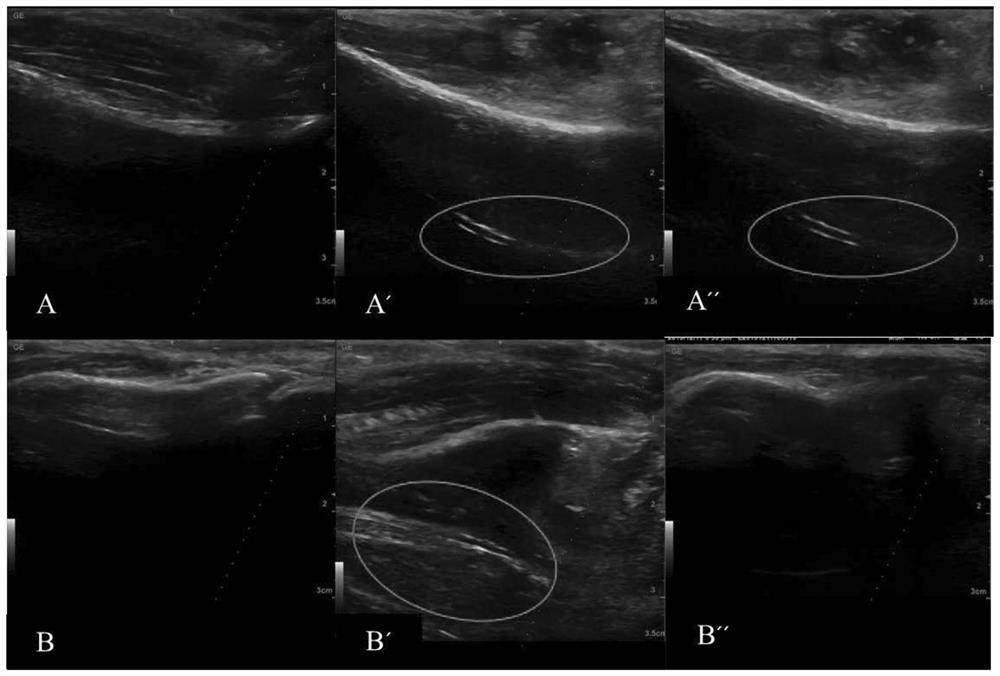

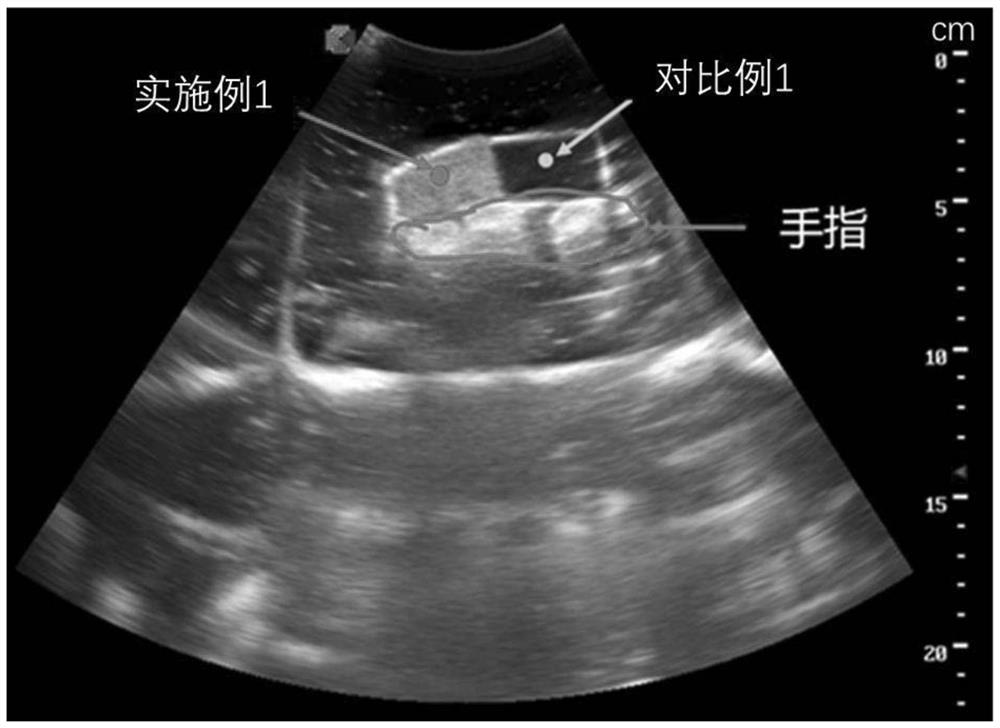

Self-healing ultrasonic phantom material as well as preparation method and application thereof

