Beam-type pumping unit auxiliary brake device with buffering function for oil field

A technology for auxiliary brakes and pumping units, applied in mechanical equipment, drum brakes, brake actuators, etc., can solve problems such as easy slippage and accidental occurrence without protection measures, unable to guarantee automatic locking, etc., to achieve a good lock. Dead function, smooth braking, reducing the effect of dangerous situations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

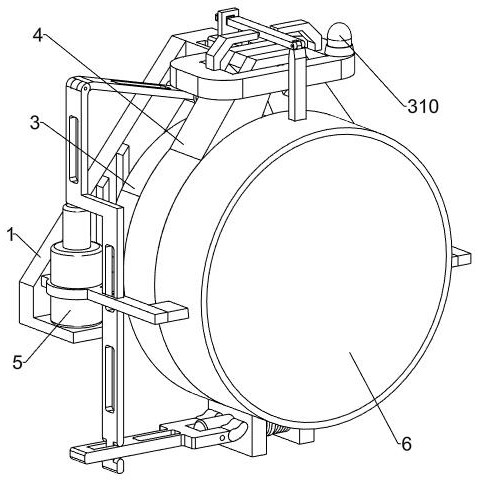

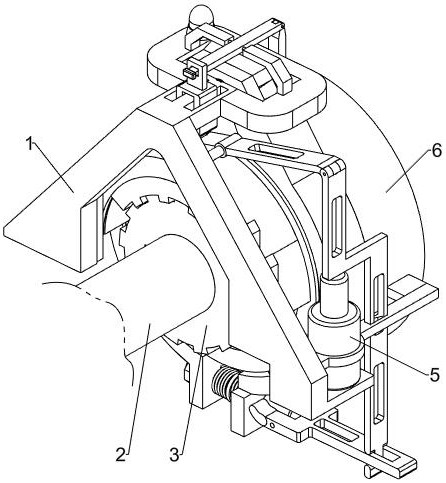

[0029] An auxiliary brake device for a beam pumping unit with a buffer function in an oil field, such as figure 1 and figure 2 As shown, it includes a mounting frame 1, a brake shaft 2, an auxiliary braking device 3, a braking device 4 and a power assembly 5. The mounting frame 1 is fixedly connected to the beam pumping unit, and the braking shaft 2 is the reducer of the beam pumping unit. One output shaft end of the brake shaft 2, the front part of the brake shaft 2 is designed in a stepped shape, and the stepped part of the brake shaft 2 is designed with threads. 3 and braking device 4 are respectively connected with the brake shaft 2 through keys, the braking device 4 is used to brake the pumping unit, and the auxiliary braking device 3 is used to cooperate with the braking of the pumping unit and the locking of the device after braking. The power assembly 5 is fixedly connected to the installation frame 1, and the power assembly 5 is respectively slidably connected with ...

Embodiment 2

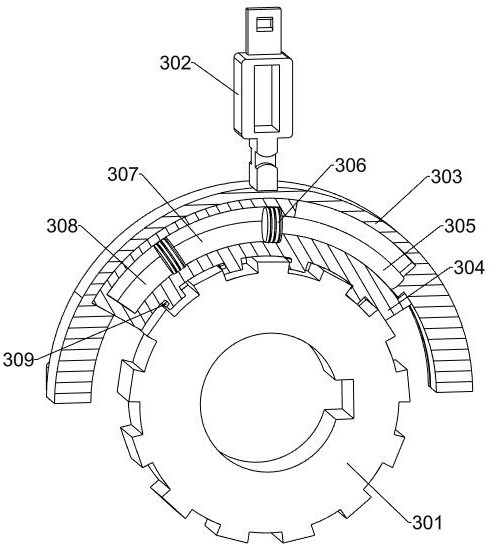

[0042] On the basis of Example 1, such as Figure 9 and Figure 10 As shown, an emergency braking device 6 is also included. The emergency braking device 6 is arranged on the front side of the brake shaft 2. The emergency braking device 6 is arranged on the mounting frame 1. The emergency braking device 6 includes a triangular claw ring 601, a second limit block 602, brake block 603, protective frame 604, second spring 605, third limit block 606 and fourth limit block 607, triangular claw ring 601 is slidably arranged on the front end of brake shaft 2, and second limit block 602 is provided with three , the three second limit blocks 602 are connected to the triangular claw ring 601 by bolts to facilitate the disassembly and reset of the emergency braking device 6, and the rear end faces of the three second limit blocks 602 are fixedly connected with brake blocks 603 and the triangular claw ring 601 respectively. The outside of the three claws is trapezoidal design, the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com