Semi-circular pipe jacking machine and construction method

A construction method and pipe jacking machine technology, applied in earthwork drilling, mining equipment, tunnels, etc., can solve the problems of high economic cost and low section utilization rate, and achieve good economic performance, high section utilization rate, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

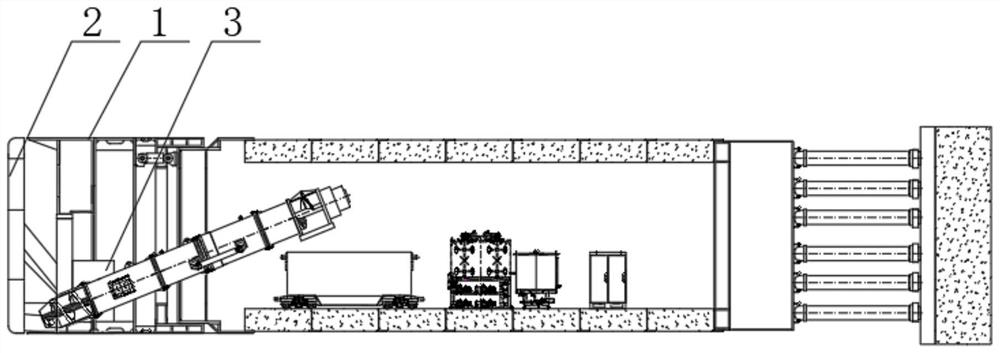

[0038] Such as Figure 1-Figure 7 As shown, the semi-dome tube machine of the present embodiment includes a shield body 1, a swinging cutterhead 2 is installed at the forward end of the shield body 1, and a cutterhead driving device 3 is arranged in the shield body 1, and the cutterhead driving device 3 drives the swinging cutterhead 2 ,

[0039] Cutterhead driving device 3 comprises driving machine, the rocking bar group that links to each other with the output shaft of driving machine,

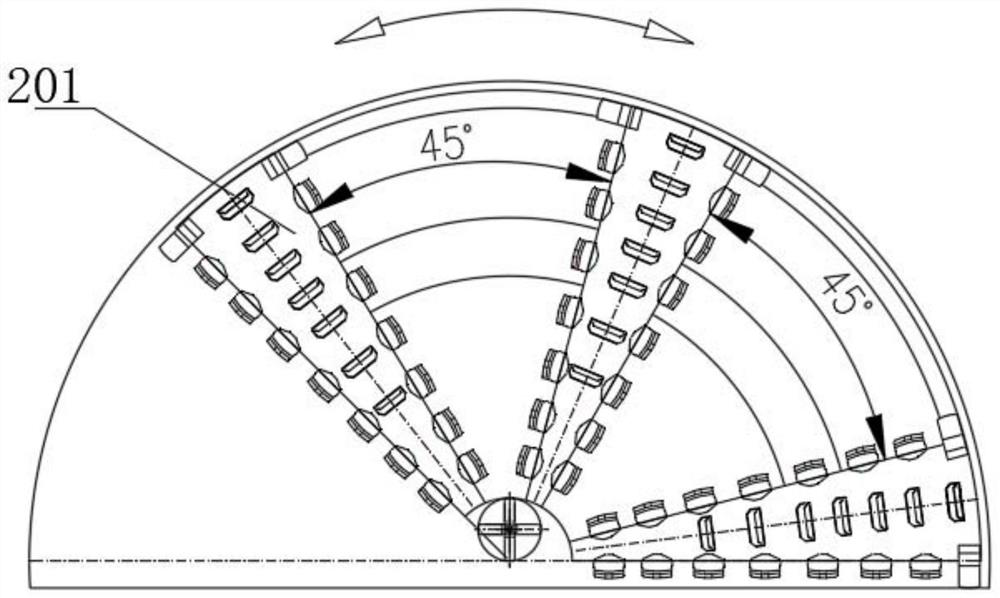

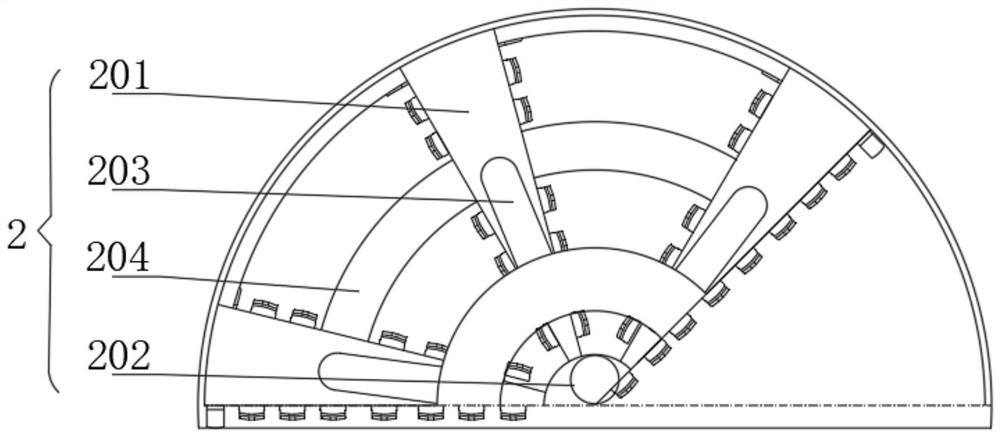

[0040] The oscillating cutter head 2 includes a plurality of cutter head main beams 201 in an annular array, on which there are linear array tools; the end of the cutter head main beam 201 pointing to the center of the oscillating cutter head 2 is connected with a central flange 202, and the central flange 202 is connected to The rocking bar group of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com