Desulfurization tower bottom flushing and stirring device

The technology of a stirring device and desulfurization tower is applied in the field of desulfurization tower flushing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

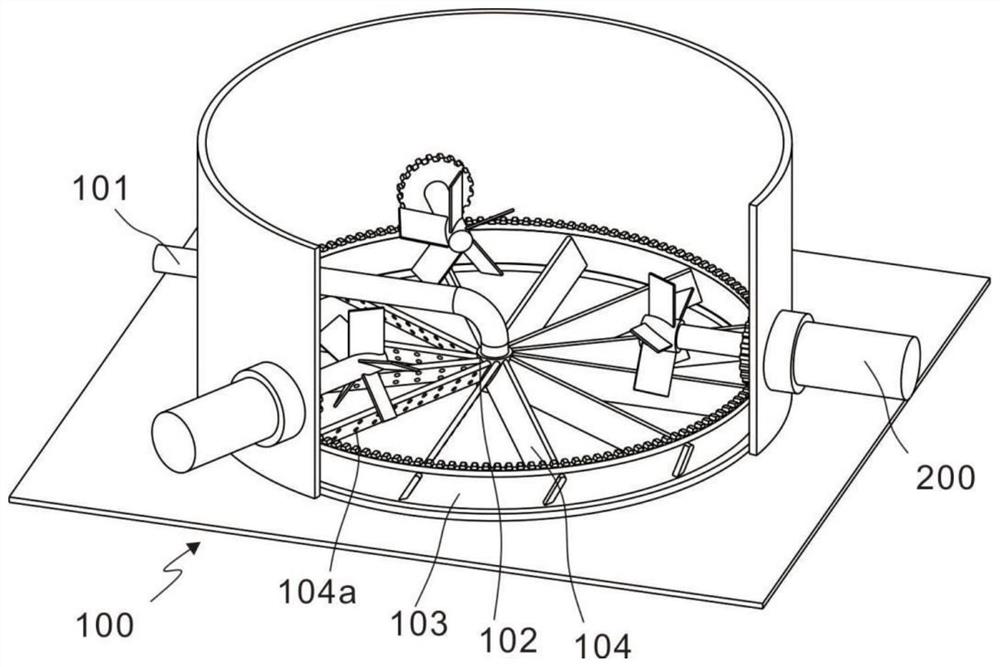

Embodiment 1

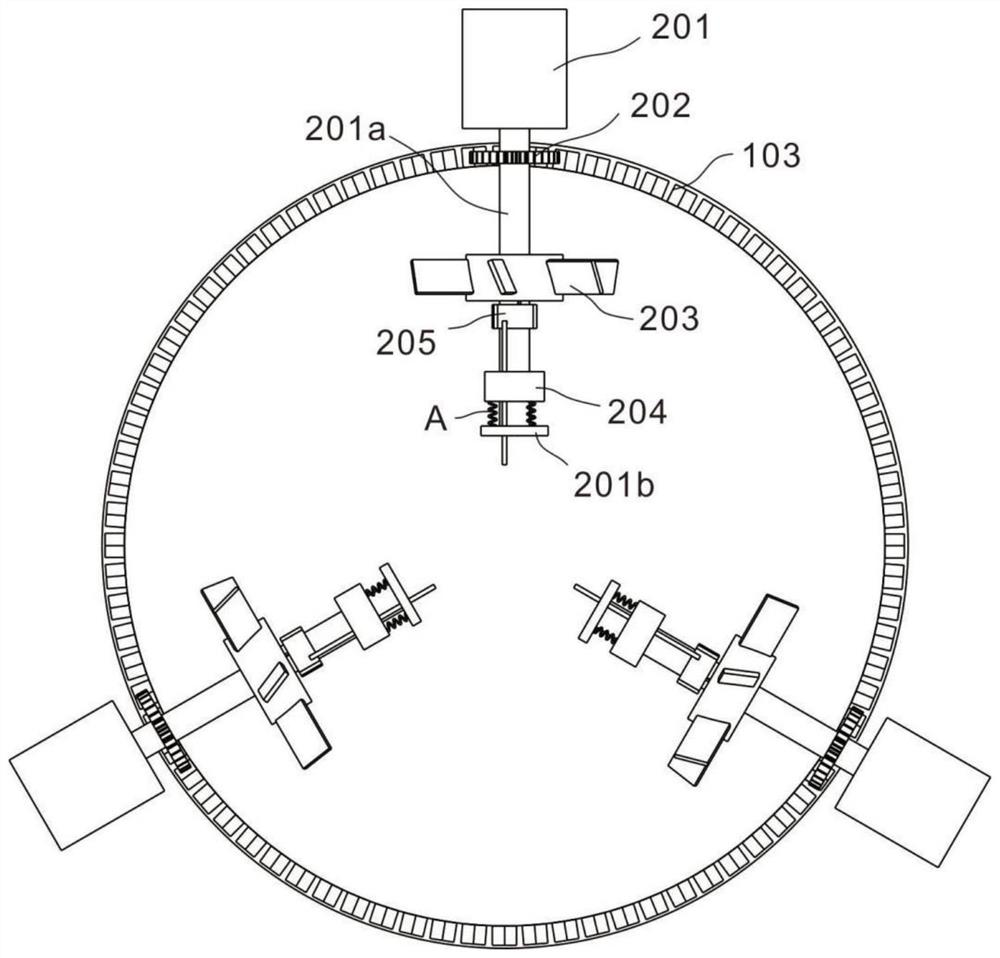

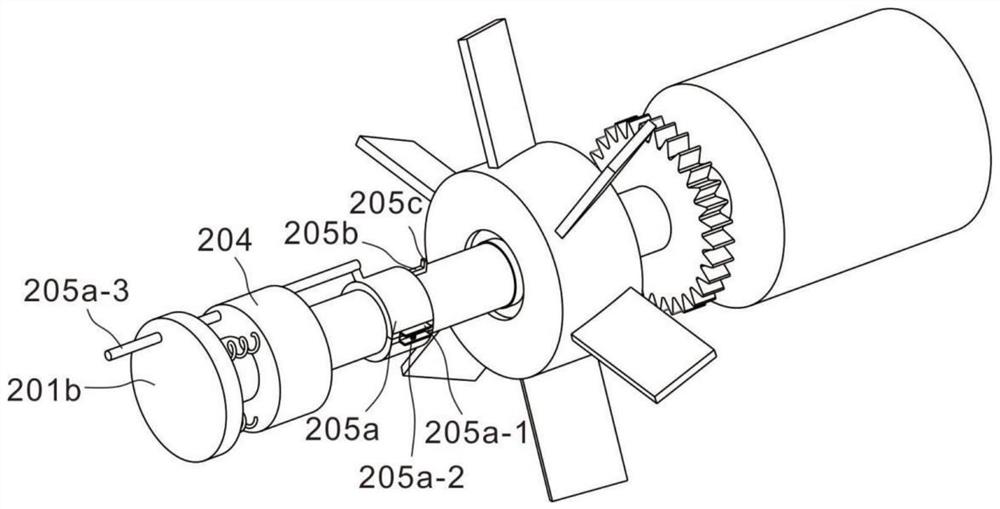

[0029] refer to Figure 1~6 , is the first embodiment of the present invention, which provides a flushing and stirring device at the bottom of a desulfurization tower, including a flushing assembly 100 and a stirring assembly 200, both of which are installed at the bottom of the desulfurization tower; The 100 can wash and scrape the bottom of the desulfurization tower, and the agitation of the agitating component 200 can reduce the gypsum deposits in the slurry tank.

[0030] The flushing assembly 100 includes a water inlet pipe 101, a shaft pipe 102, a ring gear 103 and a scraper 104. The shaft pipe 102 and the ring gear 103 are installed at the bottom of the desulfurization tower, and the shaft pipe 102 is located in the ring gear 103 and coaxial with the ring gear 103. The scraper 104 is located between the shaft tube 102 and the ring gear 103 and is fixedly connected to the shaft tube 102 and the ring gear 103. The scraper 104 has a long strip structure and is inclined. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com