Heat transfer structure and manufacturing method thereof

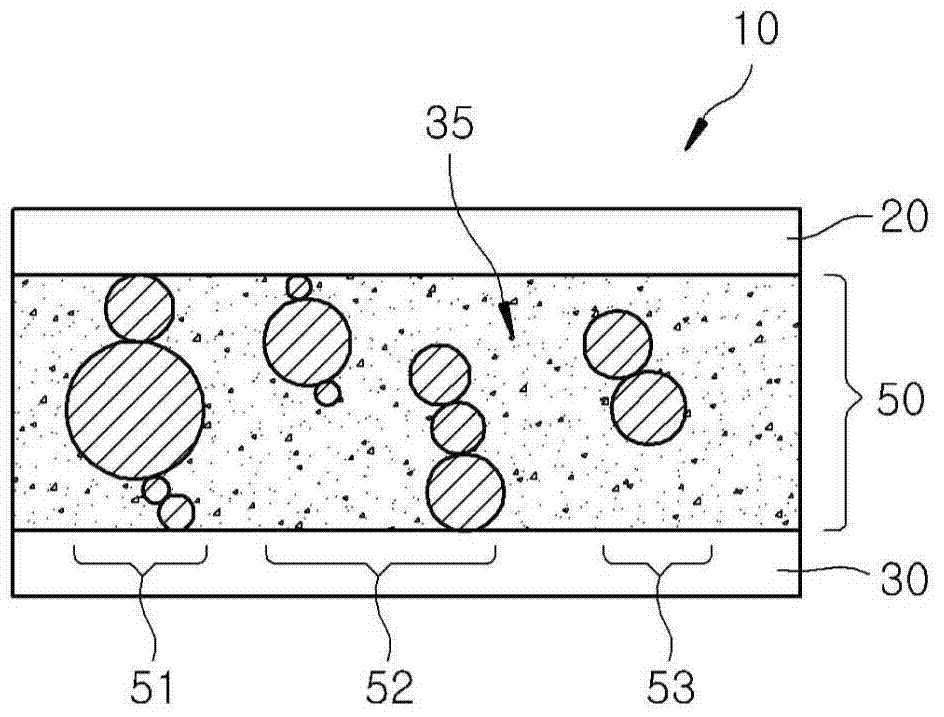

A manufacturing method and technology of thermal conductivity, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as low thermal conductivity, low thermal conductivity of TIM material 50, low thermal conductivity of TIM material, etc., to achieve Effect of increasing thermal conductivity, eliminating or minimizing interfacial thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

