A kind of cualmn shape memory alloy and preparation method thereof

A memory alloy and alloy composition technology, applied in the field of alloy materials and its preparation, can solve the problems of uncontrollable grain orientation, difficult control of single crystal grain orientation, abnormal grain growth, etc., and achieve low cost, easy operation, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

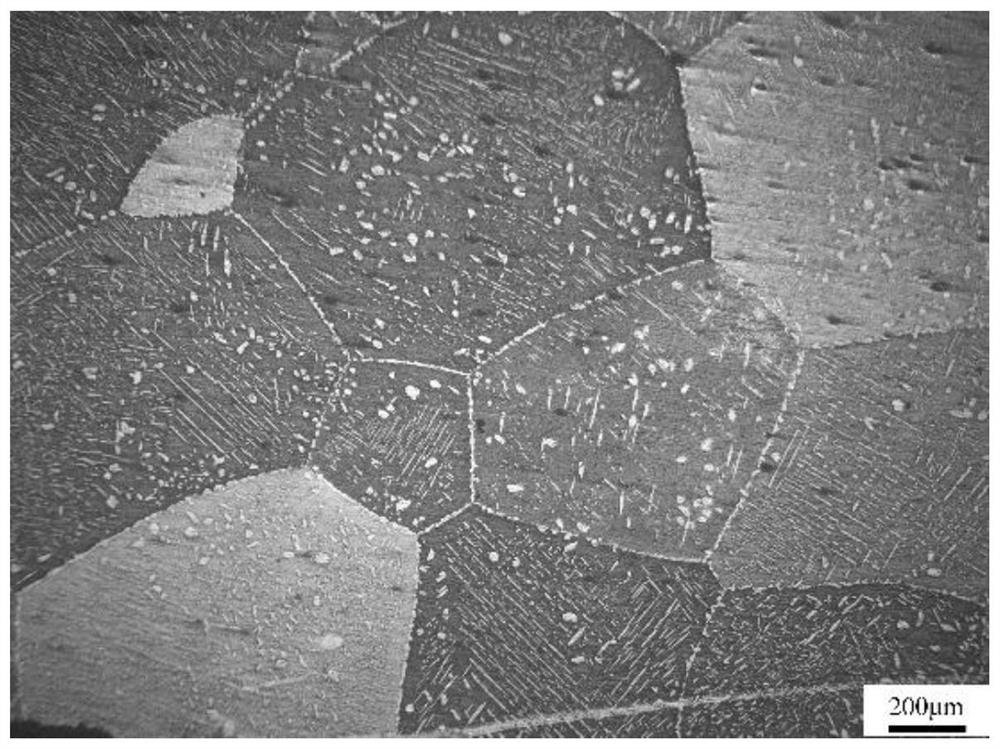

[0035] Select oxygen-free Cu (purity=99.95%), electrolytic Al (purity=99.99%) and electrolytic Mn (purity=99.90%) as raw materials, the alloy composition is 17at.% Al, 10at.% Mn, and the rest are Cu, Put it in a copper crucible of a vacuum induction melting furnace, vacuumize it, and perform arc melting. After repeated melting for 4-5 times, suction casting is performed to obtain a rod-shaped ingot with a diameter of 20 mm.

[0036] Put the ingot into the heat treatment furnace for solution treatment at 800°C for 60min, start hot rolling, press down 2mm for each pass and put it into the heat treatment furnace for 10min after each pass is completed, until the sample thickness is 2mm and stop (reduction rate is 90 %), returned to the furnace for 10 minutes, water quenched, and then cut several standard tensile samples with wire EDM.

