Pneumatic valve air source redundancy device

A technology of pneumatic valves and redundant devices, applied in the direction of valve devices, valve operation/release devices, valve details, etc., can solve problems such as breaking, affecting production, safety accidents, etc., and achieve the effect of eliminating hidden dangers of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

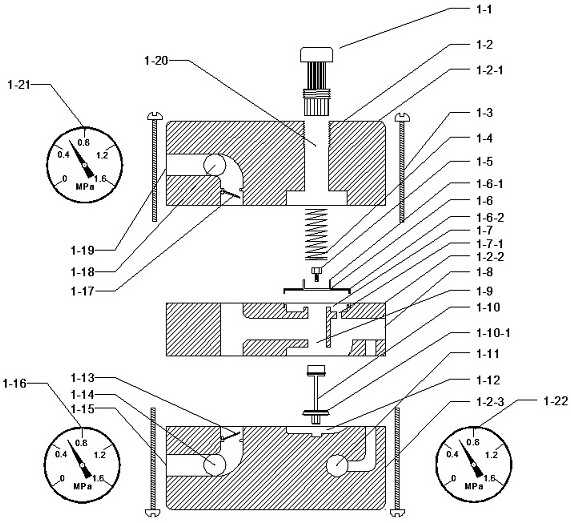

[0017] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

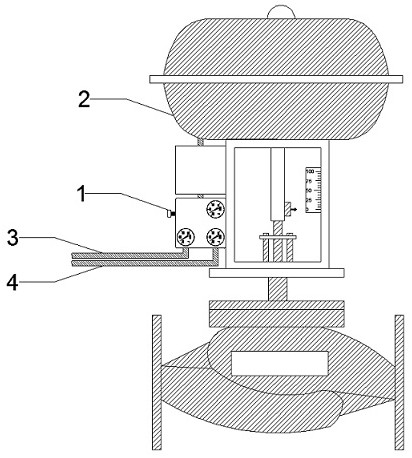

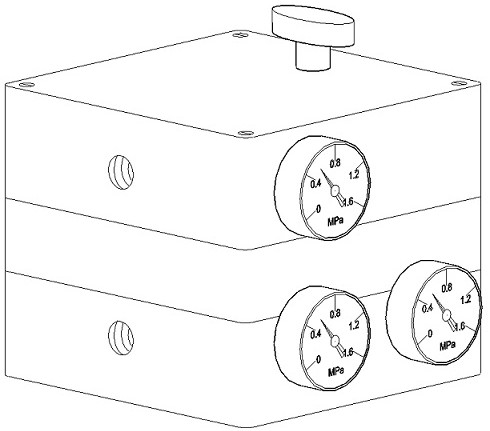

[0018] Refer to attached Figure 1-4 , a pneumatic valve air source redundant device, including pneumatic valve 2, air source A3, air source B4, pressure regulating knob 1-1, housing 1-2, pressure regulating spring 1-4, locking bolt 1-5 , Pressure regulating diaphragm 1-6, Pressure equalizing chamber 1-7, Air outlet chamber 1-8, Pressure regulating column 1-10, Intermediate chamber 1-12, Check valve B1-13, Air inlet chamber B pressure hole 14, Air intake chamber B1-15, check valve A1-17, air intake chamber A pressure hole 1-18, air intake chamber A1-19 and pressure regulating chamber 1-20, the housing 1-2 includes upper, middle, The lower three parts, the upper part of the casing is provided with a pressure regulating chamber 1-20, the pressure equalizing chamber 1-7 is formed between the upper part of the casing and the middle part of the casing, the middle c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com