Surgical tool driving system and surgical robot

A surgical tool and drive system technology, which is applied in the field of surgical tool drive system and surgical robot, can solve the problems of complex structure and failure to meet the requirements of drive mode, and achieve the effect of simple principle, high reliability and flexibility, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

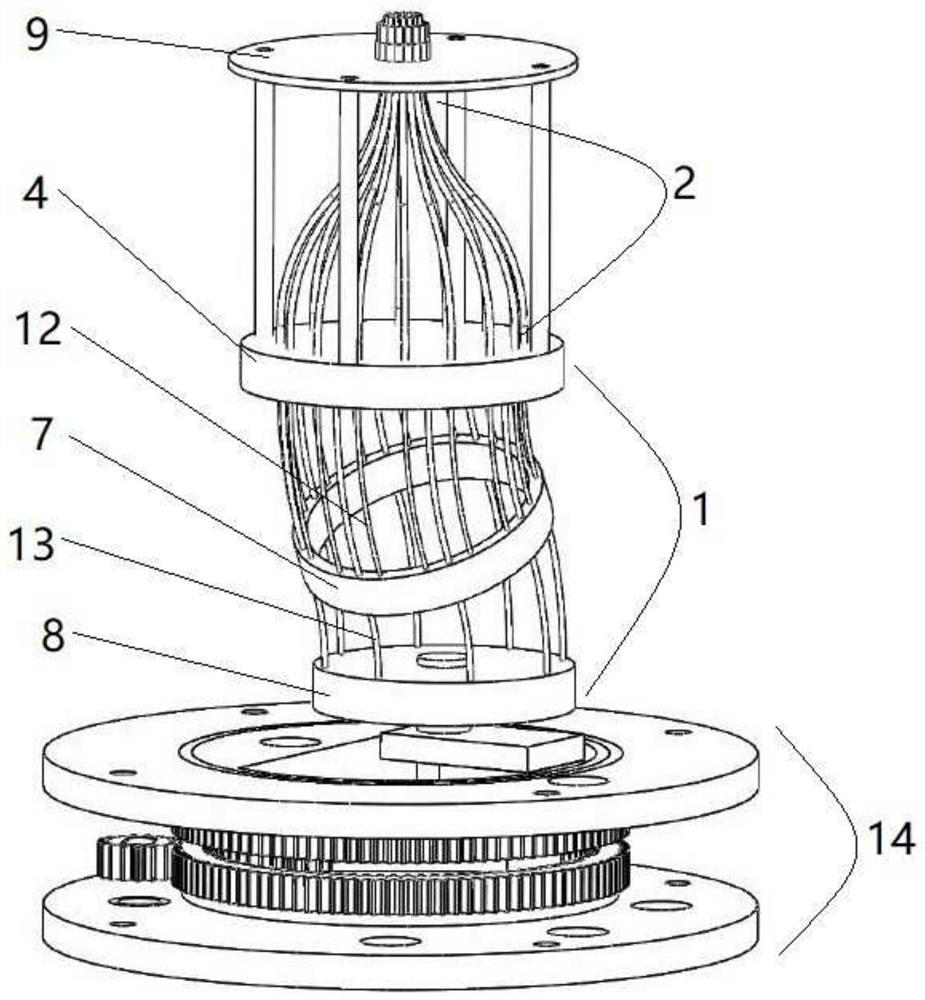

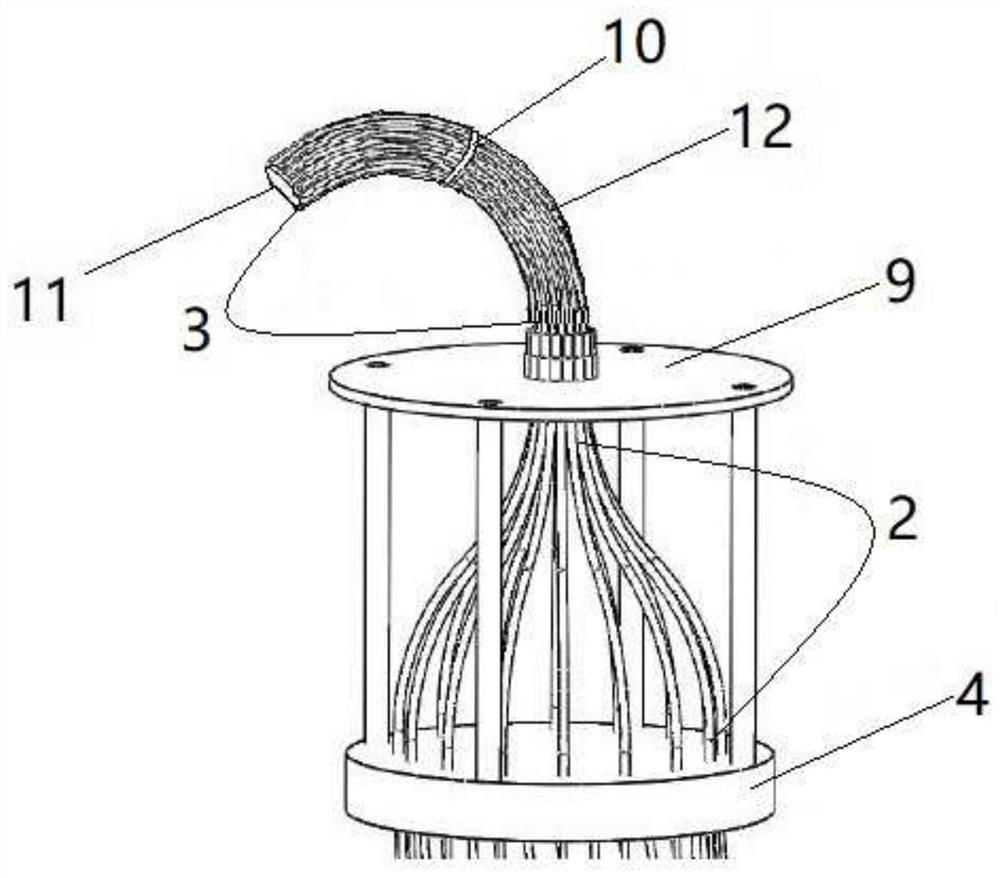

Examples

Embodiment approach

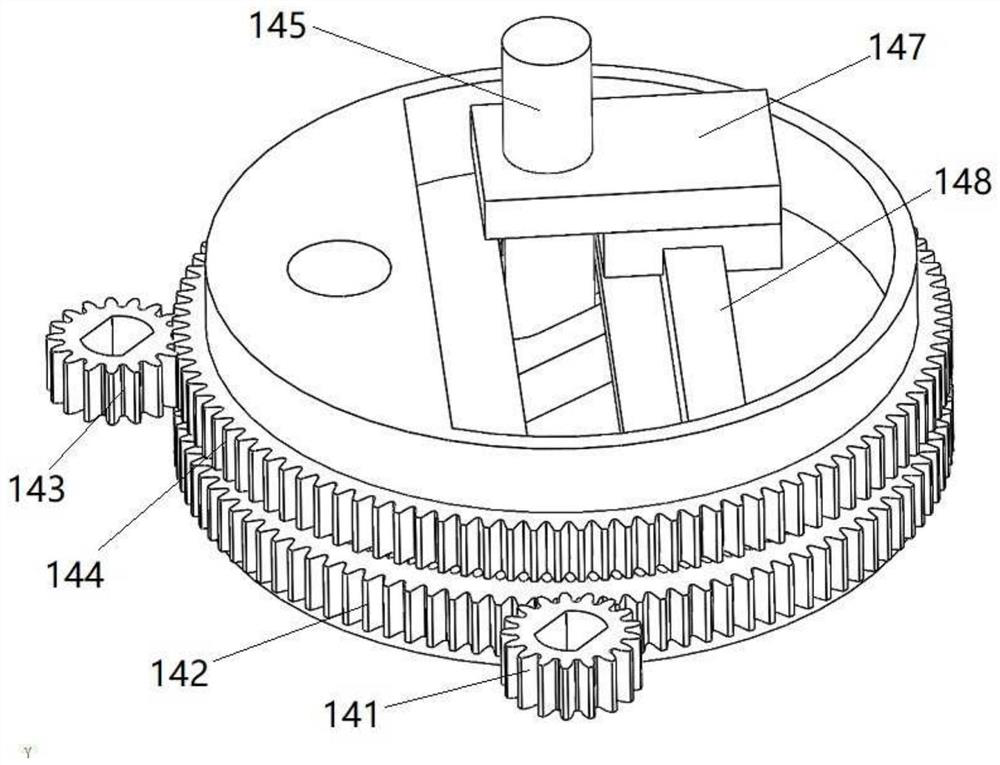

[0083] According to one embodiment of the present invention, as shown in the figure, the gear chute mechanism includes: a first driving gear 141, a first driven gear 142, a second driving gear 143, a second driven gear 144, a sliding pin 145, Connecting rod 146, slide block 147. The first driven gear 142 and the second driven gear 144 are arranged coaxially, and both can rotate relative to each other. The first driving gear 141 meshes with the first driven gear 142 . One end of the connecting rod 146 is provided with a first sliding slot 1461 , and the outer peripheral surface 1462 of the other end is tooth-shaped for meshing with the teeth of the inner ring of the first driven gear 142 . The rotating shaft 149 fixedly connected with the connecting rod 146 moves through the eccentric position of the second driven gear 144 . The second driven gear 144 is provided with a second chute 1441 along the center line of the diameter of the disk surface, and a slide rail 148 parallel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com