Treatment method for improving biodegradability of refractory organic wastewater

A technology of organic wastewater and treatment methods, which is applied in water/sewage treatment, water treatment parameter control, chemical instruments and methods, etc., and can solve the problems of large equipment investment and high transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~16

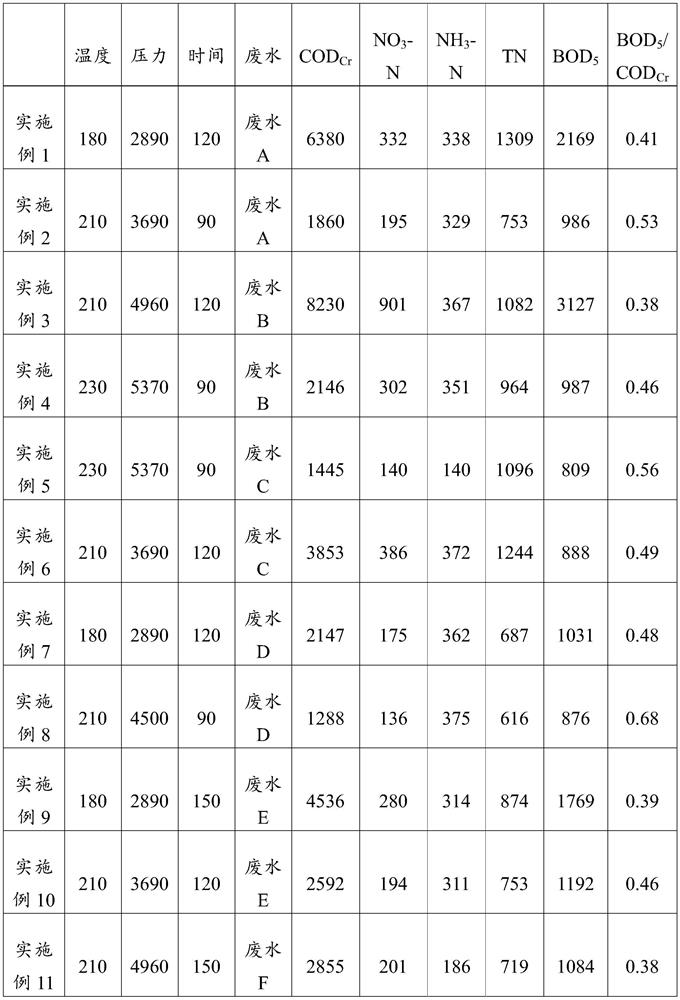

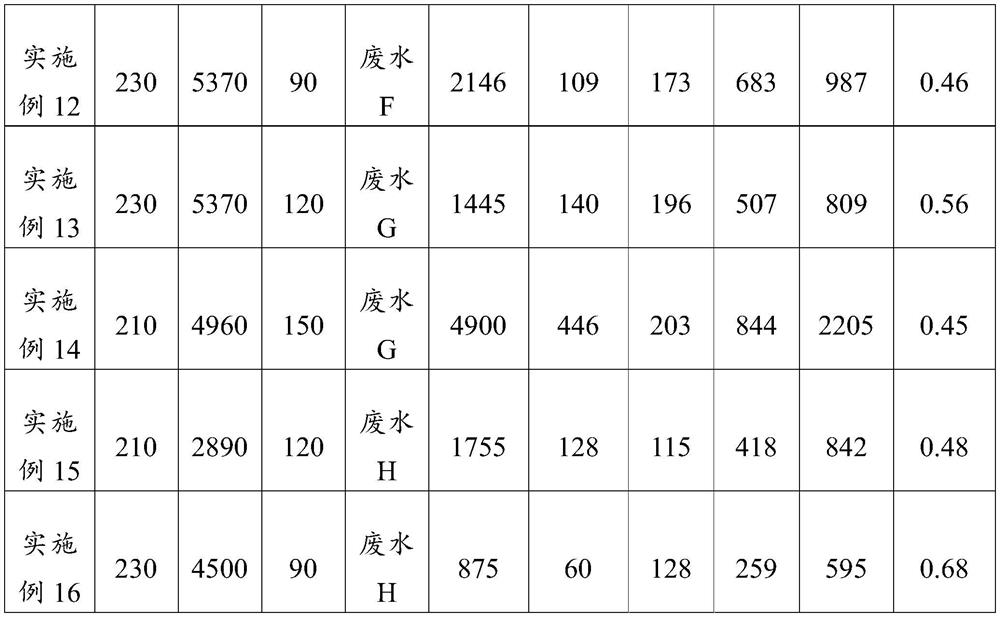

[0034] The reaction parameters of the treatment methods for improving the biodegradability of refractory organic wastewater described in Examples 1 to 16 are shown in Table 2, where the unit of temperature is °C, the unit of pressure is kPa, and the unit of time is min.

[0035] The treatment methods for improving the biodegradability of refractory organic wastewater described in Examples 1 to 16 are as follows: placing the organic wastewater in a reactor, adding an oxidant, and reacting at a certain temperature and pressure to obtain the treated wastewater. Organic waste water.

[0036] The NO of the treated organic wastewater described in Examples 1 to 16 was tested respectively 3 -N, COD Cr , NH 3 -N, TN, BOD 5 , BOD 5 / COD Cr , where NO 3 -N, COD Cr , NH 3 -N, TN, BOD 5 The unit is mg / L, and the results are shown in Table 2.

[0037] Table 2

[0038]

[0039]

[0040]

[0041] It can be seen from Table 1 and Table 2 that the COD degradation efficiency in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com