Coal sample pneumatic transmission system based on pipeline transfer

A coal sample, pneumatic transmission technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of dirty coal sample bottles, movement restrictions of the transmission frame, easy to block, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

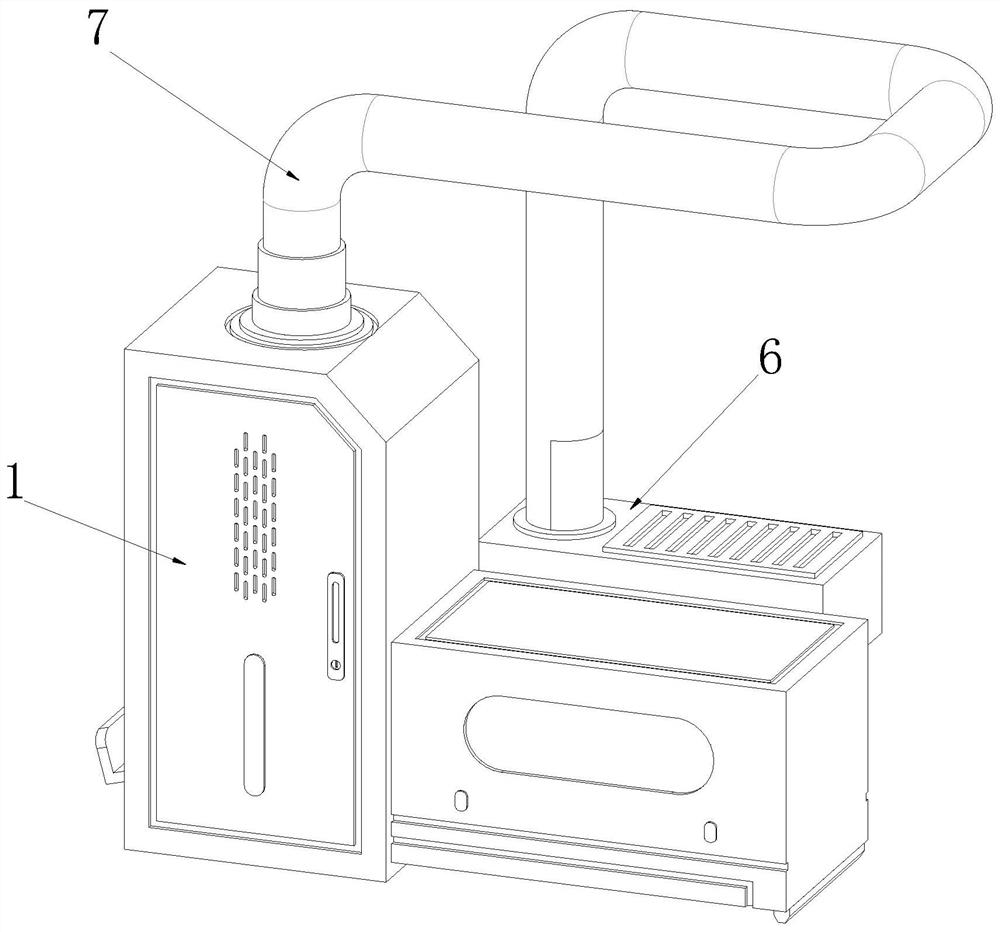

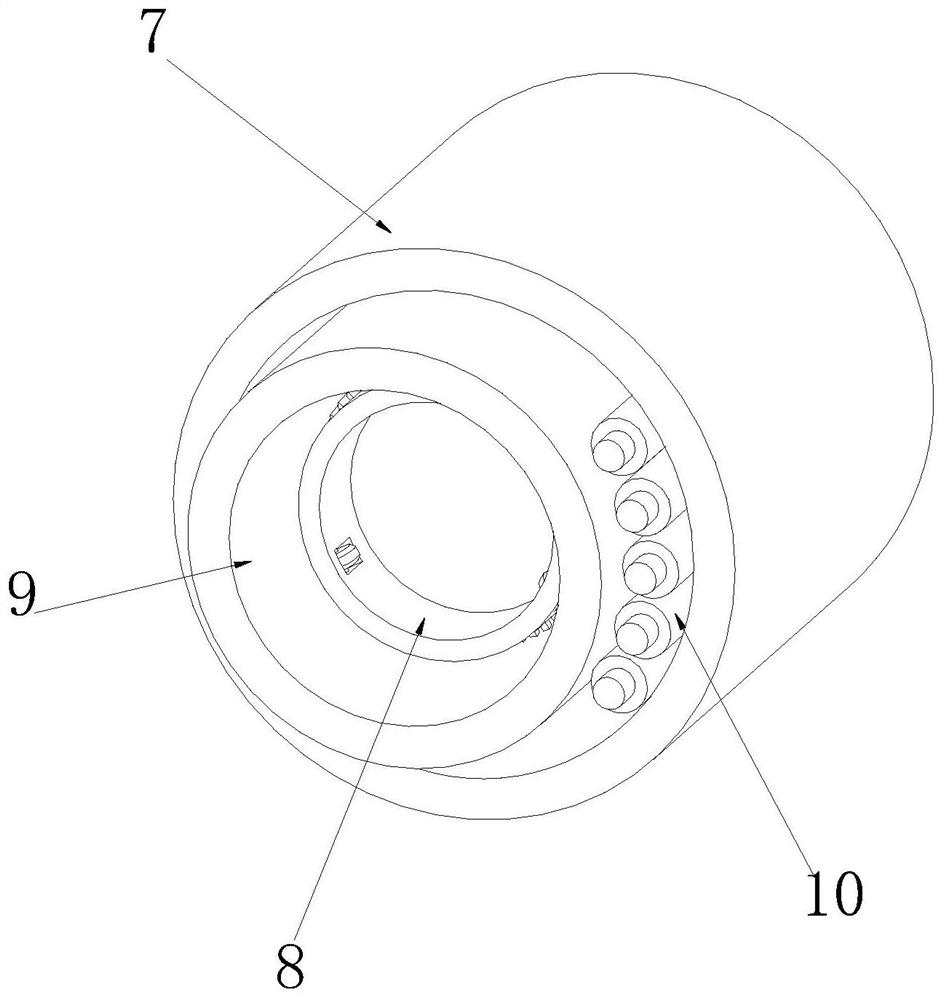

[0040] see Figure 1-5 As shown, the coal sample pneumatic transmission system based on pipeline transfer includes a sample storage workstation 1, a sampling workstation 6, a protective pipeline 7, a transmission frame 8, a transmission pipeline 9 and a communication control cable 10. The upper surface of the sample storage workstation 1 is connected with a The protective pipeline 7, one end of the protective pipeline 7 away from the sample storage workstation 1 is connected with the sampling workstation 6, the inner side wall of the protective pipeline 7 is provided with a transmission pipeline 9, and the inner side wall of the protective pipeline 7 is provided with a communication control cable 10 on the side close to the transmission pipeline 9. The inner wall of the pipeline 9 is provided with a transmission frame 8;

[0041] The power fan connected inside the sample storage station 1 at the position corresponding to the transmission pipe 9 can give the coal sample bottle ...

Embodiment 2

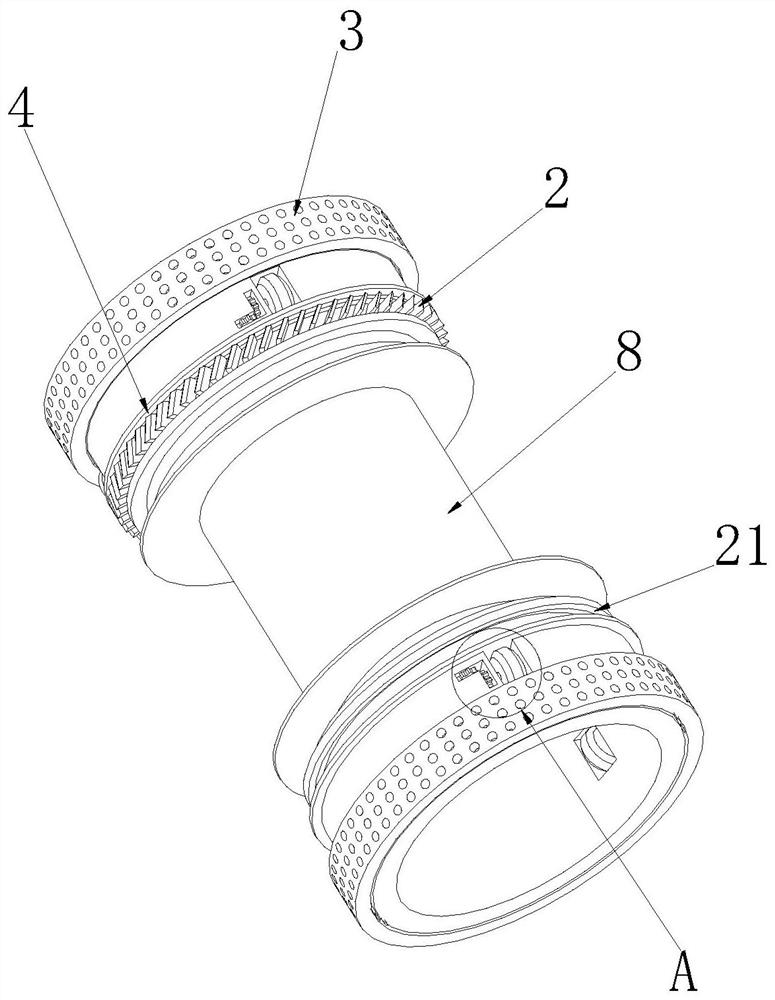

[0046] see Figure 8-9 As shown, the outer side wall of the transmission frame 8 is provided with a miscellaneous conveying mechanism 4 on both sides close to the miscellaneous blade 22, and the miscellaneous conveying mechanism 4 includes a miscellaneous storage box 45. The plate 43, the outer side