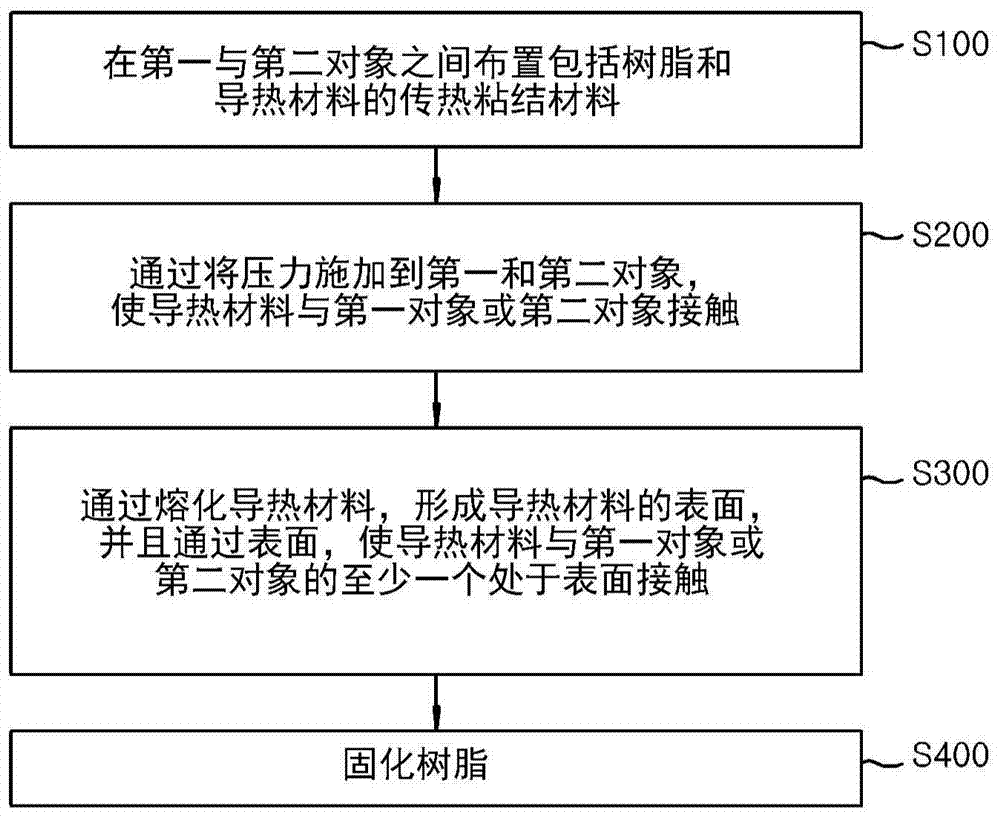

Method used

Image

Examples

no. 1 example

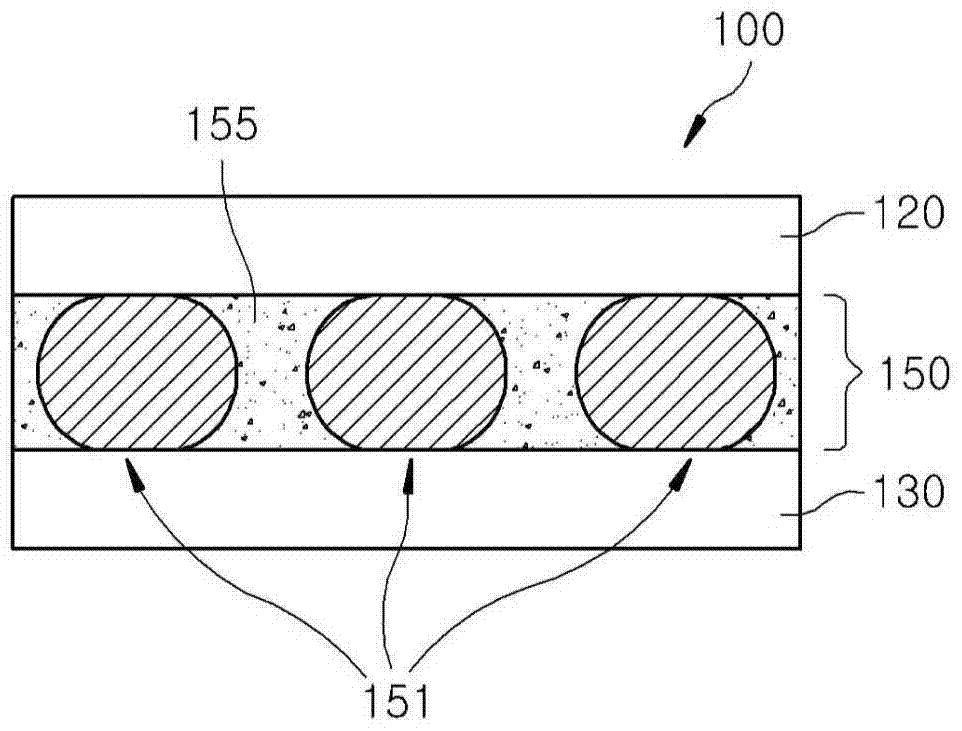

[0056] In the heat transfer structure 100 with the configuration of the direct heat path according to the first embodiment of the present invention, the heat generated in the first object 120 passes through the heat conductive material 151 consisting of only one layer and is transferred to the second object 130 . In this case, an interfacial thermal resistance on a path through which heat passes may be smaller than an interfacial thermal resistance when heat passes through a plurality of thermally conductive materials connected to each other in series. Therefore, according to the first embodiment of the present invention, thermal conductivity higher than that of conventional TIM materials can be obtained.

[0057] In addition, since at least one thermally conductive material 151 is uniform in size, in the case where any one of the thermally conductive materials 151 is in contact with the first object 120 and the second object 130, the remaining thermally conductive material 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com