Aluminum alloy and preparation method thereof

A technology for aluminum alloy and aluminum alloy ingots, applied in the field of alloy materials, can solve the problem that aluminum alloys are difficult to take into account mechanical properties and elongation, and achieve the effects of avoiding high temperature blistering and deformation problems, simple heat treatment steps, and low equipment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] Another embodiment of the present invention provides a method for preparing an aluminum alloy as described above, comprising the following steps:

[0055] Weigh Al agent, Si agent, Mn agent, Cu agent, Zn agent, Ga agent, La agent, part of Fe agent and Ca agent in required proportions according to the ratio of elements in the aluminum alloy, and add them to the melting furnace for smelting , to get the melt;

[0056] Refining the melt with a refining agent, removing the Ca agent, introducing an inert gas, and removing the scum;

[0057] Weigh the Mg agent of the required proportion and number, and add it to the smelting furnace;

[0058] Respectively weigh the Sr agent, Cr agent, Mo agent, Ti agent and the remaining Fe agent in required proportions for modification, degassing, and casting to obtain an aluminum alloy ingot;

[0059] Die-casting the aluminum alloy ingot.

[0060] In the present invention, Al agent, Si agent, Mn agent, Cu agent, Zn agent, Ga agent, La ag...

Embodiment 1

[0092] This example is used to illustrate the aluminum alloy disclosed in the present invention and its preparation method, including the following steps:

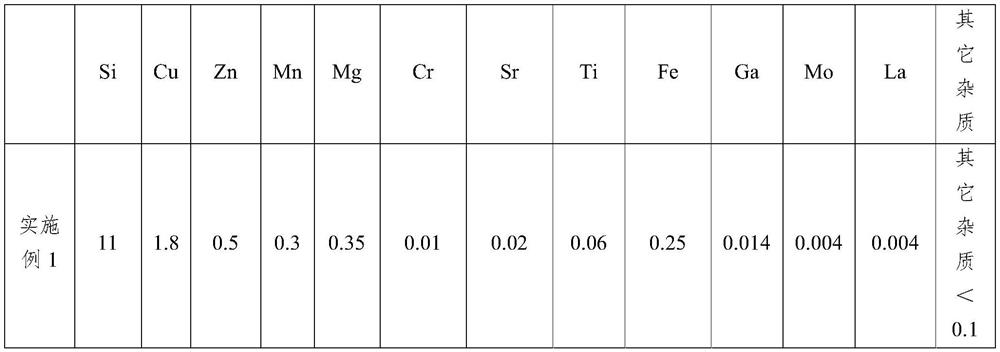

[0093] As shown in Table 1, the composition of the aluminum alloy is calculated by mass content: the content of Si is 11%, the content of Cu is 1.8%, the content of Zn is 0.5%, the content of Mn is 0.3%, and the content of Mg is 0.35%. The content of Cr is 0.01%, the content of Sr is 0.02%, the content of Ti is 0.06%, the content of Fe is 0.25%, the content of Ga is 0.014%, the content of Mo is 0.004%, and the content of La is 0.004%, according to The mass content of the above-mentioned aluminum alloy composition requires the mass of various intermediate alloys or metal elements, the balance is Al and other elements, and the total amount of other elements is less than 0.1%, and it is added and operated according to the following steps:

[0094] Step 1. When the furnace temperature is 200°C-300°C, add pure aluminum;

[009...

