Intelligent notching device and method for soft rubber product

A product and soft rubber technology, which is applied in the field of intelligent incision devices for soft rubber products, can solve the problems of low production efficiency and shortened service life of the lower mold, and achieve the effects of improving production efficiency, thin molding thickness and reducing opening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

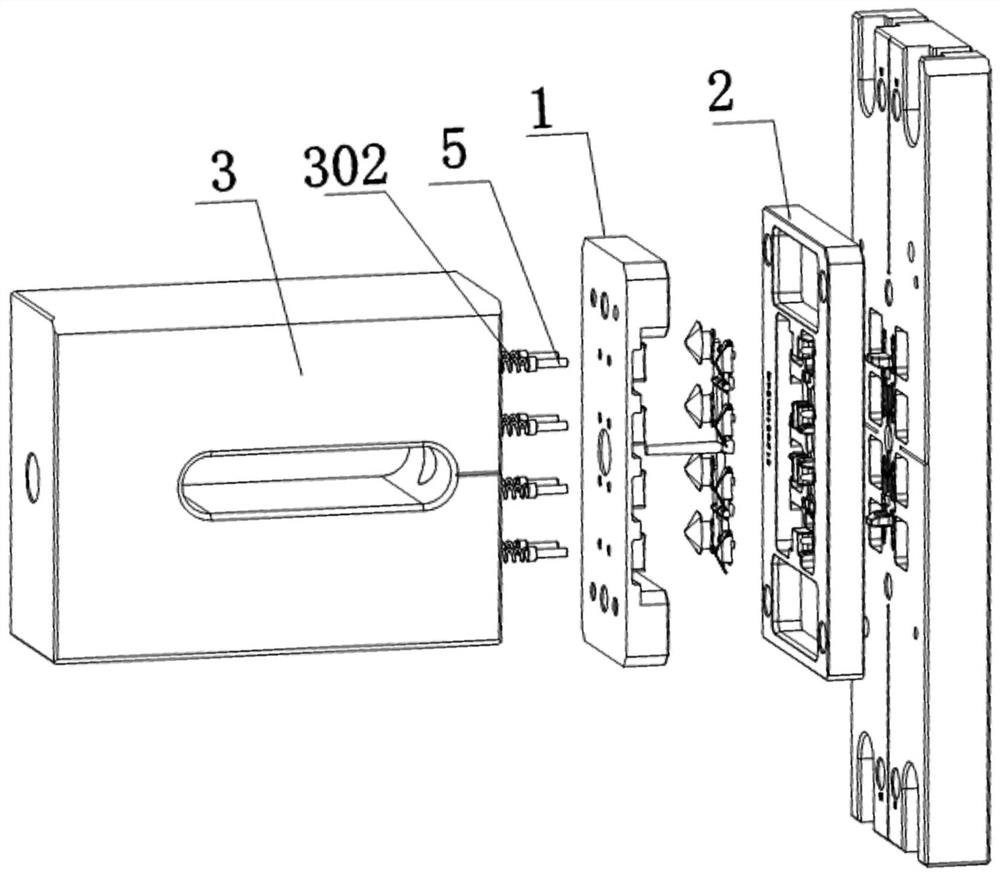

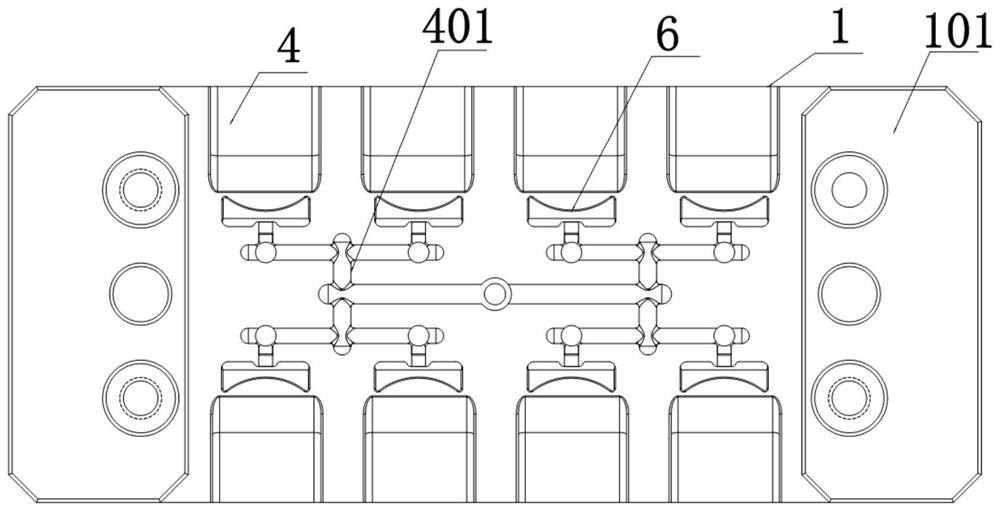

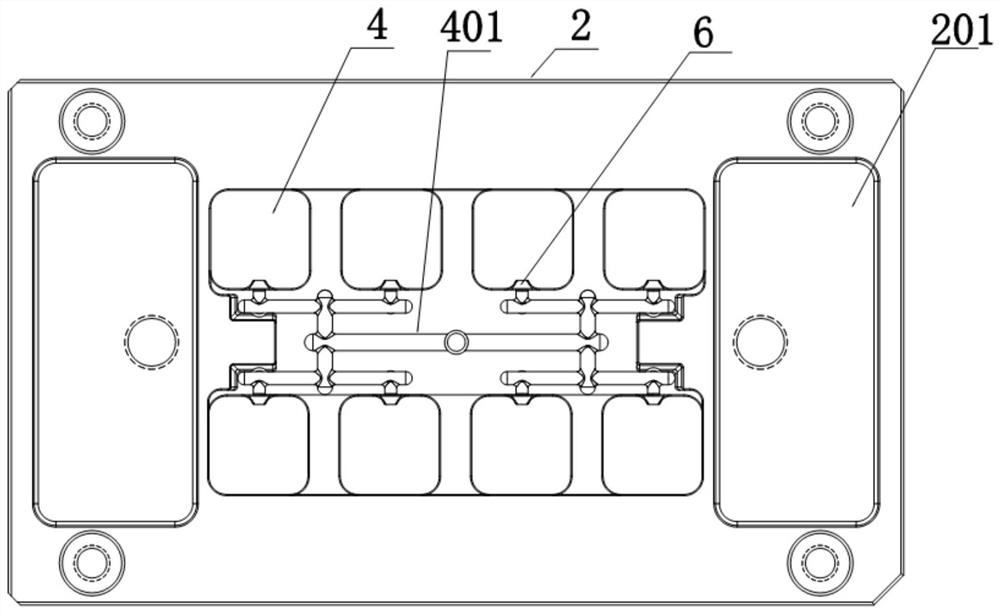

[0031] like Figure 1-4As shown, an intelligent incision device for soft rubber products includes an upper mold 1, the right side of the upper mold 1 is sealed and fitted with a lower mold 2, the upper mold 1 is fixedly connected to the mold fixing plate 3, and the lower mold 2 is fixedly connected to the fixing plate, Both the upper mold 1 and the middle part of the lower mold 2 are provided with a plurality of product mold grooves 4, and the product mold grooves 4 are connected through the flow channel 401, and the joints between the product mold groove 4 and the flow channel 401 are provided with raised cutters. The protruding cutter 6 is set to make the thickness of the connection between the product cavity 4 and the flow channel 401 thin during the injection molding process, so as to facilitate the manual separation of the waste rubber and the product in the later stage; the flow channel 401 includes an I-shaped main flow Channel 4011, the I-shaped main channel 4011 commu...

Embodiment 2

[0039] Based on the above-mentioned embodiment 1, the above-mentioned device can only achieve injection molding, demoulding, and the separation point of the pre-fabricated product and waste material, but cannot completely separate the product and waste material, and due to the convex setting of the cutter, it will cause a problem in the injection process. , leading to the increase of time for injecting soft rubber into the product cavity 4, resulting in low production efficiency. At the same time, in the prior art, when using a telescopic cutter to completely cut and separate the product and waste, it often leads to burrs on the edge of the cut product , and the surface of the cutter after cutting carries a part of waste rubber particles, so that in the subsequent new product processing and manufacturing process, the product is mixed with waste particles, which affects the quality of the produced product. In order to solve the above problems, the inventor made further improvemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com