Landfill leachate treatment device and process based on enhanced Fenton oxidation method

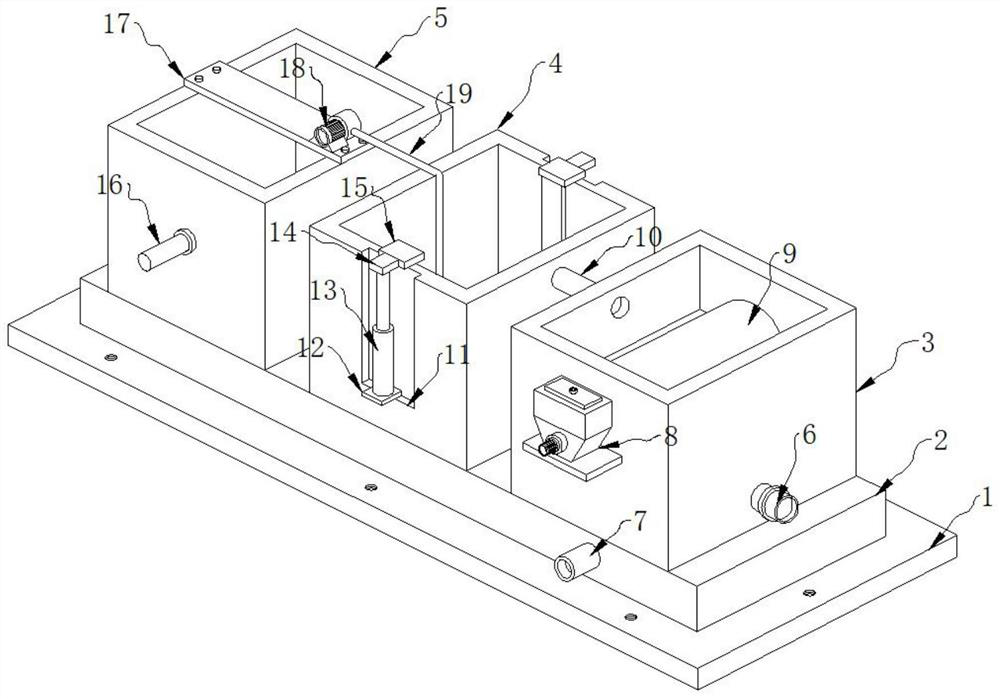

A landfill leachate and treatment device technology, which is applied in the field of landfill leachate treatment devices based on the enhanced Fenton oxidation method, can solve the problems of difficult treatment, cleaning of filter equipment, inconvenient use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

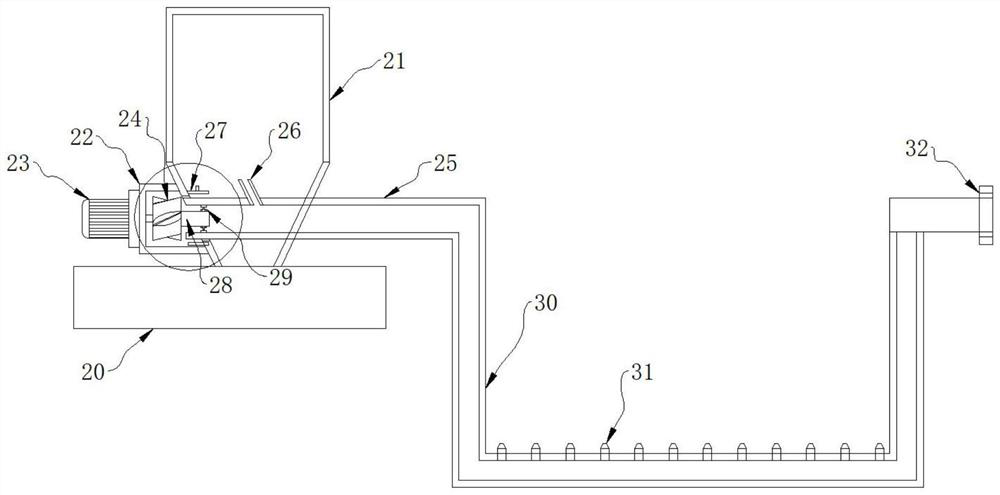

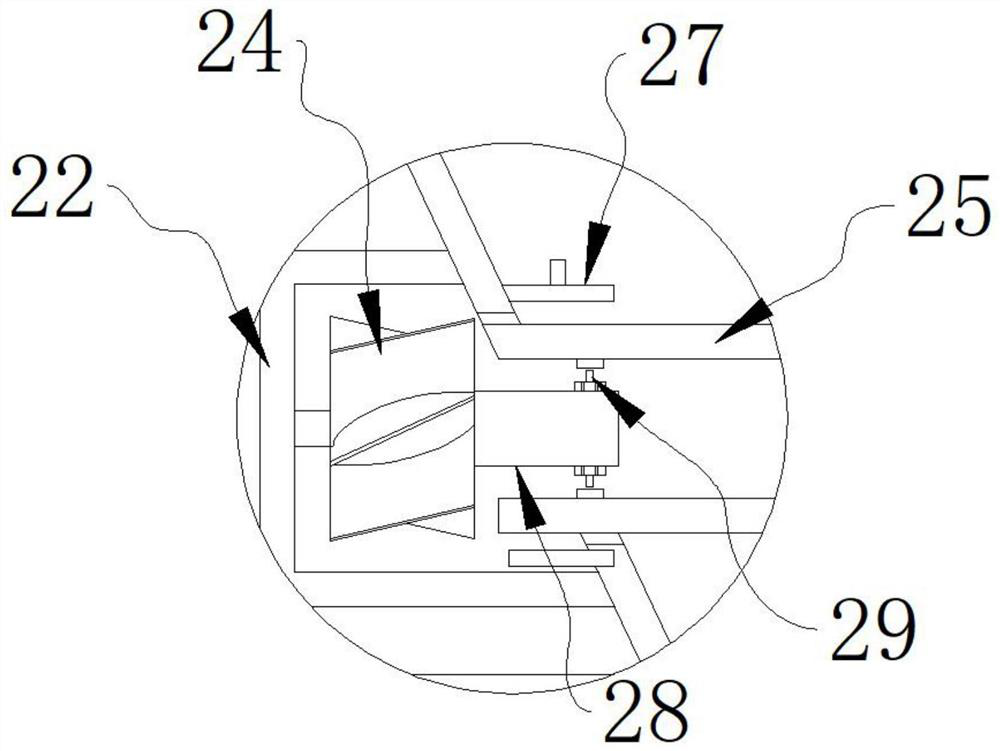

[0034] As a preferred embodiment of the present invention, the feeding device 8 includes a limit seat 20, the limit seat 20 is fixed on the sedimentation tank 3, and a feed box 21 is installed on the limit seat 20, so One side of the feed box 21 is fixed with a mounting portion 22, a motor one 23 is mounted on the mounting portion 22, a fan blade 24 is mounted on the motor one 23, and the fan blade 24 is installed in the inside of the mounting portion 22 , a rotating rod 28 is installed on the fan blade 24 .

[0035] As a preferred embodiment of the present invention, the inside of the feed box 21 is equipped with an electromagnetic coil 27 and a pipeline 25, the pipeline 25 is installed on the feed box 21 through a bearing, and an inclined pipe is installed on the pipeline 25 26. A fixing device 29 is installed on the rotating rod 28, and tooth sockets are formed on the inner wall of the pipeline 25.

[0036] As a preferred embodiment of the present invention, the fixing dev...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap