A Thermoset High Thermal Conductivity Insulation and Flame Retardant Composite with Laser Induced Metallization Properties

A flame-retardant composite material, laser-induced technology, applied in heat exchange materials, semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, etc. Elimination of processing steps, elimination of interface thermal resistance, good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

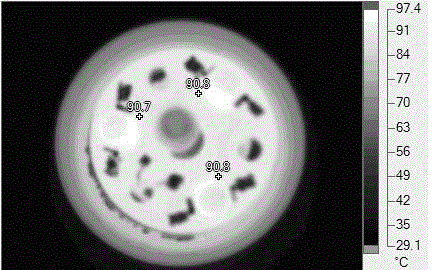

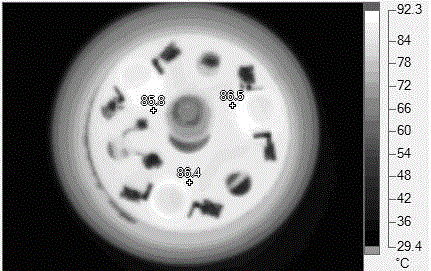

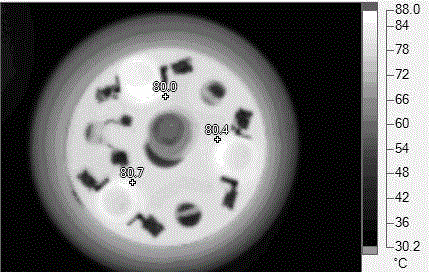

Image

Examples

Embodiment 1

[0037]A thermosetting high thermal conductivity insulating flame-retardant composite material with laser-induced metallization properties, its formula is shown in Table 1, wherein the thermosetting resin matrix is unsaturated polyester resin (epoxy acrylic resin, commercially available), and the initiator is TBPO (over Oxygenated (2-ethyl) tert-butyl hexanoate, commercially available), the internal release agent is zinc stearate, and the reinforcing fiber is an alkali-free chopped glass fiber with a length of 4-10mm and an aspect ratio of 8 :1 to 5:1, micron-scale tin-containing compounds (0.5-30μm): zinc hydroxystannate.

[0038] Materials and product preparation steps are the same as Comparative Example 1. The relevant test results are shown in Table 1.

Embodiment 2

[0040] A thermosetting high thermal conductivity insulating flame-retardant composite material with laser-induced metallization properties, its formula is shown in Table 1, wherein the thermosetting resin matrix is unsaturated polyester resin (epoxy acrylic resin, commercially available), and the initiator is TBPB (over Oxidized tert-butyl benzoate, commercially available), the internal release agent is calcium stearate, and the reinforcing fiber is an alkali-free chopped glass fiber, its length is 4-10mm, and the aspect ratio is at 8:1 to 5:1 , Micron-scale tin-containing compound (0.5-30 μm): a mixture of zinc hydroxystannate and zinc stannate at a mass ratio of 1:1.

[0041] Materials and product preparation steps are the same as Comparative Example 1. The relevant test results are shown in Table 1.

Embodiment 3

[0043] A thermosetting high thermal conductivity insulating flame-retardant composite material with laser-induced metallization properties, its formula is shown in Table 1, wherein the thermosetting resin matrix is unsaturated polyester resin (epoxy acrylic resin, commercially available), and the initiator is TBPO (over A mixture of (2-ethyl) tert-butyl hexanoate) and TBPB (tert-butyl peroxybenzoate) in a mass ratio of 1:1, the internal mold release agent is zinc stearate, and the reinforcing fiber is alkali-free Chopped glass fibers, the length of which is 4-10mm, the aspect ratio is 8:1 to 5:1, micron-scale tin-containing compound (0.5-30μm): tin dioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com