Self-cleaning chloroplast extractor for experiments

A chloroplast, experimental technology, applied in the field of experimental instruments, can solve the problems that affect the amount of chloroplast extraction, take a long time, process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

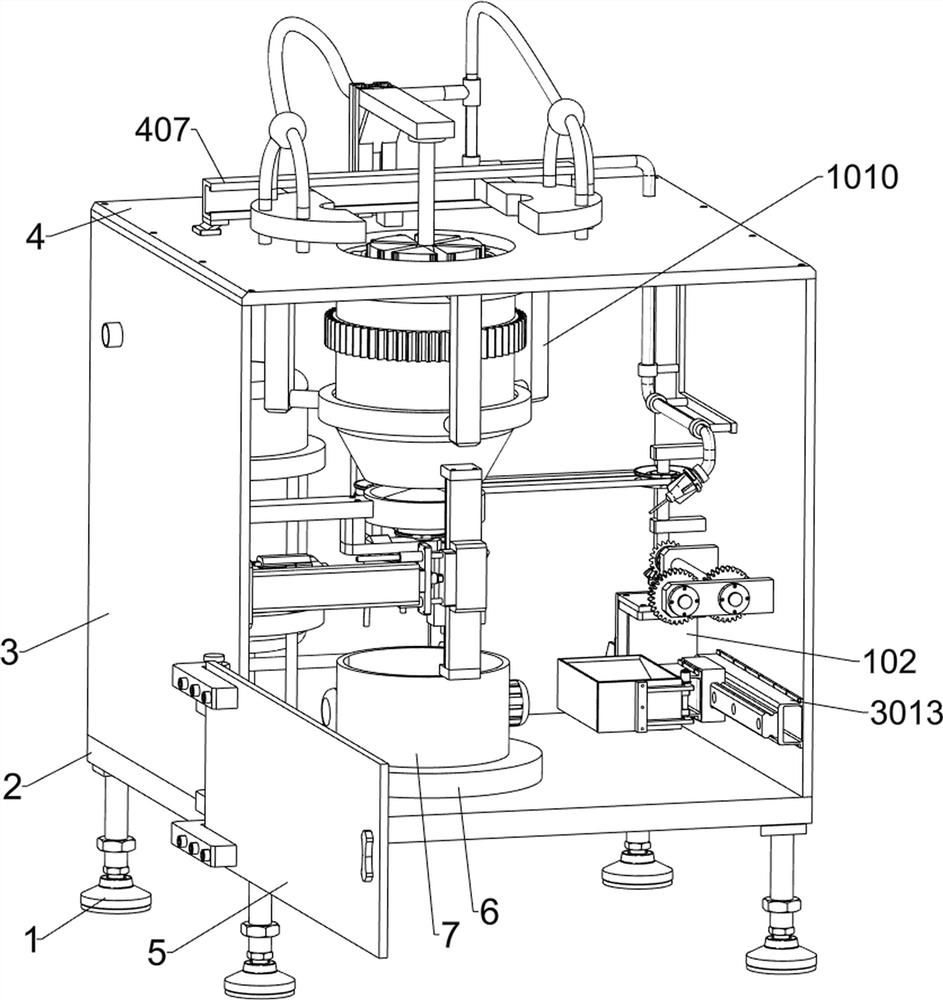

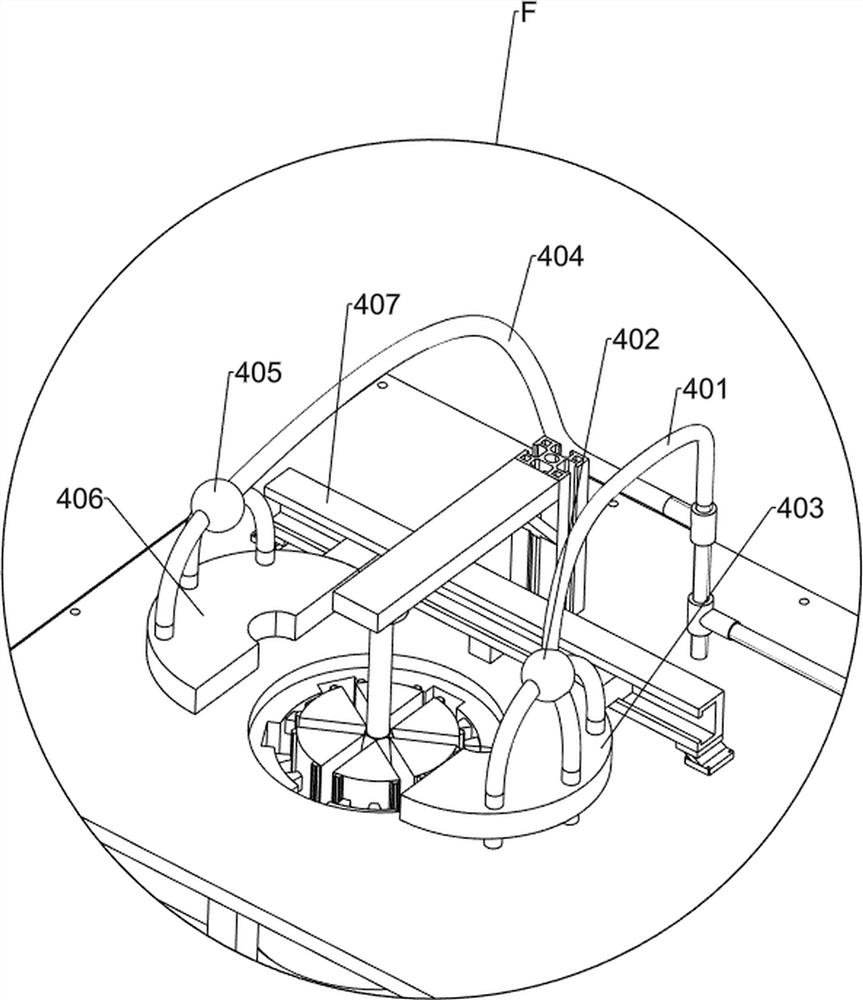

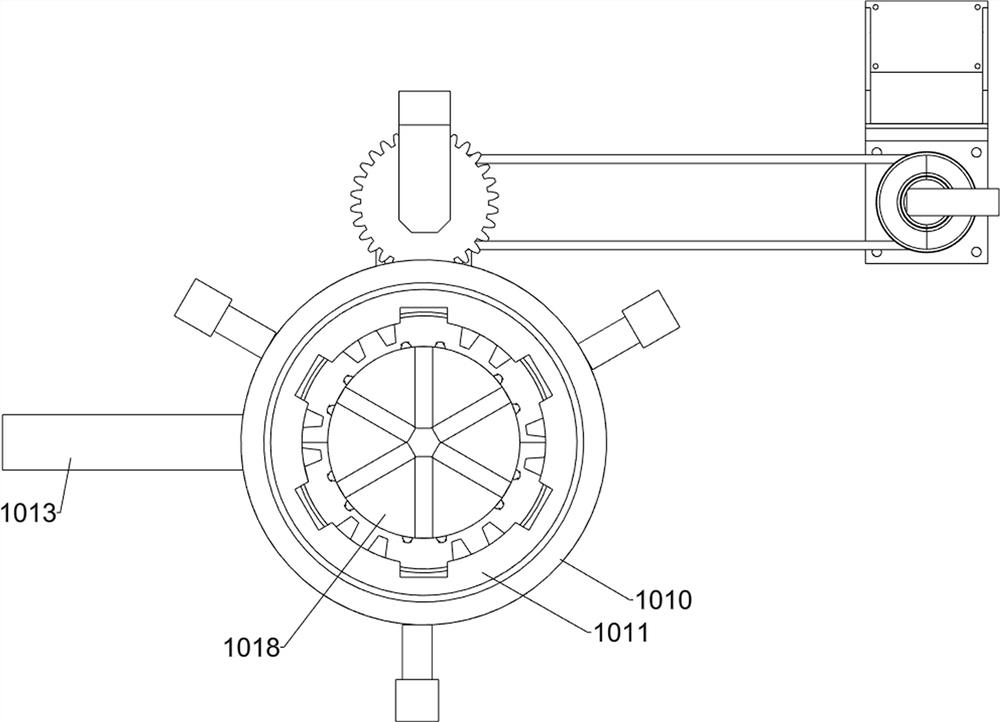

[0035] A self-cleaning type experimental chloroplast extractor, such as Figure 1-3 As shown, it includes anti-skid foot pad 1, bottom plate 2, shell 3, top plate 4, airtight door 5, fixed seat 6, beaker 7, blade treatment system and waste residue treatment system; the four corners of the bottom surface of bottom plate 2 are respectively provided with a set of anti-skid Foot pad 1; shell 3 is affixed above bottom plate 2; fixed seat 6 is fixed in the middle above bottom plate 2; blade treatment system for crushing and grinding experimental leaves is fixed on the right side above bottom plate 2; top plate is affixed above shell 3 4; the right side of the bottom of the shell 3 is fixedly connected with a waste residue treatment system for processing the waste residue after the extraction of chloroplasts; the top plate 4 is connected to the blade processing system; the top plate 4 is connected to the waste residue treatment system; the bottom plate 2 is connected to the waste resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com