Flame-retardant high-strength wood-plastic profile and preparation method thereof

A wood-plastic profile, high-strength technology, used in building types, other home appliances, fences, etc., can solve the problems of wood-plastic profiles not having a production date recording structure and inconvenient warning methods, to improve hardness and rigidity. The effect of flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

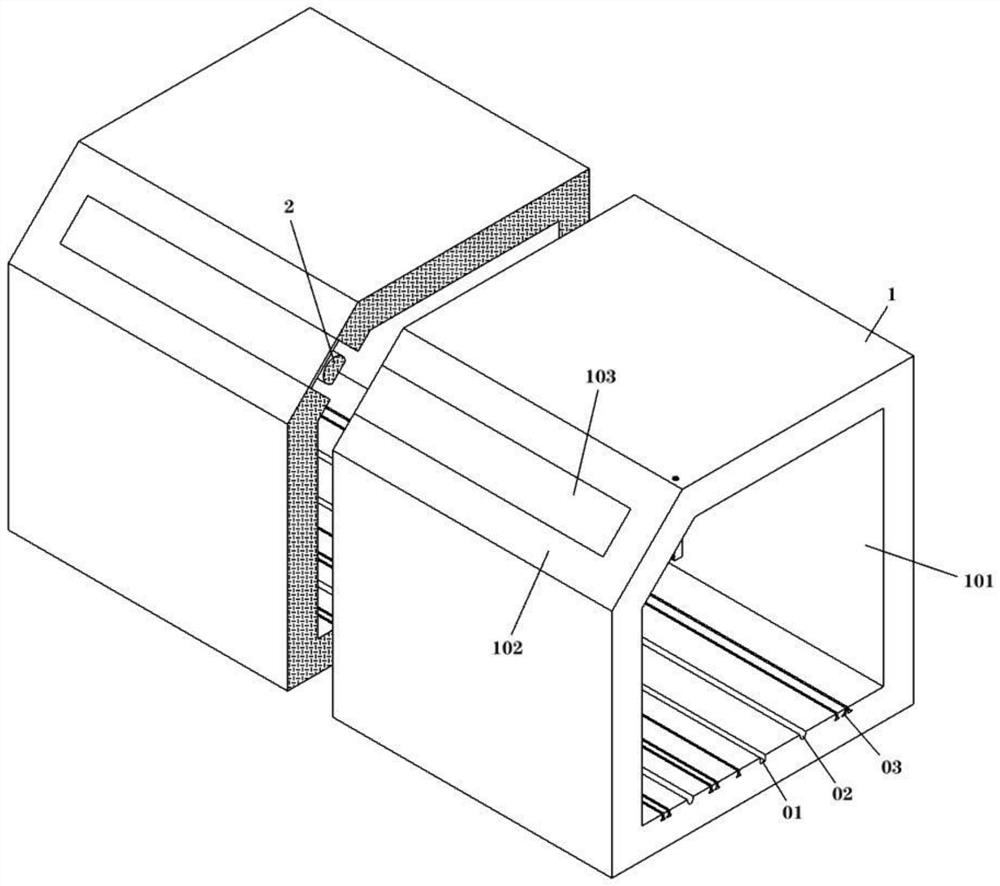

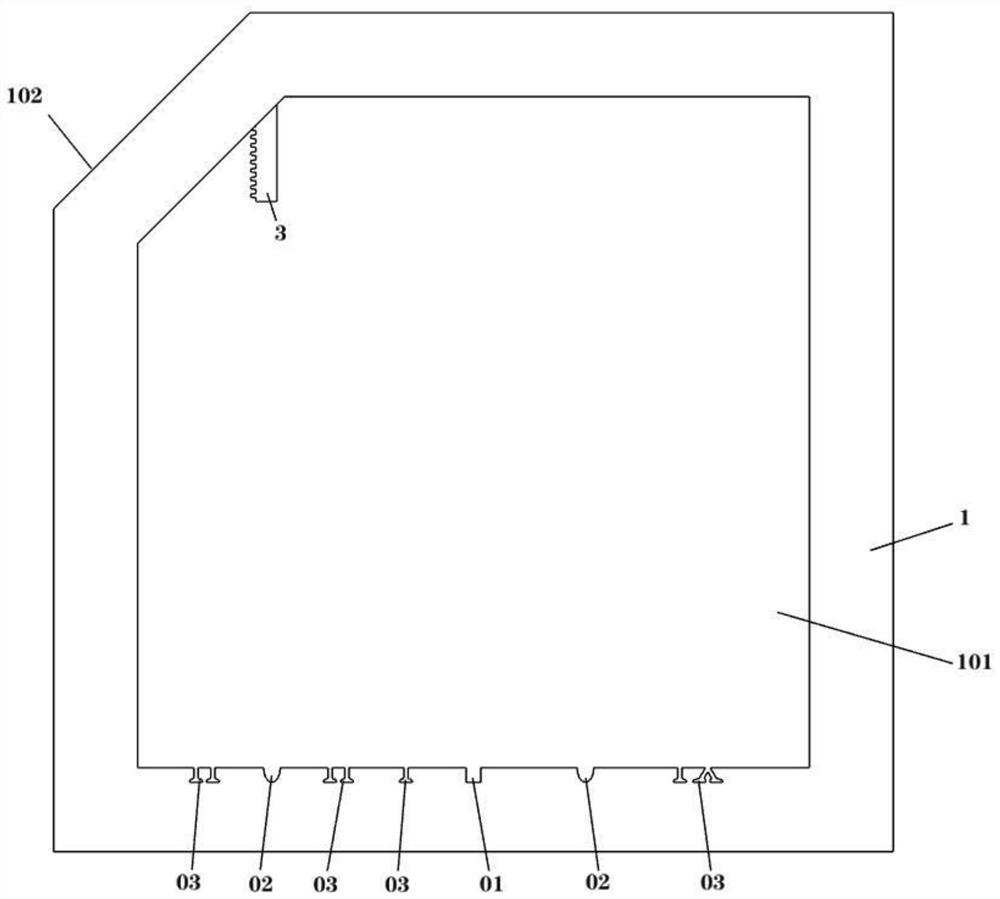

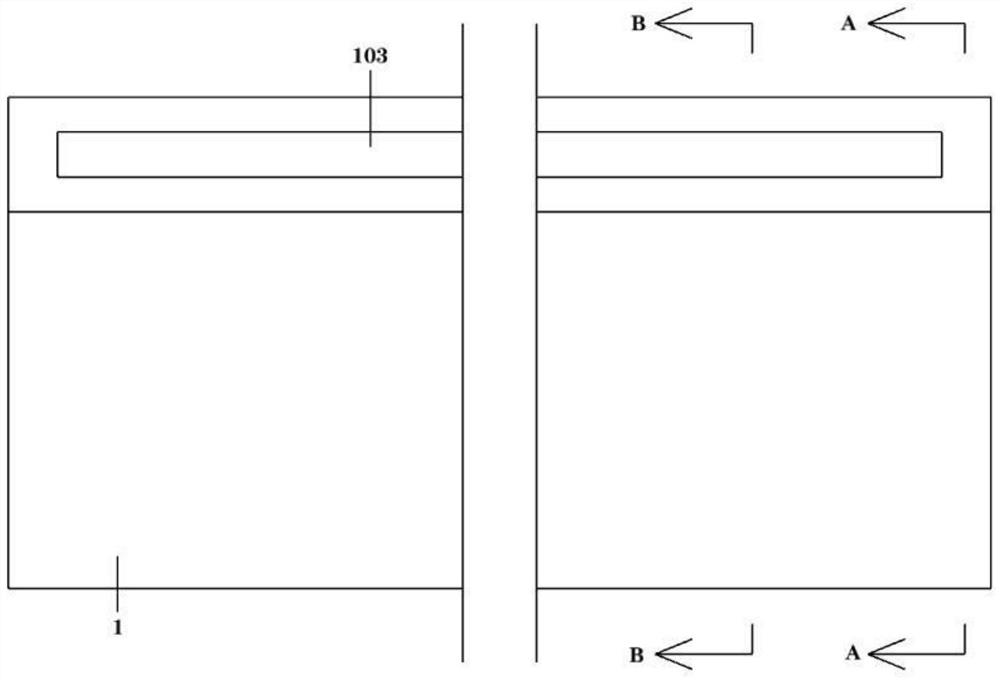

[0047] as attached figure 1 To attach Figure 11 Shown:

[0048] The invention provides a flame-retardant high-strength wood-plastic profile and a preparation method thereof, comprising: a wood-plastic profile main body 1, a longitudinal section of the wood-plastic profile main body 1 having a square structure, and a gap between the left end surface and the top surface of the wood-plastic profile main body 1 There is an inclined surface 102, and the angle between the inclined surface 102 and the bottom end surface of the wood-plastic profile main body 1 is 45 degrees; the front end surface of the wood-plastic profile main body 1 is provided with a hollow opening 101 passing through the rear end surface, and the hollow opening 101 has a square mouth structure , and there is an inclined surface structure between the left side and the top side of the inner end of the hollow opening 101, and the inclined surface structure is parallel to the inclined surface 102; the middle part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com