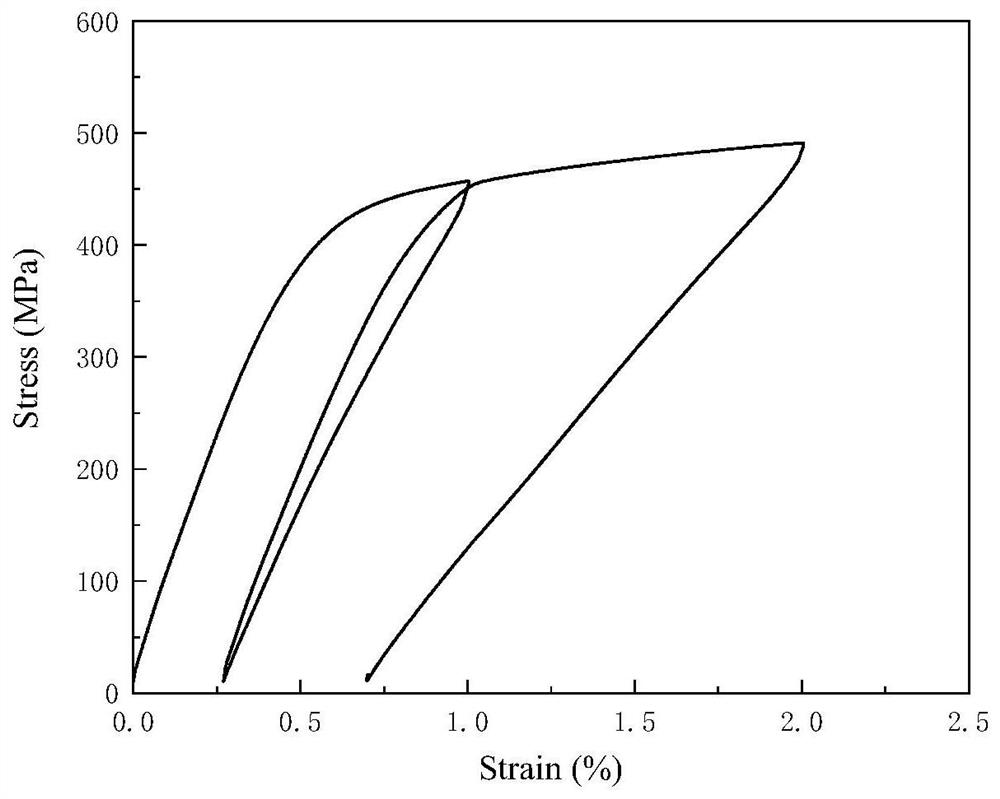

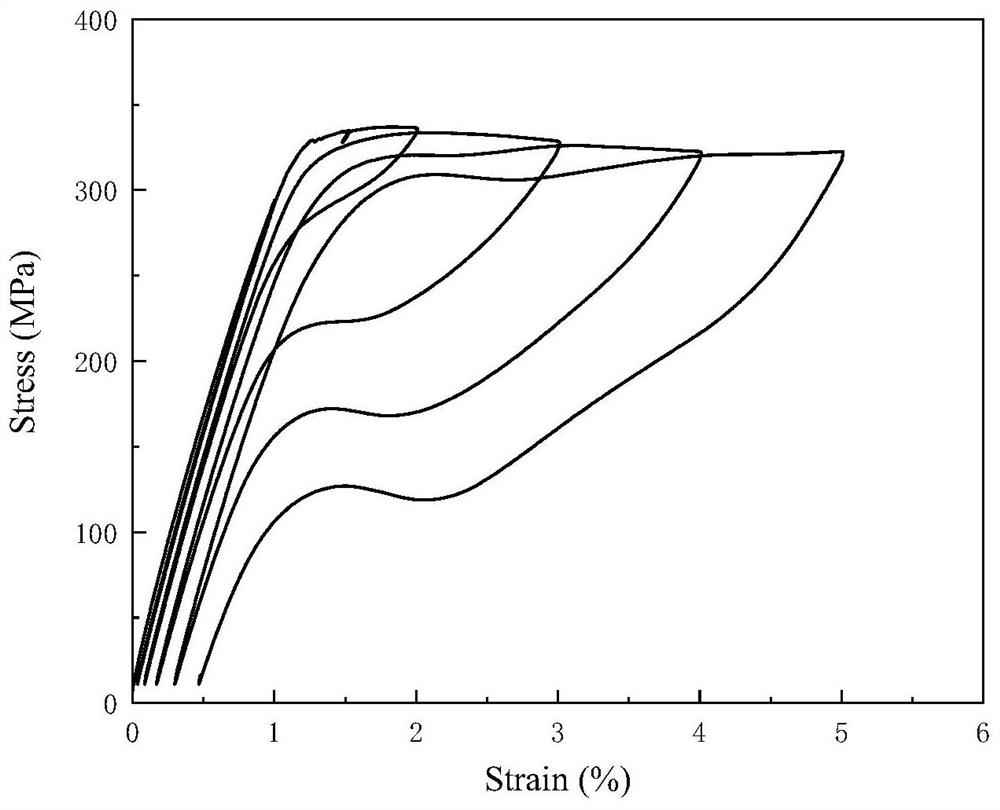

[0037] The sample is cyclically stretched on the stretching machine, and each cycle is loaded with 1% and then unloaded. The cycle stops when the ...

Embodiment 2

[0040] Select oxygen-free Cu (purity=99.95%), electrolytic Al (purity=99.99%) and electrolytic Mn (purity=99.90%) as raw materials, the alloy composition is 17at.% Al, 10at.% Mn, and the rest are Cu, Put it in a copper crucible of a vacuum induction melting furnace, vacuumize it, and perform arc melting. After repeated melting for 4-5 times, suction casting is performed to obtain a rod-shaped ingot with a diameter of 20 mm.

[0041]Put the ingot into the heat treatment furnace for solution treatment at 800°C for 60min, start hot rolling, press down 2mm for each pass and put it into the heat treatment furnace for 10min after each pass is completed, until the sample thickness is 2mm and stop (reduction rate is 90 %), returned to the furnace for 10 minutes, water quenched, and then cut several standard tensile samples with wire EDM.

[0042] The samples were cyclically stretched on a stretching machine, each cycle was loaded with 1% and then unloaded, and the cycle was stopped wh...

Embodiment 3

[0046] Select oxygen-free Cu (purity=99.95%), electrolytic Al (purity=99.99%) and electrolytic Mn (purity=99.90%) as raw materials, the alloy composition is 17at.% Al, 10at.% Mn, and the rest are Cu, Put it in a copper crucible of a vacuum induction melting furnace, vacuumize it, and perform arc melting. After repeated melting for 4-5 times, suction casting is performed to obtain a rod-shaped ingot with a diameter of 20 mm.

[0047] Put the ingot into the heat treatment furnace for solution treatment at 800°C for 60min, start hot rolling, press down 2mm for each pass and put it into the heat treatment furnace for 10min after each pass is completed, until the sample thickness is 2mm and stop (reduction rate is 90 %), returned to the furnace for 10 minutes, water quenched, and then cut several standard tensile samples with wire EDM.

[0048] The sample is cyclically stretched on the stretching machine, and each cycle is loaded with 1% and then unloaded. The cycle stops when the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com