Automatic feeding equipment for laser cutting of sheet metal parts

A technology of laser cutting and automatic feeding, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problem of not being able to adjust the position of the suction cup flexibly, and achieve the effect of flexible adjustment of the position of the suction cup and easy gathering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

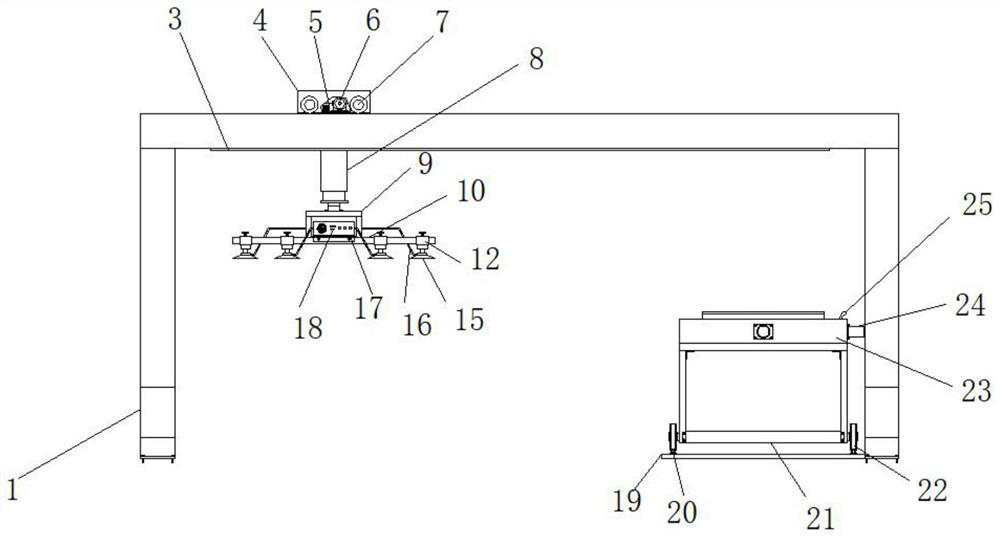

[0027] Example 1: See Figure 1-6 , an automatic feeding equipment for laser cutting of sheet metal parts, comprising a gantry 1, a housing 4 is arranged above the gantry 1, a first hydraulic cylinder 8 is fixedly connected to the bottom of the housing 4, and the first hydraulic cylinder 8 The bottom end is fixedly connected with a fixed frame 9, and the front and rear ends of the fixed frame 9 are welded horizontally with a horizontal frame 10 respectively. There is a bottom plate 19, a frame 21 is arranged on the top of the bottom plate 19, and the top of the frame 21 is fixedly connected with a cover 23; The wheel groove 2, the rear end of the inner bottom of the housing 4 is equipped with a gear box 5, the bottom of the inner housing 4 is fixedly connected with a servo motor 6, the two sides of the front and rear ends of the housing 4 are respectively movably connected with rollers 7, and the top of the bottom plate 19 Slide rails 20 are installed on both sides of the fra...

Embodiment 2

[0031] Embodiment 2: a vacuum pump 18 is installed on the top of the mounting plate 17, and a trachea 16 is arranged between one side of the suction cup 15 and one side of the vacuum pump 18, so that the vacuum pump 18 can vacuum the air in the suction cup 15;

[0032] Specifically, such as figure 1 and Figure 5 As shown, then the first hydraulic cylinder 8 is pushed down, the suction cup 15 is close to the sheet material, the vacuum air pump 18 on the mounting plate 17 is started, and the air in the suction cup 15 is sucked away, and under the action of air pressure, the suction cup 15 will suck up the sheet material , and through the displacement of the upper driving mechanism, the sheet material is transported to the cutting platform, which realizes the function of conveniently sucking up the sheet material for transfer.

