Rapid bucket crumple connecting device and method capable of detecting overexcavation offset distance

A connecting device and bucket technology, which is applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of criminal punishment, economic loss, and excavators without anti-over-excavation equipment, so as to achieve fast response and ensure rapid collapse The effect of contraction and structural connection is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

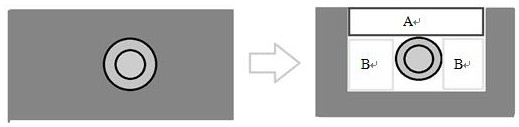

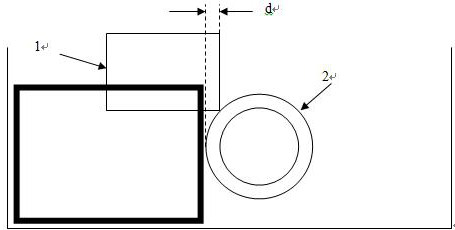

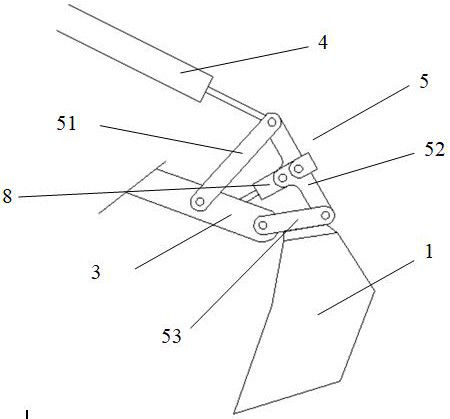

[0047] Figure 1-4 The illustrated embodiment shows the bucket collapse connection structure of Embodiment 1. Such as image 3As shown, it is a schematic diagram of the connection structure of the bucket 1 in this embodiment, which includes an excavator telescopic arm 3, and the telescopic arm 3 is arranged on the front part of the excavator chassis. The excavator chassis can move in the horizontal and vertical directions to adjust the position. The bucket 1 is connected to the telescopic arm 3 through the collapse connecting rod group 5 . At the same time, a hydraulic cylinder 4 is also provided for driving the rotation of the bucket. The cylinder body end of the hydraulic cylinder is connected to the telescopic arm 3 (not shown), and the other end (piston rod end) is hinged to the collapse connecting rod group.

[0048] The collapse connecting rod set includes a connecting rod 51 , a foldable crushing rod 52 and a connecting rod 53 . One end of the connecting rod 51 is h...

Embodiment 2

[0052] Embodiment 2 has the same structure of the crushing link group as in Embodiment 1, and simultaneously, its telescopic pin 523 is an elastic explosion telescopic pin, and the specific structure of the telescopic pin is as follows: Figure 5 shown.

[0053] The telescoping pin has a seat portion, the seat portion has a B end and a C end, and a hollow A region at the B end and the C end. The elastic explosion telescopic pin is fixedly installed on the crushing arm 522 through the B end of the base body, and the movable hinge point 524 of the two crushing arms is located in the A region. The pin body has a movable pin shaft 5231 passing through the hole of the living hinge point 524 to connect the two crush arms. The pin shaft 5231 is provided with two locking grooves, and in the fixed state, the adjustable spring snap beads 5232 on the B end and the C end of the seat body are engaged in the locking grooves to realize the fixing of the pin shaft 5231. The right end of pin...

Embodiment 3

[0057] Embodiment 3 has the same crushing link group structure and elastic explosion telescopic pin structure as the above embodiment. In addition, it also has a collapse detection control system and a collapse orientation structure.

[0058] The collapse detection and control system includes a planar force sensor 6 arranged at the structural connection of the bucket and the collapse connecting rod group. The planar force sensor 6 is specifically arranged at both ends of the hinge shaft connecting the connecting rod 53 and the collapsible connecting rod 52 , and can detect the horizontal and vertical forces on the bucket 1 . The system also includes a computing unit 7 , whose input end is connected to the planar force sensor 6 , and whose output end is connected to the signal line of the elastic explosion telescopic pin 523 . A calibrated bucket force threshold is pre-stored in the calculation unit 7 , and the planar force sensor 6 is connected to the calculation unit 7 . Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com