Embodiment 2-28

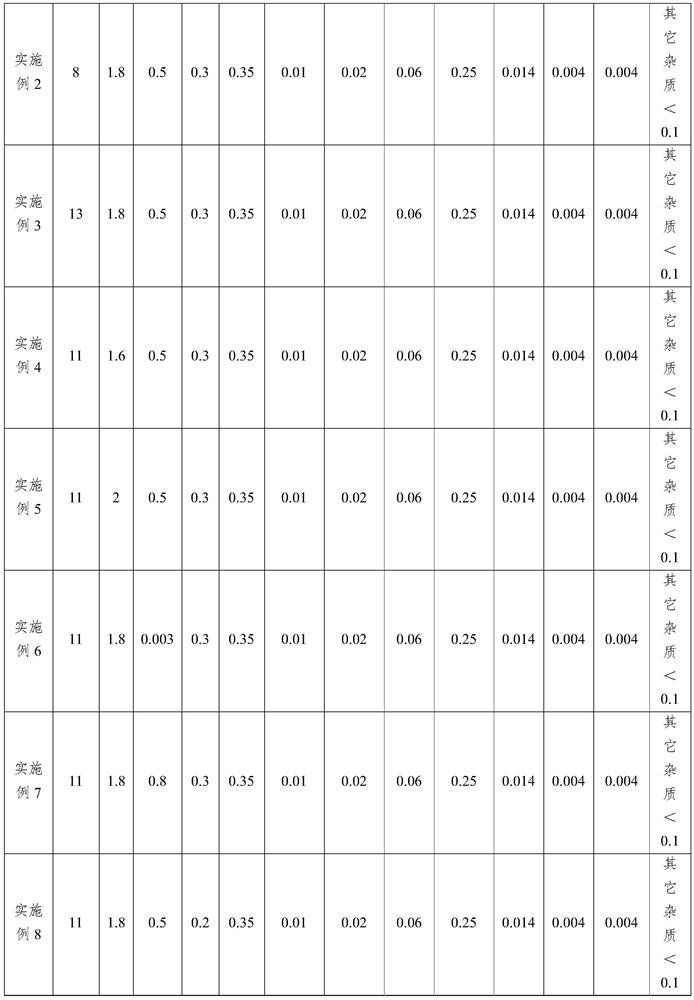

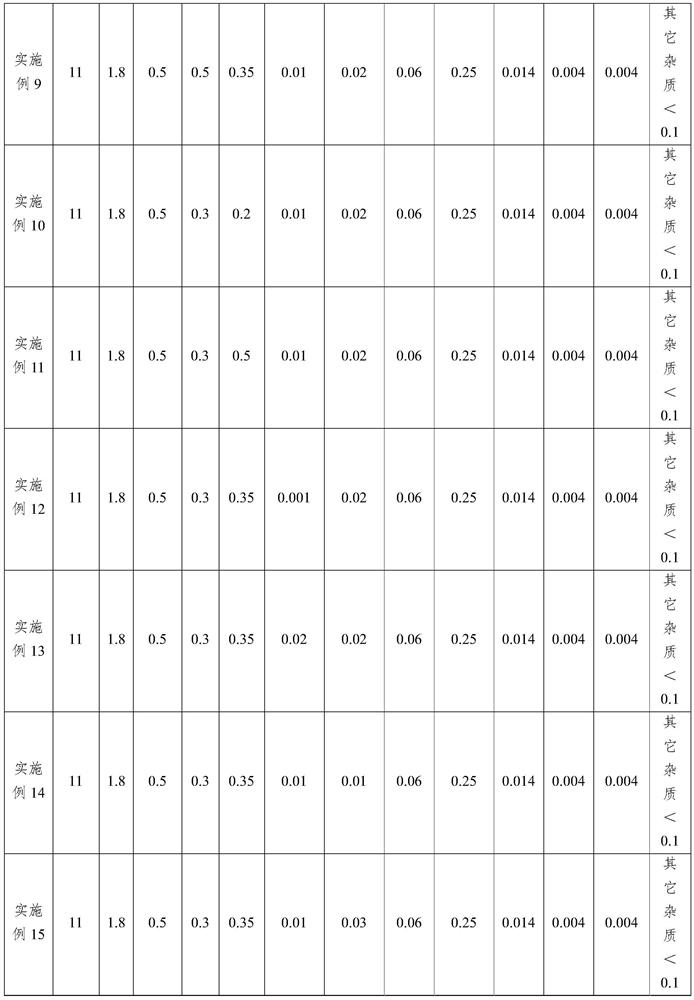

[0104] Examples 2-28 are used to illustrate the aluminum alloy disclosed in the present invention and its preparation method, including most of the operation steps in Example 1, the differences are:

[0105] The aluminum alloy compositions shown in Examples 2-28 in Table 1 were used, and other operating steps were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com