Embodiment 3

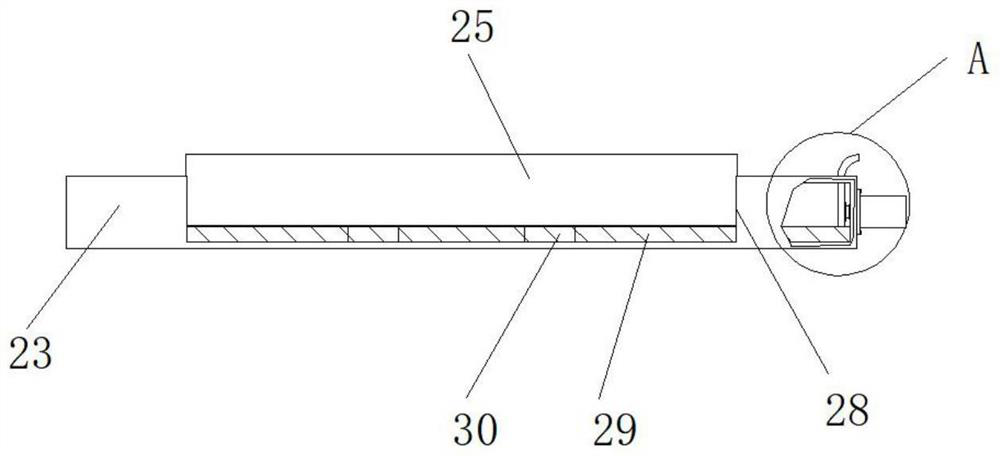

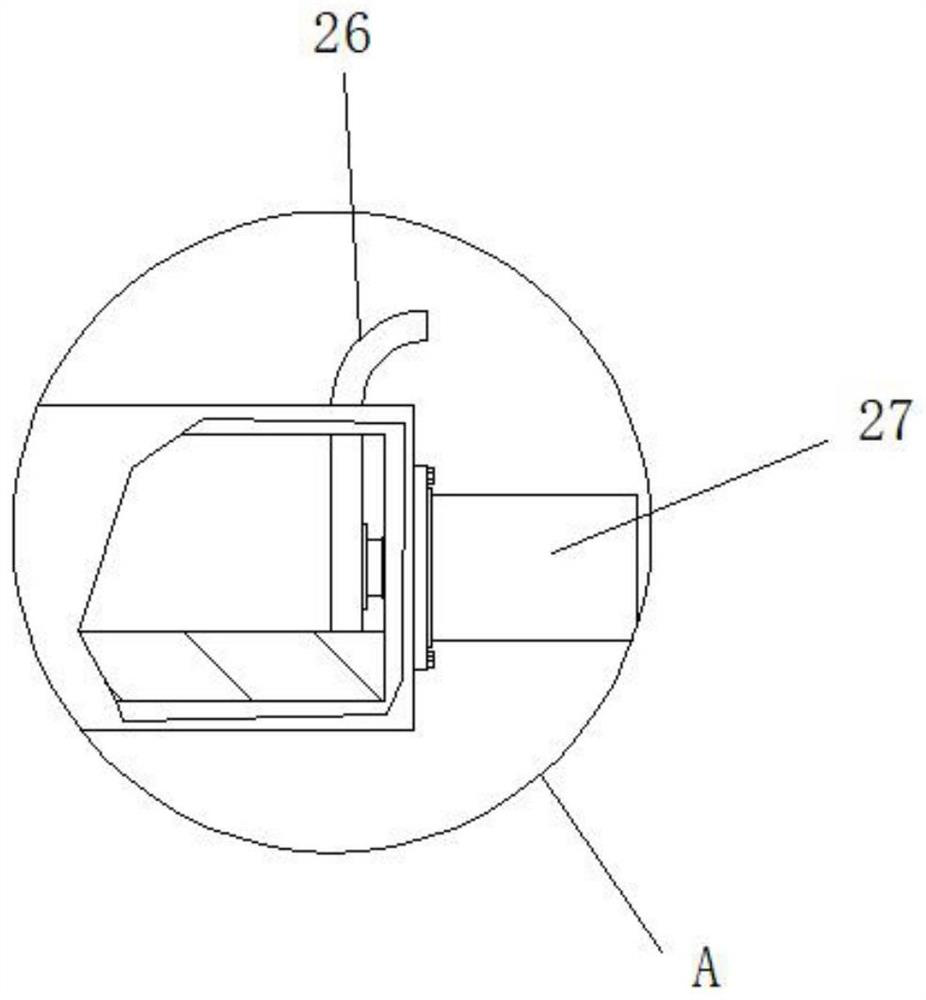

[0033] Embodiment 3: One side inside the casing 23 is provided with a first arcuate pushing plate 25, the front end inside the casing 23 is provided with a second arcuate pushing plate 26, the first arcuate pushing plate 25, the second arcuate pushing plate The top of the board 26 has a certain radian, which is convenient to gather the boards together to prevent overhead;

[0034] Specifically, such as figure 2 and image 3As shown, the forklift forks up the stacked sheets and places them in the casing 23. The radians at the top of the first arcuate push plate 25 and the second arcuate push plate 26 can make the sheets slide down to the bottom of the casing 23 quickly, preventing Occurrence sheet material tilts overhead, causes suction cup 15 to be unable to pick up, has realized the function that prevents sheet material from tilting overhead.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com