walls of the second baffle 43 and the first baffle 41 are all in close contact with the inner wall of the transmission pipe 9, so that the first baffle 41, the outer side wall of the transmission frame 8, the second baffle 43 and The four inner walls of the transmission pipe 9 can form a closed annular space, so that the impurities cleaned by the cleaning blade 22 inside the annular space are not easy to spread around, causing the transmission pipe 9, the transmission frame 8 and the coal sample bottle to be dirty. The outer side wall of the plate 43 is provided with a miscellaneous guide hole 44 at the position corresponding to the miscellaneous storage box 45. The side of the out...

Embodiment 3

[0050] see Figure 6-7 As shown, a wiping mechanism 3 is provided on the outer side of the outer side wall of the transmission frame 8. The wiping mechanism 3 includes a second rotating groove 31. The inner side wall of the second rotating groove 31 is slidably connected with a second rotating ring 33. The shape of the second rotating groove 31 is inverted. T-shaped, the shape of the second rotating ring 33 is an I-shaped, and the width of the second rotating ring 33 is larger than the width of the outer opening of the second rotating groove 31, so that the second rotating ring 33 is not easily connected with the second rotating groove 31. In the case of mutual separation, the outer side wall of the second rotating ring 33 is connected with a water-absorbing sponge 32, and the thickness of the water-absorbing sponge 32 is larger than the distance between the transmission frame 8 and the transmission pipe 9, so that the water-absorbing sponge 32 is squeezed inside the transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com