A self-healing, ultrasonic technology, applied in the field of ultrasonic imaging materials and medical materials, can solve the problems of not providing good self-healing performance, affecting performance, and unsatisfactory long-term stability of materials, achieving excellent ultrasonic imaging performance, low cost, Realize the effect of large-scale production application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

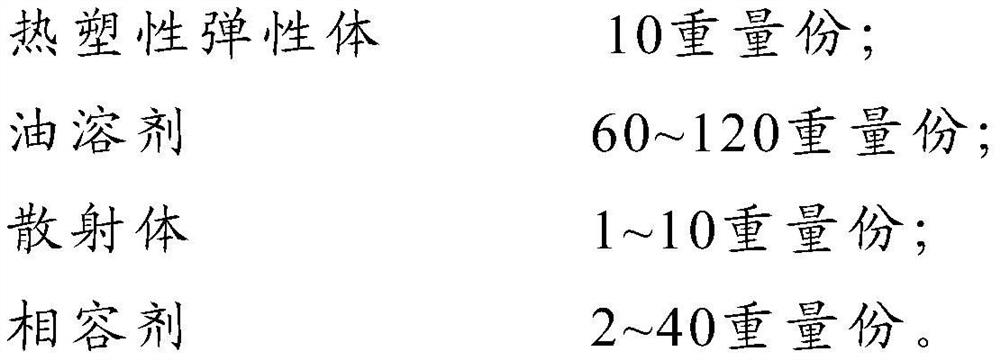

[0084] The present invention also provides a preparation method for the above-mentioned self-healing ultrasonic phantom material, including:

[0085] Heating to dissolve the thermoplastic elastomer, oil solvent, scatterer and compatibilizer into a uniform solution, degassing and cooling.

[0086] Further, the method also includes the following sub-steps:

[0087] Step 1', oil solvent, scatterer and compatibilizer are heated and stirred until becoming a homogeneous solution;

[0088] Step 2', add the thermoplastic elastomer, heat and stir until it becomes a homogeneous solution.

[0089] The oil solvent, the scatterer and the compatibilizer are premixed with heating and stirring to form a homogeneous solution system, so that the scatterer and the compatibilizer can be more uniformly dispersed in the thermoplastic elastomer gel. If the thermoplastic elastomer, oil solvent, scatterer and compatibilizer are added at one time, the viscosity of the reaction system will be high, an...

Embodiment 1

[0120] Get mineral oil 360g, hydroxyethyl cellulose 6g, ethyl cellulose 10g, diethylene glycol ether 38g, propylene glycol butyl ether 18g. Mix the above-mentioned raw materials and place them in a three-necked flask, raise the temperature to 170°C, heat and stir for 5 hours until it becomes a uniform solution; then add 40 g of pre-dried SEBS to the system, heat and stir for 2.5 hours until it becomes a uniform solution, pour the solution into Put it in the mold, and heat it in a high-temperature oven at 170°C for 35 minutes to remove air bubbles, cool to room temperature, and demould to obtain the tissue-mimicking ultrasonic phantom material.

[0121] Wherein, the tissue-imitating ultrasonic phantom material obtained is a gel block with uniform shape, light yellow translucence, and no air bubbles.

Embodiment 2

[0123] Take 60 g of mineral oil, 0.5 g of hydroxyethyl cellulose, 1 g of ethyl cellulose, 3 g of diethylene glycol ethyl ether, and 2 g of propylene glycol butyl ether. Mix the above raw materials and place them in a three-necked flask, raise the temperature to 160°C, heat and stir for 4 hours until it becomes a uniform solution; then add 10 g of pre-dried SEBS to the system, heat and stir for 2 hours to obtain a uniform solution, and pour the solution into the mold , and heated in a high-temperature oven at 160°C for 10 minutes to remove air bubbles, cooled to room temperature, and demolded to obtain tissue-mimicking ultrasonic phantom materials.

[0124] Wherein, the tissue-imitating ultrasonic phantom material obtained is a gel block with uniform shape, light yellow translucence, and no air bubbles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com