Brake beam assembly system

A technology for assembling systems and braking beams, which can be used in injection devices and other directions to solve problems such as hidden safety hazards, high labor intensity, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above -mentioned purposes, characteristics, and advantages of the present invention more obvious, the following combines the specific implementation methods of the present invention in detail. In the description below, many specific details are explained to fully understand the invention. However, the present invention can be implemented in many other ways that are different from this description. Technical personnel in the art can make similar improvements without violation of the connotation of the invention. Therefore, the invention is not limited by the specific embodiments below.

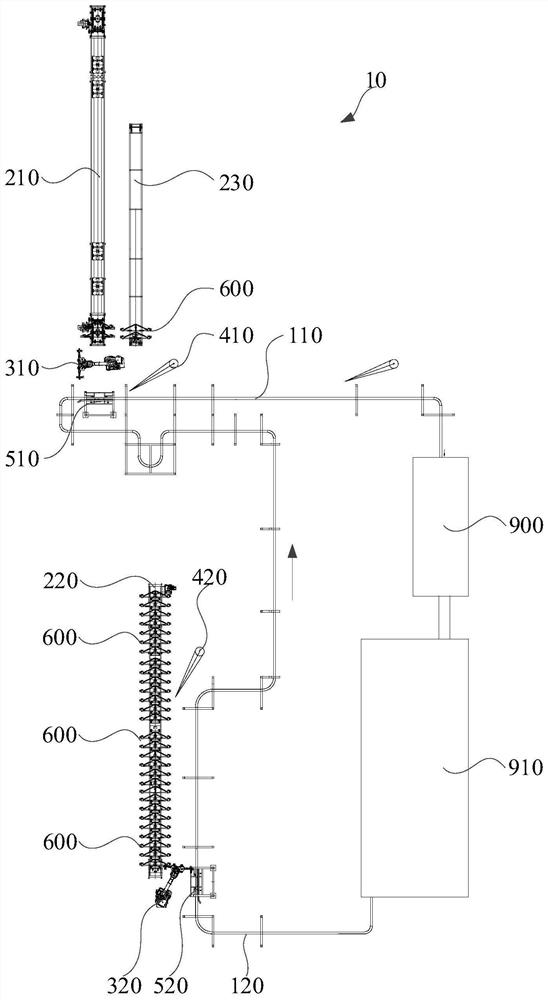

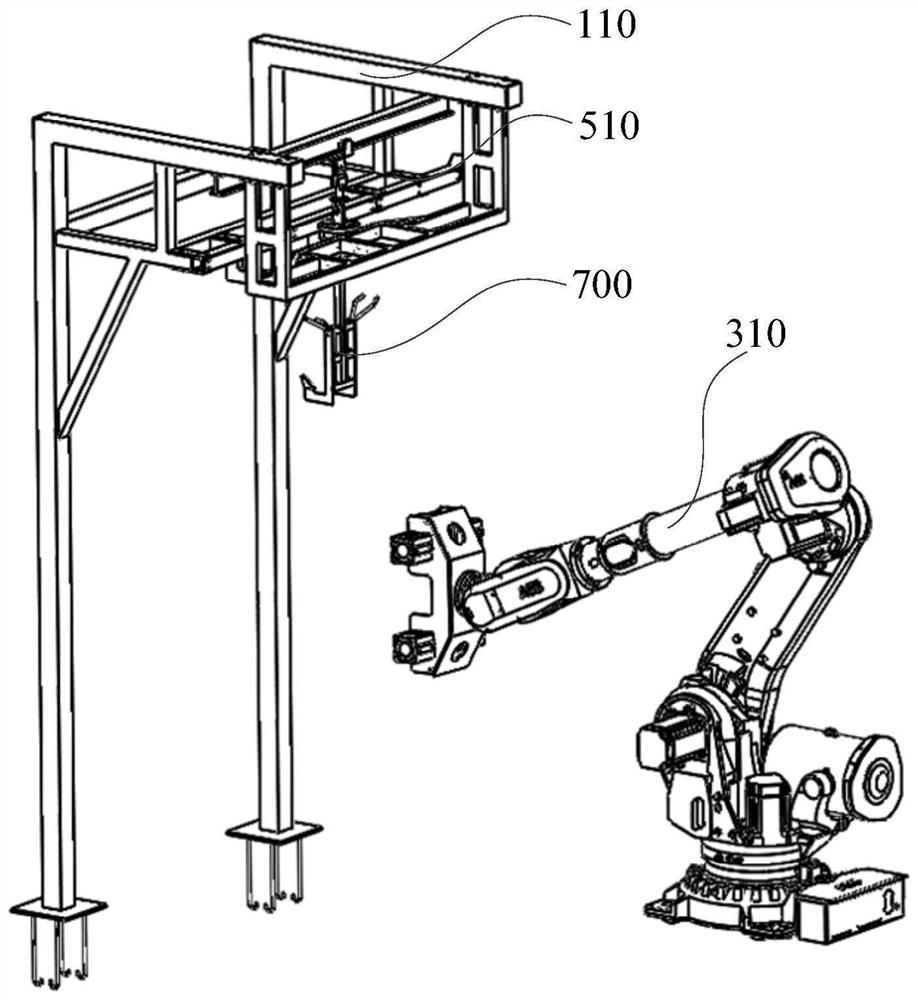

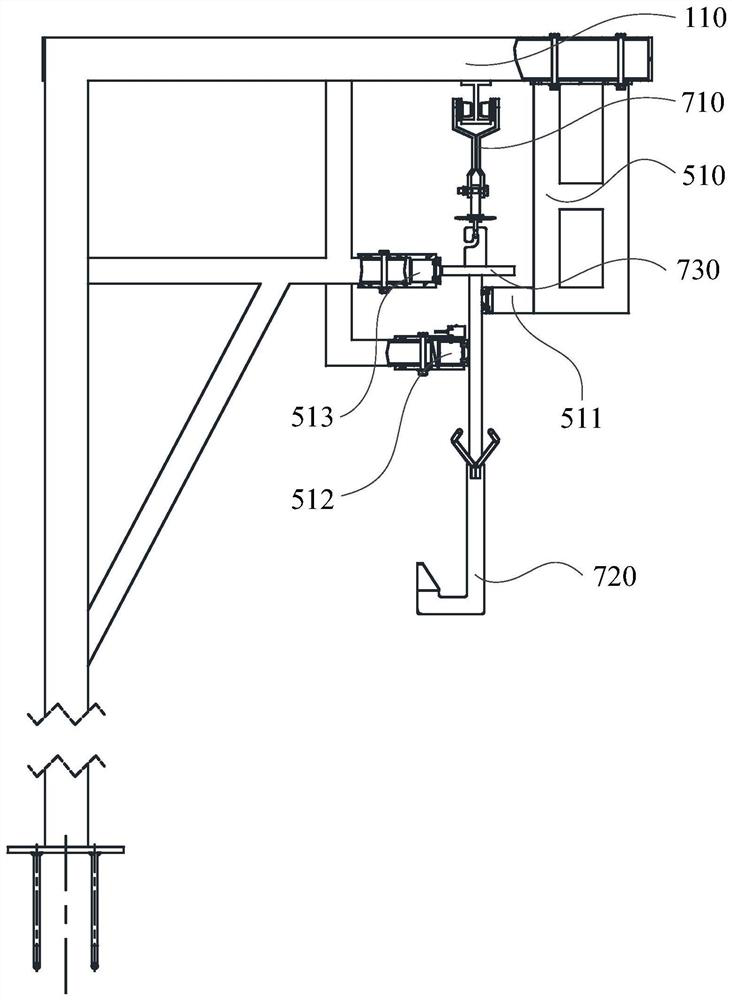

[0028] Reference figure 1 As well as figure 2 and Figure 4In the case of an example, the brake beam assembly system 10, including the first track 110, the hook , 700, the maintenance assembly line 210, and the first mechanical arm 310, which is used to connect to the lacquer workshop 900; 700 includes mobile parts 710 and hook 720. The mobile parts 710 can be moved on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com