A thermally conductive material with selective metal deposition and its preparation method and application

A technology of thermally conductive filler and metal, applied in the field of resin composition, to achieve the effects of prolonging the life of LED lighting, efficient heat dissipation, and eliminating interface thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

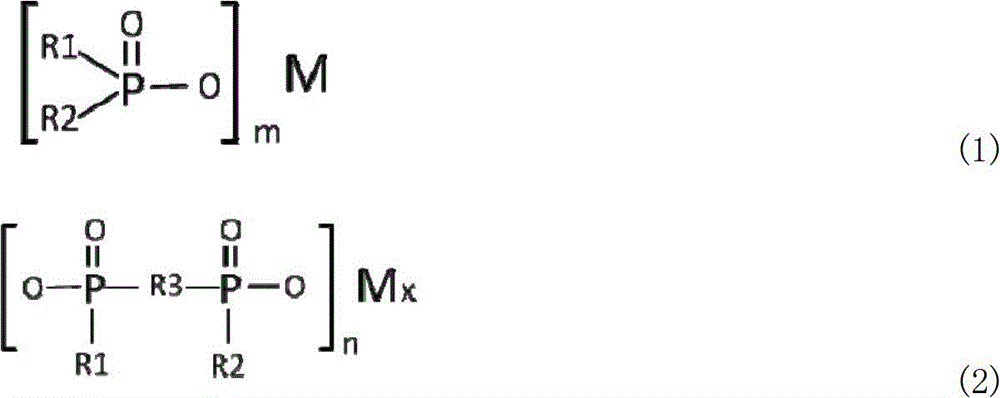

Method used

Image

Examples

preparation example Construction

[0085] The preparation method of resin composition of the present invention is as follows:

[0086]Weighing materials: 15-60wt% thermoplastic, or thermosetting plastic, or rubber, or elastomeric resin matrix; 30-70wt% thermally conductive filler; 1-10wt% metal oxide solid solution; 0-15wt% other additives ;

[0087] Mixed materials: Add resin matrix, thermal conductive filler, metal oxide solid solution, and other additives into the high-speed mixer and mix evenly;

[0088] The obtained mixed material is extruded by a twin-screw extruder, cooled, and pelletized to obtain the target product; or the obtained mixed material is loaded into a mold, and heated and pressed to obtain the target product.

[0089] The resin composition of the present invention is mainly used to make electrical and electronic components, including circuit substrates, such as electronic components, support materials for electronic components, bases for high-power LED lamps or circuit boards.

[0090] In...

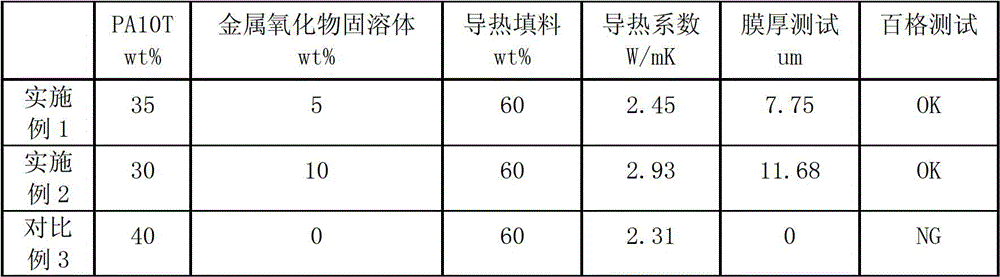

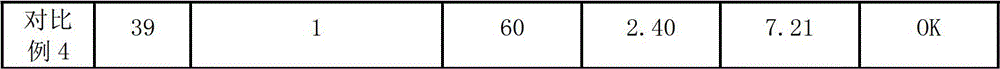

Embodiment 1

[0094] Polydecanediamide 35wt% is used as the resin matrix, 30wt% boron nitride and 20wt% magnesium oxide are used as thermal conductive fillers, 5wt% metal oxide solid solution, the solvent of the metal oxide solid solution is manganese oxide and the solute is cuprous A blend of oxides, the weight ratio of solvent to solute is 7:2, other additives are 2wt% nano-alumina and 8wt% glass fiber.

Embodiment 2

[0096] The resin matrix is made of polydecanediamide, 30wt%, the thermal conductive filler is made of boron nitride 30wt% and magnesium oxide 20wt%, the metal oxide solid solution is 10wt%, the metal oxide solid solution solvent is tin oxide and the solute is antimony A blend of oxides, the weight ratio of solvent to solute is 3:2, other additives are 2wt% nano-alumina and 8wt% glass fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com