Photo-thermal integrated radiator

A heat sink and photothermal technology, applied in the field of heat dissipation and cooling, can solve the problems of high surface temperature of the light source, affect the light efficiency and service life of the LED light source, limit the heat extraction capacity of the micro-groove radiator, achieve high power density, eliminate The effect of interface thermal resistance and high heat dissipation capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

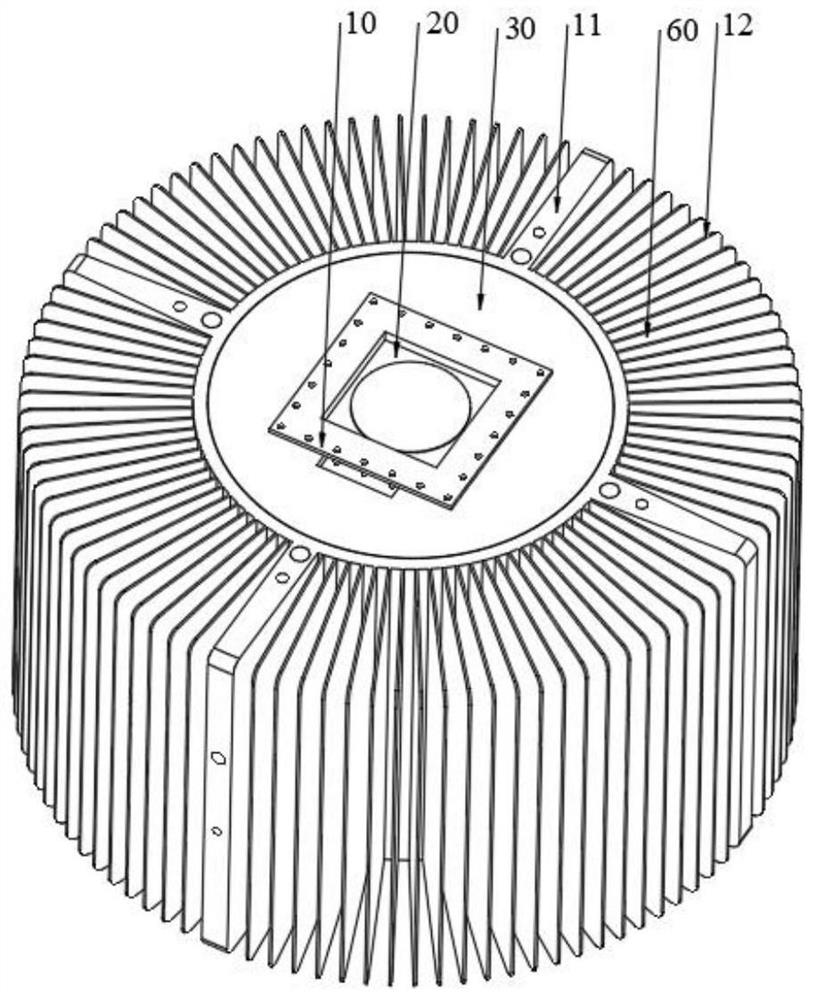

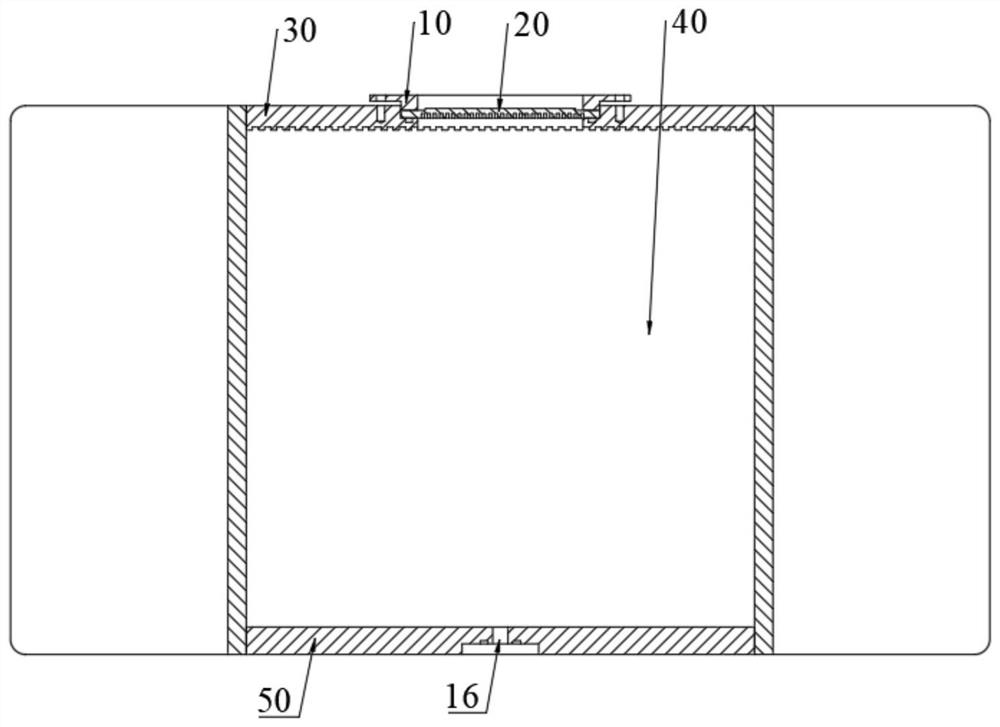

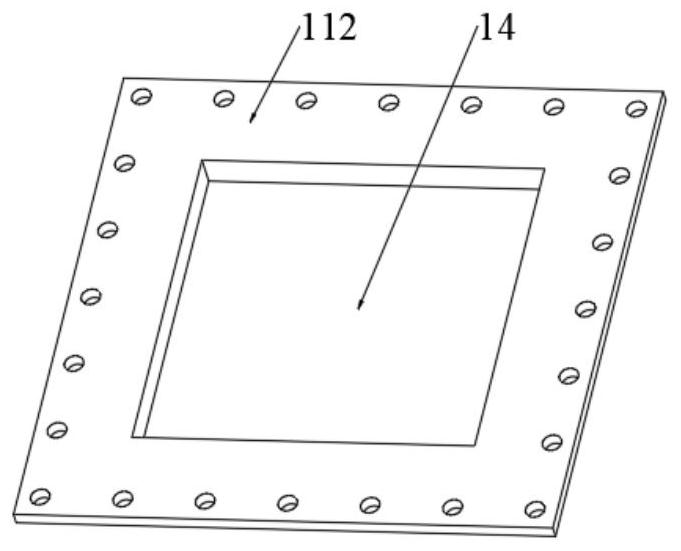

[0071] In the present disclosure, a photothermal integrated heat sink is provided, such as Figure 1 to 2As shown, the preparation method, including: the light source carrier portion, including the light source substrate 20, and the light source substrate 20 for illuminating, the light source carrier portion can export heat generated by the light source substrate 20. The heat dissipation portion includes a connecting hole, a connecting hole as a through hole, a light source carrier portion covering one end of the connecting hole, and the heat dissipation portion is used to distribute the transferred heat. The condensed cover 50 is used to cover the other end of the connection hole, form a vacuum cavity 40, and the vacuum cavity 40 is filled with a phase change treatment 15. Wherein, the phase change treatment 15 can receive the heat generated by the light source substrate and transmit it to the heat dissipation portion.

[0072] In the embodiment of the present disclosure, if Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com