Fabricated retaining wall steam curing system

A prefabricated and retaining wall technology, applied in buildings, artificial islands, ceramic molding machines, etc., can solve the problems of long demoulding time and slow strength increase, and achieve short demoulding time, high steam curing efficiency, and improved steam curing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

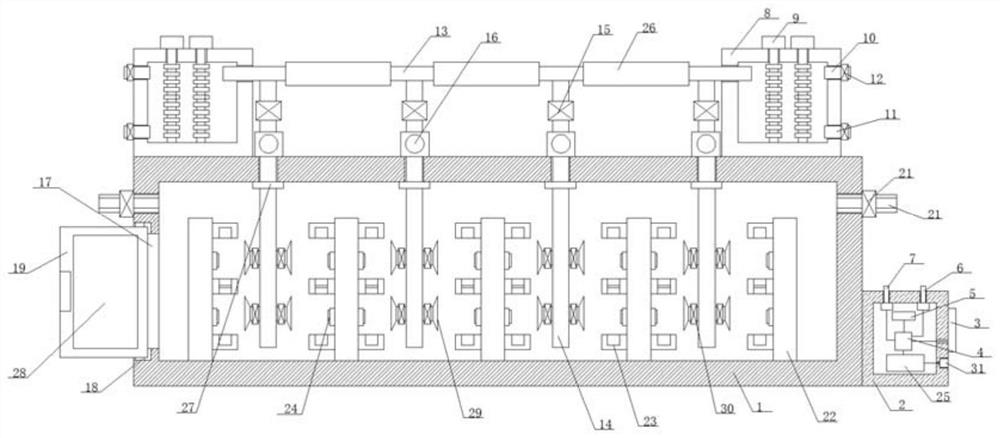

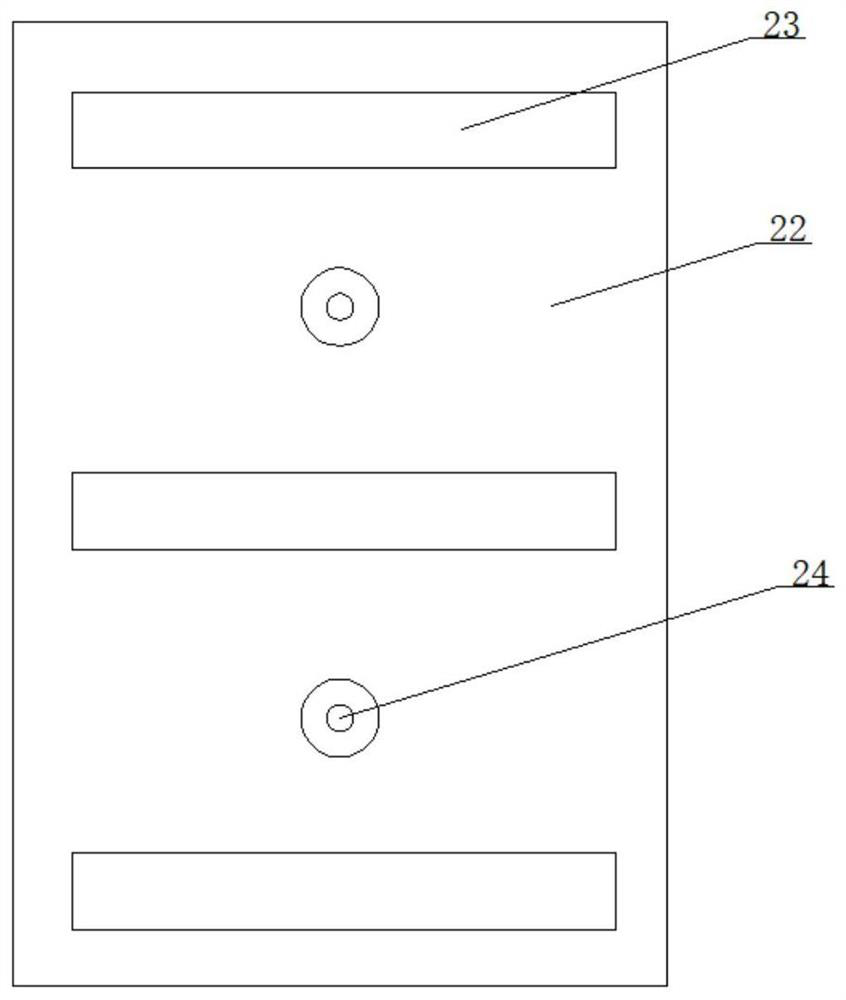

[0032] refer to Figure 1-4 , a prefabricated retaining wall steaming system, including a steaming room 1 and a control cabinet 2, the outer wall of the control cabinet 2 is fixedly connected with a touch screen 3, which is convenient for inputting control commands, and the control cabinet 2 is equipped with a power supply 25 and a controller 4 , memory 5, signal receiver 6 and signal transmitter 7, and the outer wall of control cabinet 2 is fixedly inserted with power connector 31, and the input end of power connector 31 is connected with the input end of power supply 25, is convenient to charge power supply 25, control Device 4 is a PLC controller;

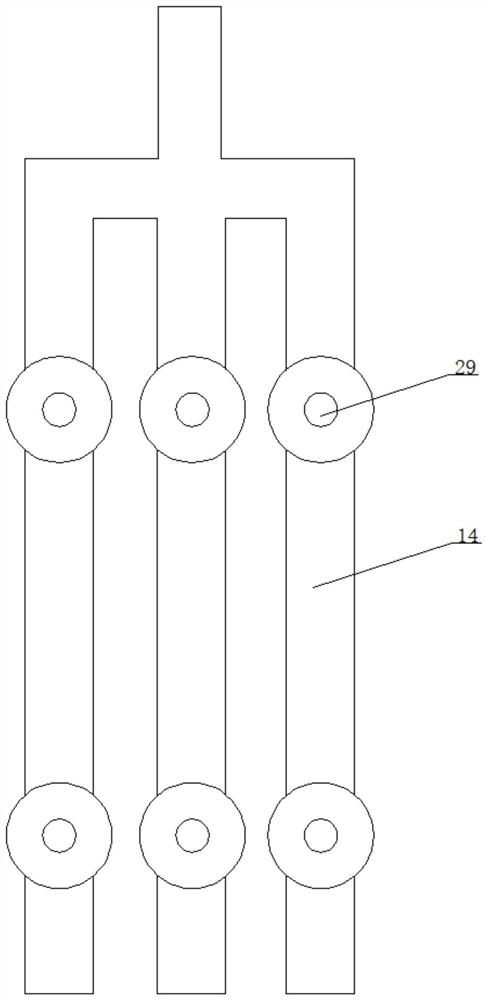

[0033] In the present invention, the top of the steaming chamber 1 is fixedly connected with two symmetrically arranged heating boxes 8, which are used to set clear water and generate steam by heating with a heating rod 9, and a heating rod 9 is fixedly inserted in the heating box 8 for heating. Clean water is heated, and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com