Black ceramic metal full-flow-channel solar heat collector and manufacturing method therefor

A solar collector and solar collector technology, which is applied in the field of solar energy, can solve the problems of low efficiency of copper-aluminum composite flat solar collectors, problems of solar collector efficiency and lifespan, and changes in metal crystal form and crystal state, etc. problems, to achieve the effect of eliminating interface thermal resistance, improving heat collection efficiency, and fast heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

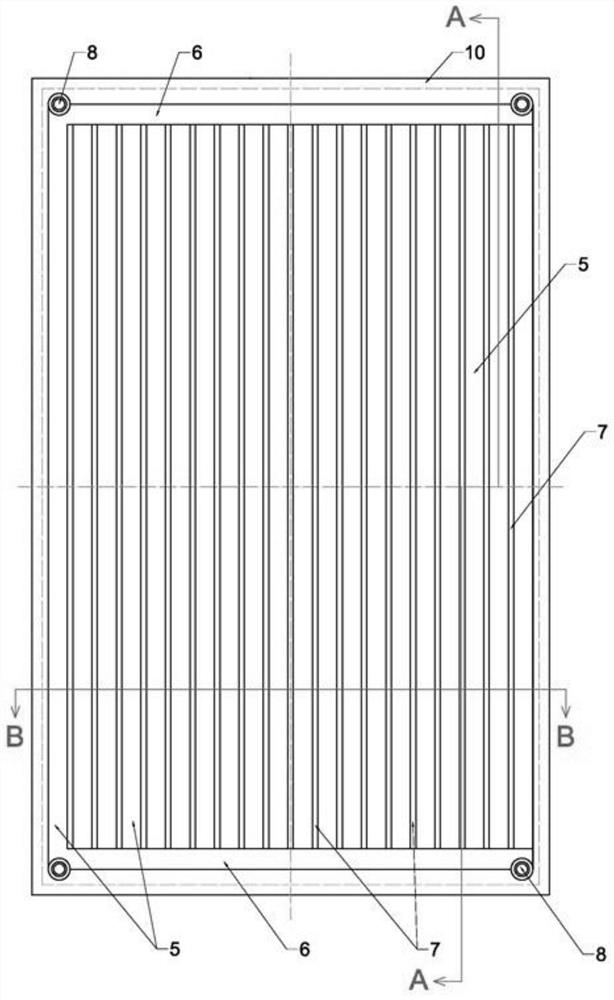

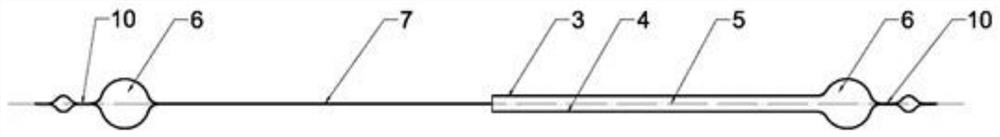

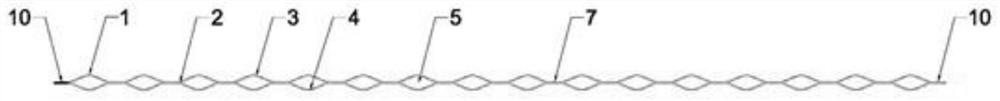

[0041] A black ceramic metal full-channel solar collector, including a panel 3 and a bottom plate 4, the material of the panel 3 and the bottom plate 4 is a rollable metal flat plate, such as copper, aluminum, stainless steel and other alloy metals, but not limited to the above-mentioned The shape of the panel 3 is the same or similar to that of the bottom plate 4. The panel 3 is provided with a number of heat collecting grooves arranged in parallel and equal in length. The collection grooves are connected with all the heat collection grooves, the collection grooves and the heat collection grooves are arranged vertically, the bottom plate 4 and the heat collection grooves of the panel 3 form the heat collection flow channel 5, and the cross-sectional area of the collection flow channel 6 Greater than the cross-sectional area of the heat collecting flow channel 5, the bottom plate 4 and the collecting groove of the panel 3 form a collecting flow channel 6, and the bottom pla...

Embodiment 2

[0055] A black ceramic metal full-channel solar collector, including a panel 3 and a bottom plate 4, the material of the panel 3 and the bottom plate 4 is a rollable metal flat plate, such as copper, aluminum, stainless steel and other alloy metals, but not limited to the above-mentioned The shape of the panel 3 is the same or similar to that of the bottom plate 4. The panel 3 is provided with a number of heat collecting grooves arranged in parallel and equal in length. The collection grooves are connected with all the heat collection grooves, the collection grooves and the heat collection grooves are arranged vertically, the bottom plate 4 and the heat collection grooves of the panel 3 form the heat collection flow channel 5, and the cross-sectional area of the collection flow channel 6 Greater than the cross-sectional area of the heat collecting flow channel 5, the bottom plate 4 and the collecting groove of the panel 3 form a collecting flow channel 6, and the bottom pla...

Embodiment 3

[0071] refer to Figure 1-3 , a black ceramic metal full-channel solar collector, including a panel 3 and a bottom plate 4, the material of the panel 3 and the bottom plate 4 is a rollable metal flat plate, such as copper, aluminum, stainless steel and other alloy metals, but not limited to the above-mentioned For the listed metals, the shape of the panel 3 is the same or similar to that of the bottom plate 4. The panel 3 is provided with a number of heat collecting grooves arranged in parallel and of equal length. The collection groove is connected with all the heat collection grooves, the collection groove and the heat collection groove are vertically arranged, the heat collection groove of the bottom plate 4 and the panel 3 forms the heat collection flow channel 5, and the cross section of the collection flow channel 6 The area is greater than the cross-sectional area of the heat-collecting flow channel 5, and the collecting groove of the bottom plate 4 and the panel 3 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com