to achieve the effect of reducing pollution cleaning costs, improving the quality of green construction, and reducing accidents caused by high-altitude parabolic injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

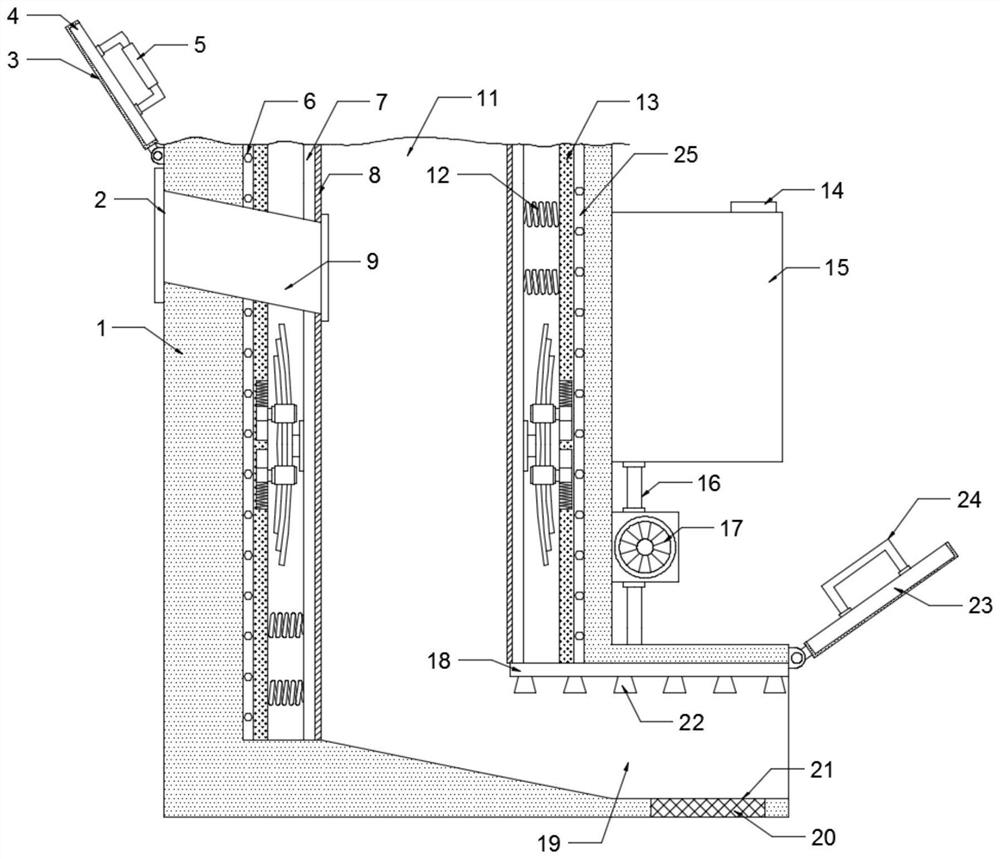

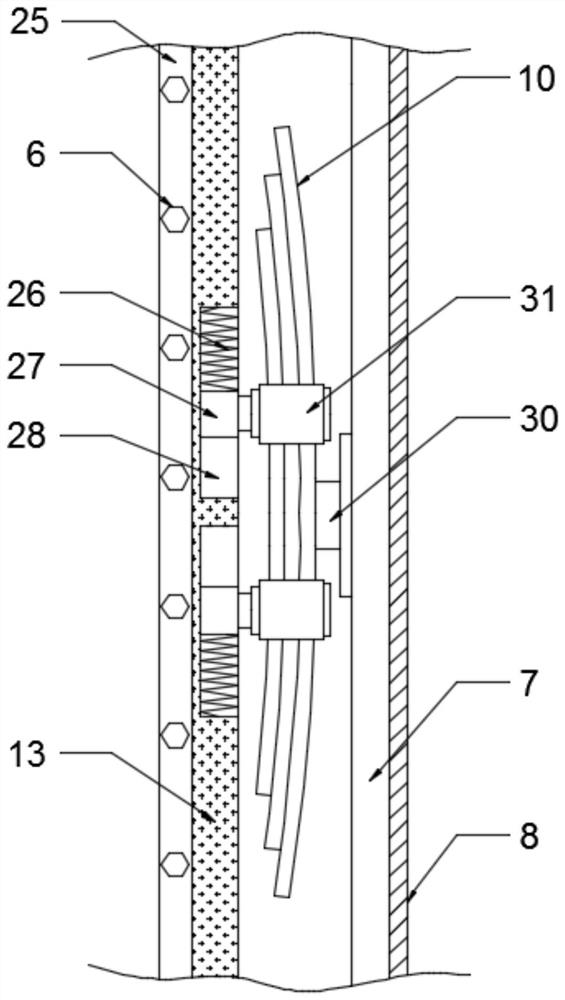

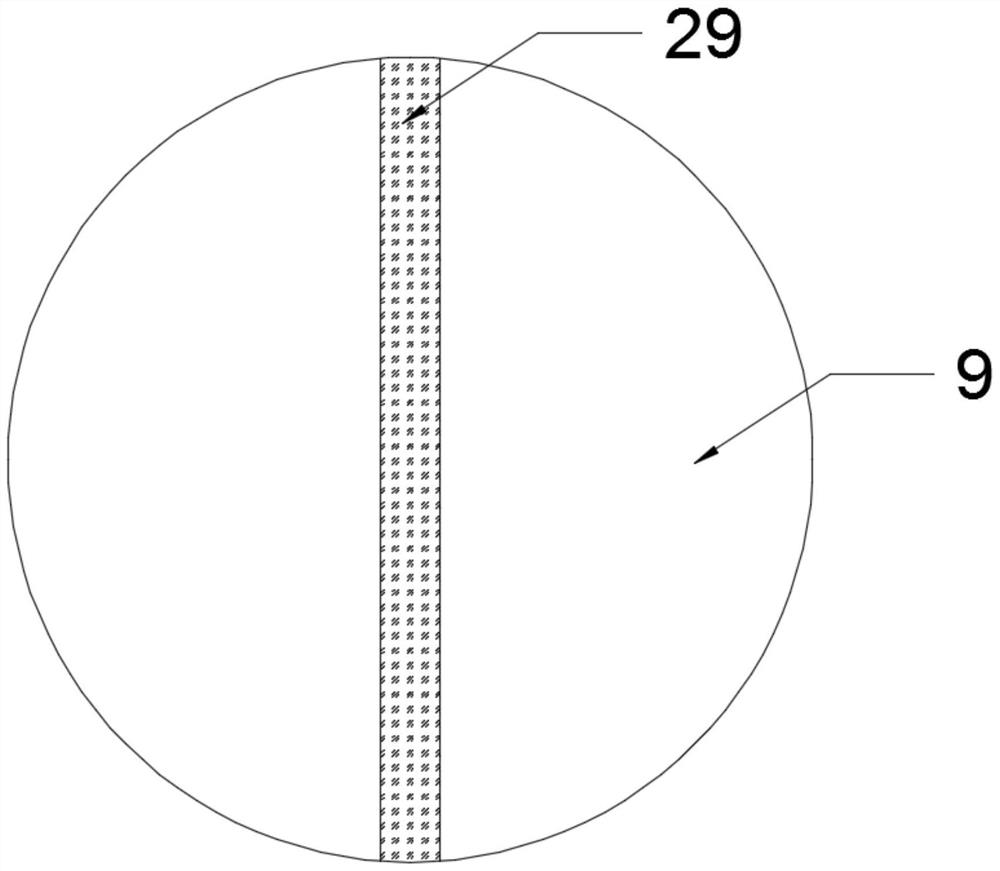

[0023] see Figure 1-3 , a construction waste transportation system attached to a building, comprising a building wall 1 and a waste channel 11, a plurality of feed ports 2 are arranged between the waste channel 11 and the building wall 1, and a plurality of feed ports 2 are arranged above the feed port 2 A sealing baffle 4, the sealing baffle 4 is rotatably connected with the building wall 1, the sealing baffle 4 controls the opening and closing of the feed port 2, the feed port 2 is connected to the feed channel 9, and the feed port 2 is connected to the feed channel 9. One end of feed channel 9 away from feed port 2 is connected with feed channel 9, and sealing plate 13 is fixedly installed on both sides of described garbage channel 11, and described sealing plate 13 can be connected with building wall body 1 by angle steel-25 and fastening bolt 6. Disassemble the fixed connection, in order to protect the garbage channel 11 and prevent the garbage from colliding with the si...

Embodiment 2

[0030] see figure 1 , on the basis of Example 1, in order to reduce the dust around the slag outlet 19 and avoid floating in the air to damage human health, a water tank 15 is arranged on the side wall of the building wall 1, and a water injection port 14 is arranged above the water tank 15. A water pump 17 is arranged below the water tank 15, and the water pump 17 is connected to the water tank 15 through a first water pipe 15. Two second water pipes 18 are arranged above the slag outlet 19, and the second water pipe 18 is connected to the first water pipe 15 above. connected, the lower surface of the second water pipe 18 is equidistantly provided with a plurality of nozzles 22, and the water pump 17 transports the water in the water tank 15 to the nozzles 22 through the first water pipe 16 and the second water pipe 18, and the nozzle 22 sprays the water In the slag outlet 19, dust reduction of rubbish is realized.

[0031] Further, in order to discharge the water in the sla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com